| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Assembly of full plate watches.

Assembly of full plate watches.

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Assembly of full plate watches.

Assembly of full plate watches.Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

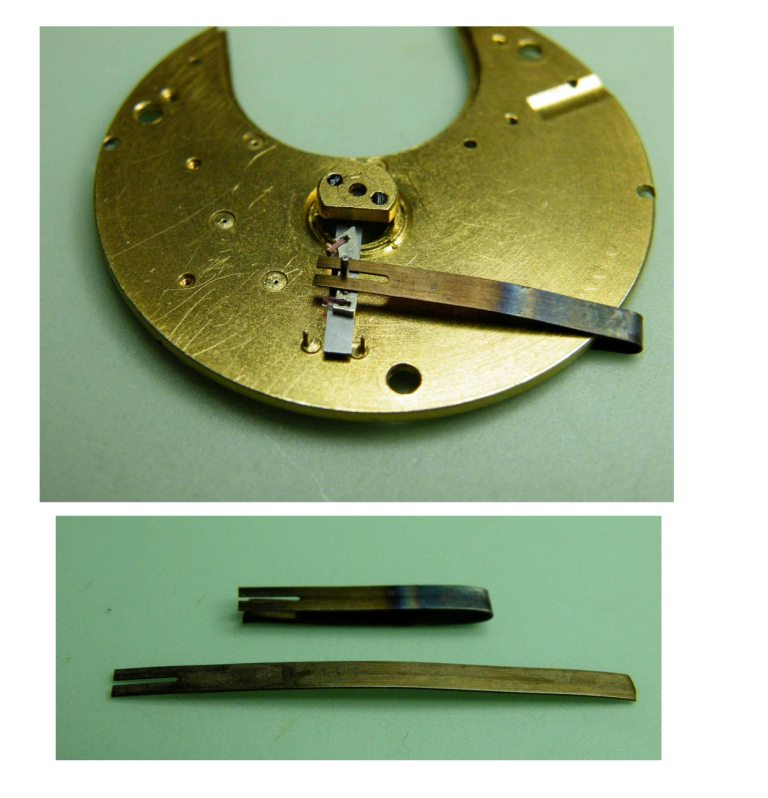

During assembly of full plate watches I am using a simple tool that I made in my company. Some mainspring part with one end cut on a wire EDM machine. This help to hold the lever. Is there a better solution? Thank you. Bulent Ogel  | |||

|

| IHC Member 376 Watchmaker |

Bulent i have made these before but i coat my with shrink wrap like you use on elect. wires too keep from scratching the movement..something else that will work is a plastic coated paper clip.. | |||

|

Good idea. Thank you Samie. Bulent | ||||

|

The correct way to assemble full plate watches is to assemble the train and lever on the top plate. Doug Sinclair described the process in this post. Larry  | ||||

|

i hold mine with a small piece of rodico pushed in from the top.is there nothing that stuff cant do? | ||||

|

| IHC Member 376 Watchmaker |

Lawrence i have tried both ways and i find the other way easier for me.. | |||

|

| IHC Life Member |

I do it the way Lawrence shows. I found it helps if I get eye level with the movement. | |||

|

| IHC Life Member |

I posted this picture about 2 years (and about 150 18s full plate restorations) ago. The rodico works every time, and as you only have to set the bottom pivot of the pallet lever or fork, it is always easy "once you get the hang of it". This has helped me immensly on the 5th pinion models which would be a real bear to do the "conventional way".  | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide