| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Waltham model 1894

Waltham model 1894

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Waltham model 1894

Waltham model 1894Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

If I have not hoplessly screwed-up my memory, Waltham grades and grade-names usually refer to the quality of a mechanism's refinement, or degree of finish. Waltham Model numbers usually refer to that date on which a specific engineering layout was used. An abundance of fudge-factor, however, abounds and is the source of my question. The Riverside 1894 model is equipped with a friction-fit balance staff. Does anyone know if a friction-fit balance staff was a feature of all model 1894 mechanisms, or if it was a 'reserved' feature for only the top-end grades? Thanks for the unravelling. - Mark Lee | |||

|

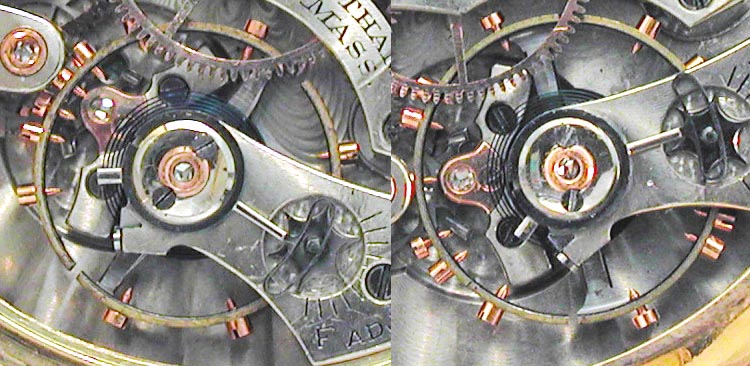

Mark, it is an age thing unrelated to grade. The first 1894 model movements had a riveted staff (and also a hook-end mainspring). You can tell which staff is used by the shape of the balance arms. The riveted staff is used on balance wheels with arms that taper gradually to the rim (left side of photo below). Friction staffs are found on balance wheels with parallel-sided arms that flare out at the rim (right side of photo). I have not done research on existing movements, but my guess is that they began to use friction staffs about the same time as the 1899 model 16-size was introduced (which had exclusively a friction staff). The change is not documented in the records. The two examples shown, both original balance wheels, are on movements that are 7 apart in serial number in the 8.7-millions.  | ||||

|

Jerry; Thanks for the information. Does 1899 represent an industry-wide shift from a riveted balance wheel to friction-fit balance wheel, or was Waltham setting a new trend? - Mark Lee | ||||

|

I believe that Waltham was not only setting a trend, but definitely leading the pack. No earlier (or contemporary) friction staffs come to mind for me. Hamilton, Illinois, Howard (Keystone), Hampden and Ingersoll all used one in one model or another, but these were several years later than Waltham's. [did I miss any?] | ||||

|

Jerry, I also thought that the friction staffs came along later, until I came across this early 1894 (ca 1895) with a friction staff. The sn on the balance matches. So... just what is the earliest friction staff that folks have found?  | ||||

|

Actually, Mike, your Riverside is from a group of 2000 movements (7310001-7312000) that were sent out from the factory over a four-year period from January 1898 to August 1902. The handwritten records list these as 17-jewel movements. I suspect yours sat unfinished in factory inventory for a year or two and was upjeweled and fitted with the newly available friction staff balance when it was finally needed. The available set of handwritten records was probably compiled in late 1902 or shortly thereafter (as I do not see any delivery dates later than that). Many of these later groups of movements (including some of the 19j Riversides) have notations about movements not delivered which I take to mean that the unfinished movements remained in inventory at that date. | ||||

|

I just took a look through all of my 12-size movements and, other than the example I showed above, I do not have friction staffs until the 10-millions, presumably 1901 or later. My own 19-jewel Riverside from the 10-millions has a riveted staff. Mike's is a nice example illustrating how some of the better grades were finished over longer time frames. As for my examples above, they are also from a group of movements finished over a longer time frame, and judging from the case style on the friction staff watch it was sold after 1910. | ||||

|

Jerry, That is remarkable! Great detective work. I hadn't thought about these sitting around unfinished for so long before shipping out. The upjewelling was cap jewels for the escape wheel pivots. | ||||

|

Mike & Jerry; Thanks for the information. I am a bit surprised that other major manufacturers took as long to follow as they did. As I recall, the year 1900 represents the beginning of 'boom-time' manufacturing. The shift from a riveted balance wheel to a friction-fit balance wheel likely gave Waltham, albeit short-lived, a bit of a production edge. - Mark Lee | ||||

|

Jerry probably has seen more of the marketing literature than I, but I believe the friction fit staff was intended for the benefit of the watchmakers rather than the factory. The factory had fixtures that made the application of the staff to the balance a very high volume production step. There may not have been any hand labor involved. | ||||

|

Tom; I think that you are right. It certainly would have been a benefit to any retail/repair watchmaker, but the factory would have benefited also. In spite of the possibility that the wheel riveting operation may have been mechanized for high volume output, a mechanized friction fit operation would have been faster. Accordingly, finished time keeping mechanisms would reach the time test phase sooner. For the individual time keeping mechanism the reduction of its production time would be moot. In terms of an entire run, however, the time savings could have been significant. Most appreciatively, the quality of the finished product would not at all have been adversely affected. - Mark Lee | ||||

|

Waltham's friction staff was introduced solely for the benefit of the watchmaker. It probably required more production effort on the part of the factory because the friction staff requires a separate hub that is riveted to the balance wheel. Furthermore, the tolerances between the hub and the staff must be very close for the friction staff to fit well. The hub is made of blued steel so that it should be apparent to the watchmaker that something is different. Waltham also listed, in their material catalog, replacement hubs for the unwitting watchmaker who did not realize he was dealing with a friction staff and drove out or turned out the entire assembly. Attached is a poor photo of a staff partly out of the hub that you can see still attached to the balance wheel.  | ||||

|

Jerry; Thanks for the clarification. I stand corrected. From your discription the use of a friction-fit balance wheel was indeed more a complex application than using a riveted balance wheel. I only hope that the watchmakers were appreciative! - Mark Lee | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide