| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Screw Head Cut In Half. Why?

Screw Head Cut In Half. Why?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Screw Head Cut In Half. Why?

Screw Head Cut In Half. Why?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

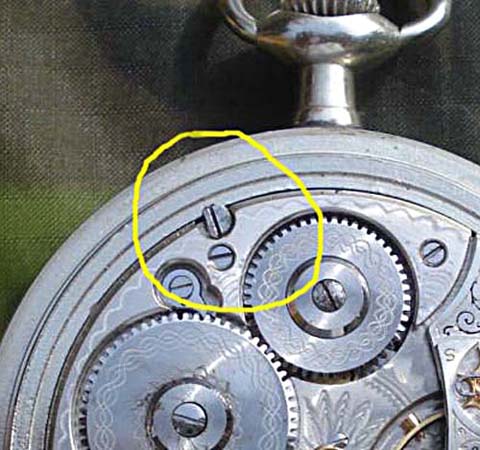

Hello everyone; I was browsing eBay just now and came across a watch that apears to have been re-cased. What I am wondering most of all is why is there a half-headed screw inside. If anyone can tell why this is done I would really appreciate it. I know nothing about pocket watches at all, but my instinct tells me that this appears to be shady. Thank you. Bud Bad Screw?  | |||

|

| IHC Member 163 |

Half head case screw? No, those can be found quite easily, and were considered a 'better' screw as they would 'bite' into the case and be less prone to loosen up in use. A 'quick fix' repairshop trick. Problem was, they DO bite into the case ledge, and cause those awful gouges you see on old cases. Sometimes after a lot of use, they actually cut the ledge out. So, nothing shady. Just an 'improvement' in the repair process, or so they surmised. Regards! Mark | |||

|

Hello Mark; Thank you very much for this information. I guess I'm beginning to worry too much now. First I didn't know anything, and now I know just enough to be dangerous. Really appreciate your reply Mark. Bud | ||||

|

| IHC President Life Member |

Bud, My belief is that all screws were made completely round and movements were originally fitted with complete screws. Apparently, in order to speed the repair process some watch repair people would clip about a third off one side of case-screws, that way they need only turn them by one-half turn in removing and re-installing the movement. Close examination will confirm the clipped screws are roughly cut and not at all uniform. Many of us consider them offensive looking and as Mark pointed out they do serious damage in "gouging" cases, we try to replace clipped screws on our nicer watches. Interestingly, there are many "quick-release" attachment devices made today, the ones I mention are spring-loaded and used in various fields including cameras, cars and motorcycles. A search of "quick release" brings up a number of modern day-products, some are high-tech versions of what was done to our case-screws so long ago. Those are my thoughts, let's hear yours! Lindell | |||

|

| IHC Member 1110 |

Hi Bud, those horrible half-head case screws are, as Mark and Lindell said, only good for ruining cases.They are the dumbest invention in all of watchmaking!By the way, the picture you showed is an 18size model 1892 Waltham, one of the nicest and highest-quality American watches.Whatever grade name or number that is, it's a keeper.Best Regards, Ted. | |||

|

| IHC Life Member |

I agree with Lindell. You might see a lot of these half screws but they are not original. They are not polished on the cut side. And would not of been shipped from any watch co. As it states poor quality. To take the movement completely apart you have to remove the case- screws any way. My assumption is that a lot of shady repairmen did this to speed there cleaning time up. Thus not even disassembling the watches completely to clean. When you do not disassemble the watch to clean it you normally have to clean it two are three times. To get them to run for very long. So by cutting the screw they are SAVING A LOT OF TIME. DUH!!!!!! | |||

|

| IHC Life Member |

Those were the same "ilk" who tossed out the dust covers, stopworks parts, and "shaved" Jewel mounts to "squeeze a fix" out of a broken staff! | |||

|

| IHC Life Member |

How do you fix that Staff David? Regards, Larry | |||

|

| IHC Life Member |

I have to find a new Mounted Jewel and then re-staff the balance wheel with a new Staff, and Pray . . . | |||

|

Bending the balance cock, gouging the underside of the balance cock and pillar plate anything to get around using a balloon chuck to dress the staff properly.....such laziness and all to save a buck and then we have the oldest one in the book ...Why would anyone in thier right mind want to steal the jewels out of a movement?? No wonder there aren't enough hours in a day.... | ||||

|

| IHC Life Member |

Here is one I found recently...Both pivots bent, not broken, so to prevent binding in the jewel hole? Bigger hole jewels of course!! What are they thinking?? | |||

|

It would take a watchmaker of moderate skill and in no hurry ten minutes to replace a balnce staff at most. I wonder some times how long a list you generate of shortcuts with bad out comes. Another one I love to see is a watch that has obviuosly been dropped the balance repaired properly but the train hole jewels still fractured. They're not thinking! | ||||

|

| IHC Member 1291 |

Hey Bud Back to the topic on the half head case screws Nothing shady, just a very poor unproven attempt to save time in the aftermarket of watch repair. The first rule of thumb in watch repair 101 is to never make shortcuts that can't be undone. So the watchmakers[if you will] were in violation of the basic rule Now years and decades later, we are the ones that suffer Anyone out there that would like to entertain such an endeavor, I'm you're Huckleberry regards, bb | |||

|

| IHC Life Member |

John, I agree with everything you say exceptin the "ten minutes to replace a Balance staff". The "average" (for me) is about 40 - 60 minutes IF I quickly find a "right" (all dimensions match exactly) staff, the Jewels are good, the clearances are good, the pivots and end-play need not be re-done and the Wheel, Roller(s), and balance spring collet all fit without "resizing". | |||

|

| IHC Life Member |

Buster, I'll SECOND that emotion.... Regards, Jerry | |||

|

My feral Amish watchmaker will make case screws for me, as on one of my two-tone Seths:  | ||||

|

| IHC Life Member |

Great looking screws on a great looking watch, Eric.... Regards, Jerry | |||

|

Yeah, Jerry, he does do an incredible job, considering his lathe is foot-powered and the fact that he works by lamplight. | ||||

|

Wow, gentlemen, I can't thank you enough for all the replies about thos nasty looking half-headed screws. I didn't like the look of them when I first saw them and still don't. However, I now see why you guys dislike them terribly and I would have to agree 1oo%. Thanks again, and I sure am glad I joined this club. Thank you for that. Bud | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide