| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  American pw clone?

American pw clone?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  American pw clone?

American pw clone?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

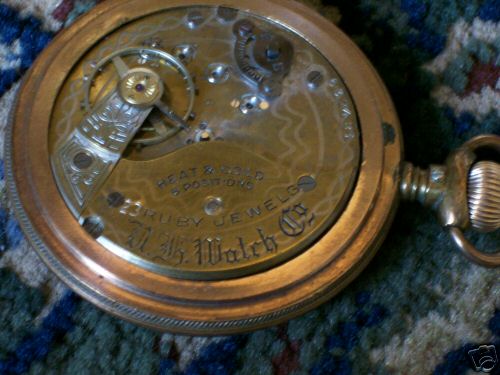

Hi, i buyed this 18s pocket watch, but i not know nothing about it. Im not sure is an American pocket watch, possibile swiss or english clone? Thank you! ( Broken gear..)    | |||

|

| IHC Life Member Moderator |

Fabrizio, My opinion is the overall watch has a "swiss fake" look to it. The overstated markings raise suspicions but the apparently non functioning regulator is a big strike against it. I can't say for certain but I'm not sure that gear device is really damaged. To my eyes it looks like someone intended to cut it that way. Others may know for sure. Don | |||

|

| IHC Life Member |

Fabrizio, that is indeed a swiss "counterfeit" US-style watch movement. The "broken gear" is a cut out part of the old wheel made when someone was attempting to repair it by soldering in a new piece of metal that they can hand-make new teeth for the winding gear. The case is worth 3 times the watch. I picture a swiss counterfeit that I bought for the case for your comparison.  | |||

|

Many many thanks Donald and David!! Now i have "fake" american pocket watch in my collection, eheh no problem i like it. Movement is working, problem is only damaged gear, and is not compatible with elgin and waltham gear. I will try solder it and to reconstruct the teeth.. not easy :-( Fabrizio | ||||

|

| IHC Life Member |

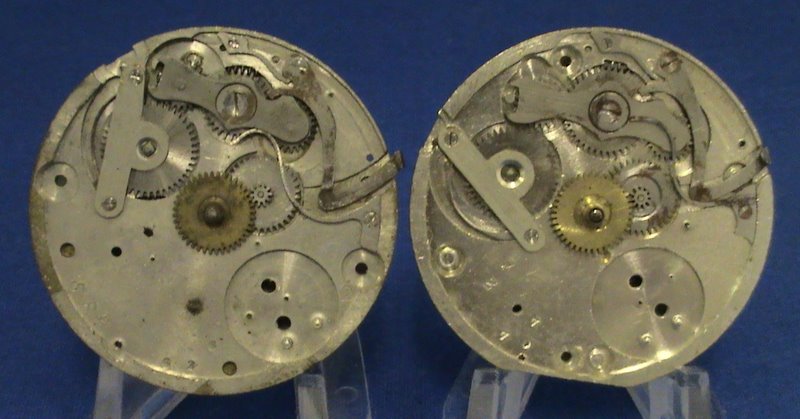

Fabrizio, I have two SDwiss Counterfeit "parts" movements that I will give you "free" if you will pay for the postage! Just advise your address and how I should send them. The smaller winding gear measures about 8.86 mm outside diameter and the larger gear measures about 11.6 mm outside diameter.  | |||

|

| IHC Life Member |

They are quite different on the Balance wheel side, but at least you get a lot of swiss conterfeit movement screws.  | |||

|

Hi David! My gear is outside 11,30 mm and hole inside 4,69 diameter, is the some of your? Now i try fix it..            At moment i not tested the gear, i not think is good work. :-( Fabrizio | ||||

|

| IHC Member |

I applaud your attempt,my friend! Everytime I try something new in repair it takes me more than one try-usually more than two,too! Don't be discouraged;show us your progress! Your pictures are great and we all learn from them-if you can't get that gear to function as it is, I'm sure with more work you will. Marty | |||

|

| IHC Life Member |

Fabrizio, I can send you the wheel. It should work for you because the thickness is 0.69mm. You can make that thickness corect for your watch very easily, and the 3.73 mm inside diameter and 11.45 outside diameter can be fitted to your watch! I would send you the complete watch movement and you could chose the parts to use to make yours work best!.  | |||

|

COOL!!! Thank you very much David!! My email is programmer@altern.org contact me and i send you address and money. Today i restored movement, damaged gear work but sometime winding is locked and non free.. i prefer your gear :-) Now movement is clean and oiled.   Damaged mainspring, i fixed it..    The case.   | ||||

|

Thank you Marty!! | ||||

|

| IHC President Life Member |

This is great! Three guys working together from California, New York and Italy is what the IHC185 is all about! | |||

|

| IHC Life Member |

After the beautiful workbench he shows us, and now we look at what Fabrizio is doing to restore that watch, we should "nickname" him "Fabrizio Di Claudio-Magnifico! | |||

|

| IHC Life Member Moderator |

You're right David, Fabrizio DiClaudio is a Fabulous Craftsman, he earned the title! Don | |||

|

Fabrizio, Your work is Fantastic! I also have a few "fakes" that I purchased on purpose too. I like all of them, even the fakes. Your movement sure turned out gorgeous, it looks almost brand new, and I admire the hard work you did on the needed parts. You have a great talent for watches, and thank you so much for showing us your work. Sheila | ||||

|

The repair looks great. i like your diligence. it is work just like this that helped bring about the name "watchmaker". How did you "solder" the piece into the gear? I think that the repaired gear is "locking", from what i can see, because in the place of the 2 cut teeth there should be about 4 or 5. Of course i bet just cutting 1 of those teeth was not to easy. Keep up the good work. If you get time look at the pics of the bridge i am making in the post "elgin sweep sec". Hey, if you dont have the part make it. | ||||

|

Thanks to all for the compliments. I am happy Many Thanks to Dave for gear and movements shipped to my house in Italy!! | ||||

|

Hi, im electronic repair of alarms systems and security cam. ( im not a watchmaker, i like repair pw of my collection, is my hobby ), i used normal solderig for circuit and chips. Is a particular solder, i read TIN/LEAD 33 % the name of product is Super Solder the best flux corf. Fabrizio | ||||

|

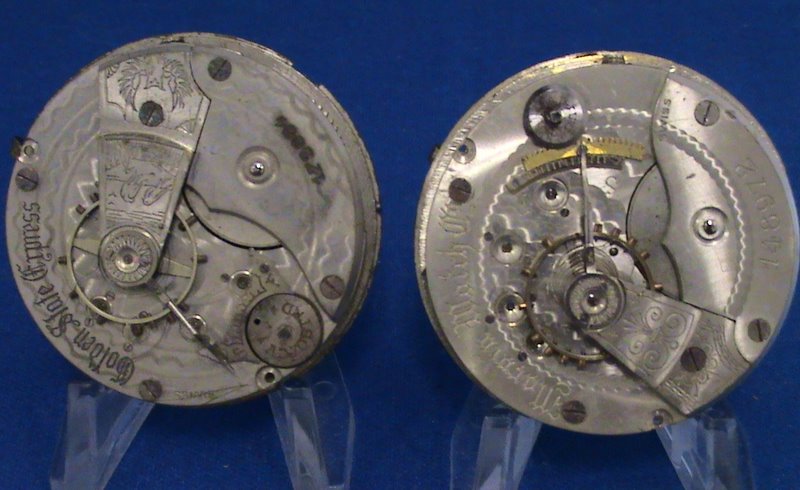

Many Thanks to David, i recived pocket watch with gear, a little modify and now is perfect! My work.. Left original gear, right David's gear, the center hole is little, i use lathe..          Now is perfect, thank you DAVID!! | ||||

|

WOW!!!!! Fantastic! It's so clean and beautiful! Great Job. Sheila | ||||

|

| IHC Life Member |

Fabrizio, with the skills and perfection you applied to this, you made a better watch than the original! Wonderful job, and I am proud to have been able to help your success with "putting the original watchmaker to shame". | |||

|

| IHC President Life Member |

What a wonderful story this is! Fabrizio, you demonstrate an outstanding level of dedication and craftsmanship that few have today. Without people like you many of these watches would be nothing more than spare parts. Lindell | |||

|

Thank you Sheila, David and The President! I'm happy read your compliments! | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide