| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Ever Wonder Why All American Pocket Watches Are The Same?

Ever Wonder Why All American Pocket Watches Are The Same?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Ever Wonder Why All American Pocket Watches Are The Same?

Ever Wonder Why All American Pocket Watches Are The Same?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

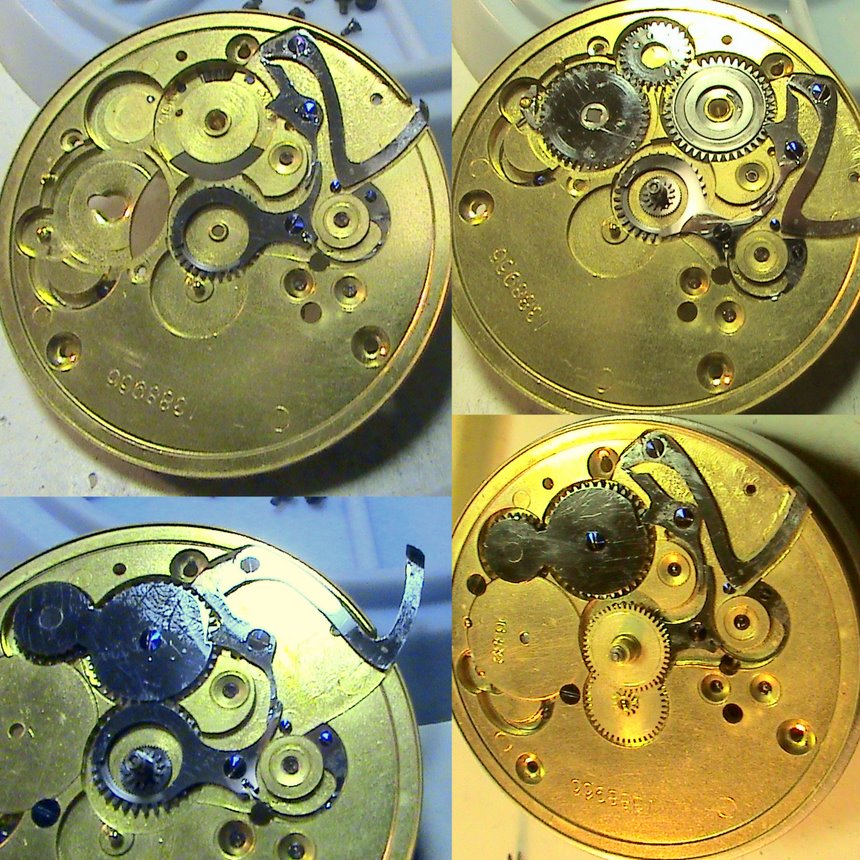

I have examples of all the big American companies in 16 and 18 sizes, except Howard. I own Walthams, Hamiltons, Illinois, Rockfords, Elgins, Columbi, Hampdens, South Bends, and plenty of Seths. I own no Swiss watches. Except for minor differences in the setting mechanisms, they are all clones of each other. They all possess a barrel and a mainspring (hanging or otherwise), a train consisting of three geared wheels, an escape wheel with an odd number of teeth, an anchor-style pallet - with the sole exception being the bar pallet on the Waltham '83 - and a balance with minor differences in hairspring overcoils. They all have a minimum of 7 jewels on the balance and pallet. They all have curb pins mounted on regulators of different styles; they all have banking pins on the pallet; they all have a canon pinion. They all run at 5 bps, or 18000 bph. I've been curious for some time now how all the bigger American companies could market toward leader-of-the-pack accuracy when they all contain the same parts list. Was it a matter of ease-of-manufacturing? A copycat issue? Or the clear winner of a long, long journey of design trial-and-error, with everybody arriving at the same conclusion? | |||

|

last sentence is your answer to your question but that's my opinion only. the clear winner of a long, long journey of design trial-and-error, with everybody arriving at the same conclusion? | ||||

|

| IHC Member 1369 |

I will side with Peter but have no real expertise. But, how many differences are there between Ford, GM and all the other car companies? Same process I'm guessing. | |||

|

I would disagree somewhat, Ralph. The guts of the internal combustion engine haven't changed much in over a century. In terms of watch escapements alone there were over a dozen. The grasshopper escapement story is fascinating all by itself. | ||||

|

now you mixing apples and oranges Eric clock escapement like the grasshopper can't work in watches Evolusion Eric ease of working mechanics. detached,detent,duplex,cylinder and so on till we perfected the one is in all watches today IMHO | ||||

|

| IHC Life Member |

Technically, all high grade American watches were fundamentally the same, with very few exceptions: A long running mainspring that would provide ample power from wind to wind, the standard gear train with its necessary mathematical divisions, proper jeweling in the critical areas and of course the venerable Swiss lever escapement along with balance/hairspring combinations that that did evolve quickly as new materials became available. All American watch manufacturers were in fierce competition with each other and all top shelf grades equipped with these things could be tuned to achieve and maintain excellent accuracy. I think it's important to mention that serviceability of these watches was always a critical concern with the manufacturers and they were careful to keep things familiar for the repairer; These machines needed to be precise, robust, reliable and readily serviceable....which they were. And still are! The guys in charge of these companies were not artisans willing to take a chance on something dramatically different, they were marketing professionals whose primary goal was to find a chance to bury their competitors. William | |||

|

| IHC Life Member |

The apparent similarities of US-made pocket Watches were actually a collation of the things that WORKED BEST in a time when (at first) the rest of the world seemed to be unaware that we in North America were even capable of making a good Horse Shoe! The early 19Th Century English "Anchor" escapement idea driving a friction-free spinning balance wheel quickly eclipsed the incredibly horrible "Cylindre" escapement preferred by the Swiss. This Free spinning design was from day 1 the De-Facto American standard due to it's easy to understand operation, efficient and super stable means of "vibrating" the Balance wheel and serviceability. Many times I have been amazed at the early American Watchmaker's "tricks" used on some U.S. made watch movements to keep them running in an occasional dearth of spare parts. But on the whole I have NEVER seen a comparably serviceable Swiss-Made movement. U.S.-Made jeweled watches enjoyed; ROBUST DESIGN (strong pivots and thick Jewels), design to size (most all SWISS stuff would fit in an 8s case and was made larger simply to impress the buyer with the size) PURPOSE BUILT wheels and jeweling (just try finding an affordable Swiss movement with a Waltham type "safety" barrel) FAST, NATIONWIDE PARTS AVAILABILITY necessary for QUICK service to assure on-time American Transportation, Industry, Communication and Commerce. | |||

|

I think it was cheaper to continue to use a proven design that worked rather than design a whole new machine that achieved the same thing in the long run. Certainly much cheaper | ||||

|

This is a good topic. It's hard to argue with the past couple comments, but I would add that for Waltham, to name just one company, big-stride unforeseen advancements were made to their effort by a handful of very clever people. Perhaps if one more genius had stopped by the factory for a spell after Duane Church, what we take for granted today would have been just a "step" in Waltham's technology. | ||||

|

All good points. To use Ralph's auto industry example, there were many differences between makes: coil spring vs leaf spring in suspension, solid axle vs Ford's twin I-beam in axles, rack-and-pinion vs rotating ball in steering, overhead cam vs direct geared in engines, gasoline vs diesel in fuel, and on and on. In American pocket watches everything under the hood is the same. The only difference was the visible stuff in plate patterns and dials. | ||||

|

If you look beyond the automatic or battery type systems in some watches then even current Swiss designs are much like the American designs in the basic forms. At some point if you have been innovative enough that all that is left is optimizing and nibbling on the corners or areas where some improvement can be made. This would have been in better materials for the mainspring and hairspring and in the balance itself to reduce the error caused by high and low temperatures but other than that there was not a lot left to improve on. The Swiss added the shock absorber jeweling to prevent the common balance pivot breakage but after that you could point to a 1900's American brand and a current mechanical Swiss watch and not see a lot of difference in the basic form. | ||||

|

| IHC Vice President Pitfalls Moderator IHC Life Member |

Not being a watch mechanic myself, I find this discussion very interesting and informative. Taking a broad perspective, it seems that there were some differences between the makes of watches, but these were evolutionary rather than revolutionary in nature, so all mechanical watches worked the same basic way. This was important if the random neighborhood watchmaker was to be able to competently service any watch that might walk through his door. Best Regards, Ed | |||

|

| IHC Member 1369 |

Gotta agree this is informative. I have read other threads about the differences between watch parts where if, as is being noted here, internal parts are the same then there would be more interchangeability - but there isn't? I don't know so pose that as a question. But, parts such as, say, a regulator spring differ greatly from one watch to another. I would guess that is in part due to the different designs of mechanisms but that would still relate to these different watches functioning the same way - needing a regulator spring - just as cars need springs but with differences by manufacturer. Yes, I agree that the basic mechanics seem to be 'similar' and probably represent the evolution to a design that represents optimal functioning. But, if everything is the same 'under the hood' why do repairs need such specific parts? | |||

|

While there was no shortage of innovative designs to the regulators - from Waltham's tadpole and gold star to Elgin's threaded crescent-shaped rolling log to Hampden's weird golf club - their sole purpose was to travel the curb pins along the stud end of the hairspring, fractionally elongating or shortening the balance amplitude. As far as parts interchangeability (like screws and jewel settings), that was probably a proprietary thing, like metric tools vs SAE. It seems like every company had a different thread diameter and pitch to their case screws so nobody else could use them, as well as irritate collectors a century later. It still doesn't answer the question of how most, if not all, the American watch companies ended up with the same parts list - except for the obvious exceptions, like dollar watches, wind-indicators, and repeaters. | ||||

|

| IHC Life Member |

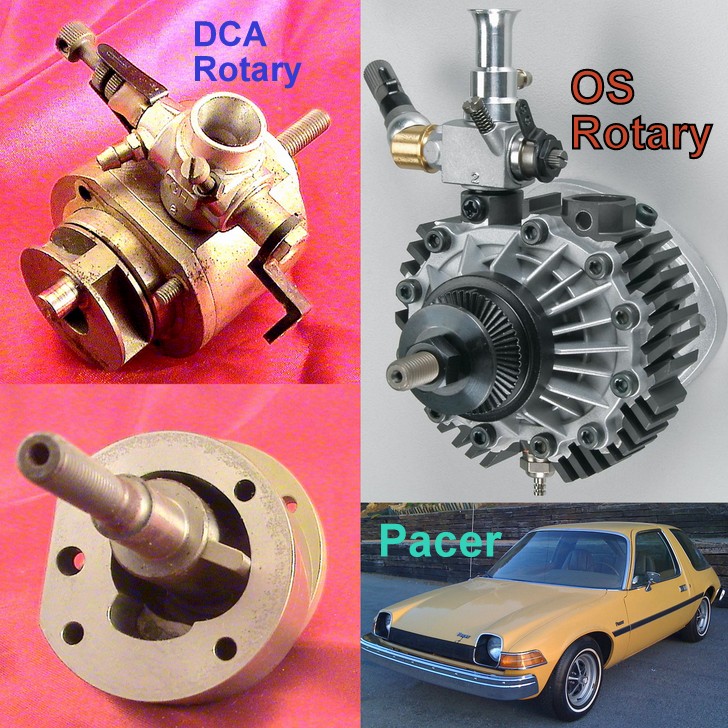

Consider 50% of the reason why the U.S. auto Industry declined to use an Engine design that when "dressed" weighed almost 200 pounds less/vehi9cle (that was being VERY CLOSE to God in the Auto industry) . . . simply put, NOBODY WANTED TO TRAIN A FIELD SERVICE FORCE TO FIX WANKEL DESIGN ENGINES! Other than that, U.S. watchmakers had a real ball with fidgeting up the Wind/Set mechanisms, some of which (like early Elgin 18s) nearly outnumbered the rest of the watch for parts count.  | |||

|

I am not sure training was an issue that prevented the Wankel from becoming more popular, emmissions, poor fuel economy, and rotor seal issues doomed the design. It was highly hyped and then the real world set in and in the move toward tighter emmissions the unburned fuel going out the tail pipe (common to this design) and the apex seal issues not even Mazda could make a go of it. I think this goes back to what the watch industry struggled with, some designs were nice from the logic point of view but from a practical point of view they did not work out as predicted. Going from a keywind, keyset to a stem wind, pendant or lever set was a major change, some found the better solutions faster than others but by the time you got to the early 1900's the design was nearly bullet proof by then without regards to brand. | ||||

|

Unlike automobiles, there is no comparable diesel engine v. standard gas engine model in portable timepieces - which isn't completely explained by the need for servicing. Automobiles have to be serviced as well. There likely was some inertia around watch machining and machinery. To revolutionize a design in place, company engineers had to have a) the impetus and ability to design an improvement that didn't upset the servicing apple cart, and b) the wherewithal (money, time, and space) to work on a problem - or inadequacy - as they perceived it. That included designing and creating the machinery to produce their improved part of the watch, and that was limited to a handful of companies and/or company engineers that could afford to do that -- so, not the Swiss cottage industry, and not the smaller U.S. companies. And I can imagine an attitudinal standoff among company officials between believing in innovation to get ahead of the competition versus the belief that "if it ain't broke, why fix it." | ||||

|

| IHC Life Member |

Claude, you are exactly right, the other 50% of the decision by Detroit Automakers to drop the Wankel was Emission and fuel efficiency problems deemed too costly too solve in US-made cars. Very sadly, the American Motors designed Pacer car that was designed for a GM-developed Wankel failed to "catch on" due to GM's decision to drop Wankel Development, forcing A.M. to use a more costly small six instead. So you had lots of windows but no guts and a higher price point. My own personal experience with Ford Engine Experimental, GM and Outboard Marine (Johnson/Evinrude?) included trying to evolve a Trochoid-Based rotor setup that could be sealed effectively. The problem WAS solved by my good friend Kazuhiro Mihara of O.S. (Model Airplane and Steam) Engines, Osaka, Japan, but of course the O.S. Wankels were running on Nitro-based Methanol fuel and had no emissions standards. "Kaz" even worked with me to design and build a simpler working Rotary Super Charger, and Two-stage Supercharged Engine. A business I started in 1986 with a friend that was sadly and suddenly terminated when my friend died of ALS.  | |||

|

That was the practical aspect of the Wankel engine, there was a sweet spot in regards to rpm range that the Wankel worked very well but if you were above or below that range (typical city driving where you accelerate and slow down) emissions and gas mileage became problematic. | ||||

|

| IHC Life Member |

I think that there's just a small chance that some of us might actually like motorized stuff more than we like watches! William  | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Ever Wonder Why All American Pocket Watches Are The Same?

Ever Wonder Why All American Pocket Watches Are The Same?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Ever Wonder Why All American Pocket Watches Are The Same?

Ever Wonder Why All American Pocket Watches Are The Same?©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide