| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Is this a decent Waltham????

Is this a decent Waltham????

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Is this a decent Waltham????

Is this a decent Waltham????Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

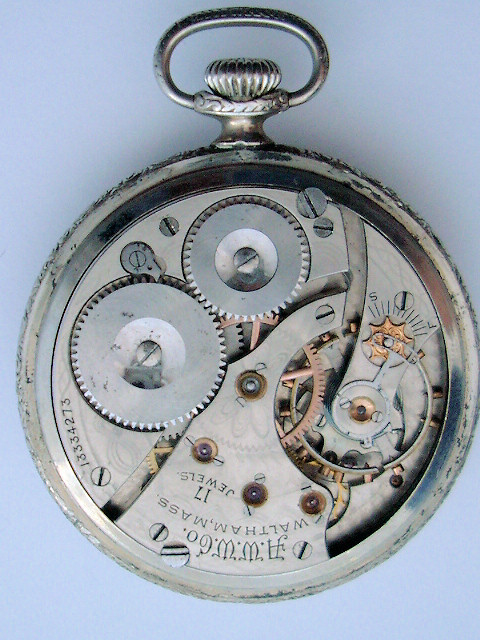

Hi Folks, Having a root around in my storage boxes, I turned up this Open Face watch I'd forgotten I had. Looks half decent (but very grubby), can anyone tell me a bit about it please? (like 'what is it' and is it worthy of note at all). The case is a screw back / bezel and quite ornately chased. Not very worn, mainly to the top edge near the glass and extreme edges on the back, bow still has plenty of chasing present. Inside the case back, it's stamped " Supreme - I.W.C.Co - 5617248" appears to be polished nickel. Overall the case is very good, with no damage at all, just a minute burr on one edge of the back where some berk has tried to pry the back of with a case knife! fortunately, no damage to speak of. Unable to screw off the bezel yet, but the dial looks as near perfect as I can tell through the glass, has painted numerals and a 'frosted' appearance to the face. Has sunk seconds and one piece dial, doesn't appear to be enamel. The movement is numbered 13334273, 17 Jewels and engraved " A.W.W.Co Waltham, Mass". All visible jewels (except the lever) are screwed in chatons with pale Rubies (?)and the balance end stone appears to be diamond. The centre wheel appears to be either gold or gold plated (or some alloy with a gold appearance)? Also micrometer index arrangement. Sorry to appear a bit dumb with this, but i know next to nothing about American watches. I've looked through the Shugart books, and the nearest I can find is on page 140, which describes it as a 16S Model 1899 or 1908 hunting, but mine is open face and the serial would suggest it's of 1904 vintage. Any comments greatly appreciated. (Apologies about the photo's, still not cracked the finer points of my camera yet). Best regards John Woolsey  | |||

|

Case Back  | ||||

|

Inside Back Cover  | ||||

|

Movement - Downside is the balance staff is broken! J.W.  | ||||

|

According to the archives, your Waltham is a Model 1899, Grade No. 625, 16size, Open Face. And the balance staff is a press in type, and is easy to replace. | ||||

|

Thanks Wayne, I'm still not a lot wiser though as I don't understand grades and models of US watches, willing to learn though. Is Grade 625 a definition of quality / standard, if so how does it place this type watch in its heirarchy? Do collectors look down their noses at this type or are they desireable to any degree. Is it worth keeping or dumping? Model 1899, is this a year of manufacture or a design code? Any idea what that centre wheel is made of? Sorry if these sound stupid questions! Anyone know anywhere in the UK where a staff can be purchased? or is it a lathe job? Best regards John | ||||

|

John, I away from my house tonight, but on Monday will look up the part number for the balance staff for your Waltham. !7 Jewels are not top of the line, but are still nice timekeepers, and may be one you would like to carry in your pocket. | ||||

|

John, Although not in the RR category, it was, and is, an example of someone's art and to my mind worth trying to repair. Wayne will produce the part number and then the search starts. It's not easy from the UK but folks are very helpful. I can provide some leads if you want them. I've just got back an 18S 1908 7J Elgin , no Railroader, but a terrifically honest watch whose balance swings loudly with the best. Is its value that which I put into it? Certainly no, but it was worth it! Just my 2c's Peter | ||||

|

Thanks Peter, I certainly agree with you regarding the watch being an example of someone's art, and I personally think the movement is quite good quality, although doubtless many will snigger at that comment. To my mind the screwed in jewel holes, diamond endstone and star regulator lift it into a different league compared to what is usually offered around - that is affordable to folks such as myself anyway. I'm assuming that Waltham's aren't too popular as they don't get too much of an airing on the forums. Even if it jumped up and bit my backside, I wouldn't know what 'RR' quality is or should be, or how 'RR' quality compares with similar Swiss or English watches with similar features, American watches like this are a big learning curve (ergo - wall maybe) for me at the moment, and part of the fun of being on this forum finding out. What is 'RR' anyway ????? (please don't feint or have a coronary at that question I'm assuming it's 'railroad' perhaps, but what is its significance, what are the parameters that lift a 'RR' watch into such strata of excellence that makes it the 'Holy Grail' of American horological excellence? Anyway, that watch is still a nice piece of kit to me, and It'll get done and cleaned up even if I have to turn the staff myself (common occurrence on Swiss and English antiques)! Best regards John | ||||

|

Hi John, This is a common staff (at least here in the U.S.) and I'm sure you'll have no problem finding someone in the group (including me) who would be happy to air mail one to you. The 1899 model used either a "straight shoulder" or "taper shoulder" friction fit staff. I'm not sure when they cut over from one to the other or, if they kept using both at the same time, what the criteria was for using one or the other. The straight shoulder is part number 4860 which comes in a pivot size of .012 and .013. The taper shoulder is part number 4861 and is available in pivot sizes of .012, .013, and .014. I've got all of them in my cabinet. We just need to figure out exactly which one you need. The 1899 model was the watch I chose to start learning watch repair with. I started out with one that was running and just needed cleaning, then went on to one that was in good shape except for a broken staff. That one became my first regular carry watch once I fixed it -- so, yes, they do make good carry watches. | ||||

|

Dave, Wayne, many thanks for your help re - the staff, much appreciated. Am I correct in assuming that there will be a specific part number for individual pivot sizes / shoulder styles? I'll get the staff out and examine it, and let you know what it's got, don't think there's a lot else wrong with it other than a good clean, although knowing my luck there may be a broken jewel. Best regards John | ||||

|

John, There are only the 2 part numbers. The different pivot sizes and grade specifications are basically additional information to select the right staff. For example, my Waltham cabinet has 6 different bottles for staff part number 4861 -- bottles for each pivot size .012, .013 and .014 in both "P" and "U" Grade. I'm assuming this watch being unadjusted would use the "U" grade. (Someone correct me if I'm wrong...) Hopefully your broken staff will have one good pivot that you can get a micrometer on. Or, maybe someone with more experience on these Walthams will know what pivot size was most likely used in this watch. | ||||

|

Thanks Dave, the muddy water's just cleared a tad I used to live near Hope (seriously, near Sheffield UK I'll take a look anyway and let you know. Many thanks again Best regards John BTW - any idea what the centre wheel is made of? is it gold plated, gold (I wish) or just an alloy that faked the look of it? JW. | ||||

|

Looks like a gold center wheel to me. | ||||

|

Dave, I stripped the watch last night to check everything over, and true to form my luck held! Ok, an update: Both pivots were broken off and no sign of the debris in the jewels, it gets better too - the roller table was loose in the bottom of the movement, and has a shabby looking brass pin fitted which appears to be a botch repair, it’s just a rough brass pin staked into a ‘D’ shaped hole directly behind the notch – I’m assuming it would have had a ‘D’ shaped jewel in there. The table is just a plain flat steel disc with no shoulder or anything, just the pin and a notch, is this usual? It does look deep enough to locate on the staff reasonably securely and straight though. The staff was loose in the balance arm with only the hairspring holding the beast in place - it fell out when I managed to pry off the hairspring (without mangling it - Some careful staking of the arm will be needed, hopefully it will poise ok afterwards! Both upper and lower balance jewels are broken and useless and the endstone has a nice crater in it, so either it's synthetic or the ex-pivot was ‘unusually' hard, looks like the end stone wasn't diamond after all Curiously there's no cap on the lower balance jewel - normal?? No sign of anything having been fitted either. Can balance jewels be had with their seats as a unit, or is it a re-jewelling job? The guard pin seems to be a brass hook affair shaped like a question mark - never seen one like that before, may also be a botch repair! One of the banking pins has also been bent over with a lever or something, why the oik didn't adjust it on it's eccentric I've no idea, perhaps he didn't want to take the dial off (which is pristine BTW). That's the worst bit over anyway, rest looks ok-ish apart from needing a good clean, doesn't actually appear to have done a lot of work. I’ve also done a (very) quick test on the underside of the centre wheel, and whatever it is that makes that gold colour isn’t gold; it immediately frothed & went green! I've several old PW's of a similar age, with balances of a similar colour, none are gold either, but the acid doesn't react at all to it whatever it is! So, yet another ‘project’ underway! Best regards John | ||||

|

Wow! Sounds like that last repairer really knew what he was doing! Your roller table sounds correct but, yes, there should be a 'D' shaped jewel in there. Is the staff hub still firmly attached to the balance arm? Or, is the reason that the staff was loose that the hub is missing? Given the expertise of that previous repairer, I'm wondering if he punched the hub out with the staff. (I can find you a picture of what this is supposed to look like if it looks like something is missing from your's.) Yes, the lower balance jewel should also have a cap jewel. Your guard pin sounds correct. I have a thought... I have a 7J 1899 parts movement. The balance swings nicely and it looks like the staff and balance jewels are in good shape. (The jewels are dirty, so I'm not 100% sure on this.) The only problem is that the roller jewel is missing, but I might also have a replacement if you want to install it. At least this way, you'll know you have a staff and balance jewels that are a matched set. The banking pins are also fine on this movement. What's missing from this movement is the mainspring barrel and some of the winding parts, but it looks like you are OK on this side. The one thing I'm not sure of is whether the material level used in the 7J is the same as was used in the 17J. Maybe one of the Waltham experts in the group will know. Anyway, if you are interested in this, send me an e-mail and we can discuss details. | ||||

|

Dave, many thanks, will mail you later on. The hub is still firmly attached ok .......but to the staff Looks like the guy punched the wrong part! The hub also has a bevelled shoulder. I've got an Intel microscope, so will see if I can get some images posted of this treat, we ought to start a 'Rogues Gallery' of 'unusual repairs' somewhere Best regards John | ||||

|

John, On page twenty five of this manual you'll see the different styles of balance staffs that were used in Waltham watches. Then you'll know what Dave is trying to ask you when he mentions staff hub and so forth. Larry | ||||

|

Thanks for that link Lawrence, a great help. I can see now which chamfer Dave was talking about, I'll get the hub off the staff and examine it. Thanks everyone for all the advice, both on and off forum, a great help, I never knew there was so much stuff on various sites. Best regards John | ||||

|

Hi All, Just a quick update to say a big Thank You to Dave Coatsworth and Rob Jones who between them have provided enough bits and pieces to revive not just this watch, but another similar movement too. It may be a while before I can sit down to do surgery on them (busy unloading wristies at the moment), but I'll post pic's of the patient(s)as they progress. Thanks again Guys! What a great bunch you all are! Best regards John | ||||

|

This was a great post and here I am discovering it after five years. Is there a tutorial avaialable on installing a balance wheel staff? | ||||

|

Hi Ken I am in the possess of replacing my first balance staff. I am currently waiting for the staff to arrive. But I am reading "The Watch Repairers Manual" by Henery Fried on how to replace the staff correctly. The book is a fantastic investment if you plan on doing any repair work. I got mine on ebay for $22. There is a good post on how to remove the staff correctly. It can be found here. Dave Abbe posted it and does a great job telling what tools he uses and how to use them to get the old staff out without damaging the balance wheel in the processes. | ||||

|

| IHC Life Member |

Just a warning, the Waltham Friction staffs go in backwards. Study Fried's book carefully and you will learn more from success than failure.  Fried_Friction_fit_staffs.PDF (89 Kb, 572 downloads) Fried_Friction_fit_staffs.PDF (89 Kb, 572 downloads) | |||

|

Thank you Dave for the link, and everything else you so graciously provide. Jim, please let me know how your replacement went. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide