| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  21 Jewels... Is there really any need?

21 Jewels... Is there really any need?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  21 Jewels... Is there really any need?

21 Jewels... Is there really any need?Page 1 2

Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

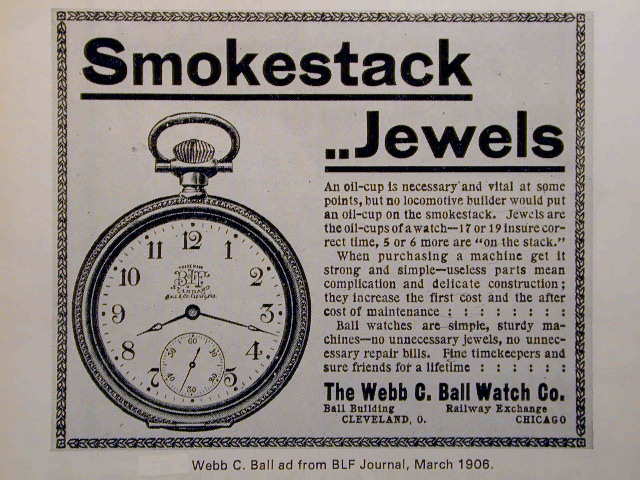

O.K. Seens to be alot of collectors after the high jewel stuff. Understandable. My question is. All things being equal, are 21 jewels all that much better than lets say 17? I am talking about time keeping and overall preformance. Not collectability or price. Some comparisons. A 972 Lever set Vs. a 992 LS. A 16s 17j BW Raymond andusted to 5 pos vs. a 21 J BWR. Are those extra cap jewels really necessary? Now, I prefer a 19j watch with a jeweled barrel. What more do you need? Plus, they are prettier with that jeweld barrel. I also want to hear from those experts on the advantages of those cap jewels. There has to be or thay wouldnt have hade them. Hey if 17 jewels was good enough for Webb C. Ball, it is good enough for me. Just something to think about. Aaron Bereiter NAWCC# 156432 Chapter 185 Charter 23 Chapter 185 Finance VP God Bless America  | |||

|

| IHC Life Member RR Watch Expert |

Aaron, As a collector of high jeweled standard watches, it pains me to have to agree with Mr. Ball. BTW, a a year or two after that 1908 ad from Ball, his ads sang a very different tune, as he had to jump on the "more jewels" bandwagon in order to keep selling his watches to both railroaders and the general public. Ed Ueberall NAWCC 49688 IHC Member 34 The Escapement | |||

|

| E. Howard Expert |

My 2 cents: It is worth noting that English pocket chronometers. which are considered by many then as now to have been the best watches made in the 19th Century, typically had 13 jewels. (Chronometer escapements had a locking jewel in the escapement in lieu of two pallet jewels and a roller jewel, as on a lever escapement. Hence, a 13 jewel pocket chronometer is jeweled equivalently to a 15 jewel lever.) High jewel counts on American watches primarily were a sales gimmick that traded on public ignorance as to how little commercial "jewels" actually cost. The value added by these jewels actually was in the workmanship of shaping and fitting the jewel, not the jewel itself. The problem that watch manufacturers faced in the late nineteenth century was that machine-based mass production had in some sense been "too" successful. That is, the factories by then could turn out large quantities of moderately priced watches that truly kept time about as well as any ordinary citizen actually needed. Thus, as my friend Tim Flower has described, in order to keep profits up, watch manufacturers found the need to sell the public on entirely new concepts of "quality" that, over time, became increasingly divorced from actual timekeeping performance. Thence came not only elevated jewel counts, but also gold wheel trains, raised gold jewel settings, elaborate damascening, etcetera. Few people would argue that the first 15 jewels all improved performance. Edward Howard flirted briefly with 16 and 17 jewels on his very early watches but ultimately settled on 15 jewels. The 16'th and 17'th jewels, usually found on the center wheel arbor holes(though Nashua cap jeweled the pallet arbor instead), may have been the last marginal improvement that made any real functional sense. (Although on keywind watches, a careless or clumsy owner can put great stress on a center hole jewel during the process of setting the hands, which may be why Nashua, and for the most part, also Howard, eschewed center hole jewels.) Additional cap jewels probably just increased the effort involved in disassembly and cleaning. Clint Geller | |||

|

I would agree with both you guys, but I do feel that the Cap Jewels do keep dust,dirt, and lint out of piviots in extreem enviorments. I cant prove this but I also feel that it keeps the oil fresher longer. That said a 15j up thats adjusted are all about the same, I don't think the Railroad man would have seem much difference in the 15j ups. The common man as myself that doesn't service his watch as much as he should I think it my protects the piviots from dirt a bit more.....JMO Not that I'm that much of an expert on watches but I have worked on mech. equipment for 25 years in the oil field and anything that produces a better seal such as a cap jewel keeps dirts out and the lub from drying longer. | ||||

|

Nifty discussion of in what ways jewels over 15 might do good. Also interesting is the question of in what ways jewels over 15 might do bad. Dr. Clint Geller says “Additional cap jewels probably just increased the effort involved in disassembly and cleaning.” Anything else? Fragility? | ||||

|

I'm with Doug on this. The cap jewel certainly reduces the friction in dial-up or dial-down positions (look at the balance wheel), and I believe this is of benefit for the escape wheel and pallet fork. The rest of the gear train moves slowly enough (and accordingly has more power to it) that there is probably no measurable benefit to a cap jewel. | ||||

|

I believe one of the benifits of the cap jewel is that you can use parts with conical pivots, which would mean less friction. Brian C. pwpartsetc@webtv.net | ||||

|

| Watch Repair Expert |

For what it's worth, almost every 15j pocket watch I've ever serviced, has had badly worn center wheel pivots. If an owner allows one to run until it stops, the friction sometimes cuts the center pivots nearly in two. Needless to say, jeweling the center wheel definitely does perform a functional purpose! As for cap jewels in the escapement, those do reduce friction at a critical point, but they serve an even more important function. The main purpose of those is to provide an "oil bath" environment for the pivots running in them. With plain hole jewels, oil tends to "migrate" out of the jewel hole, and into the pinion leaves. With cap jeweled holes, that doesn't happen; the surface tension of the oil suspended between the jewels keeps it in proper place to perform its job. ========================= Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

Clint,do you have photos or even a drawing illustrating the aforementioned English chronometer escapement? I would love to see one! Sam Williamson NAWCC 154312 IHC Charter Member 14 Member Chapters 96 and 185 | ||||

|

| E. Howard Expert |

Very interesting comments from everyone. A few more thoughts that these comments have stimulated: First, one should think that the differences in mainspring requirements for similar 7 and 23 jewel Waltham movements would result not only from the nature of the bearing surfaces on the pivot holes but from numerous other quality differences in their construction, not the least of which would be the tolerances allowed in manufacturing and assembly. Certainly, there should be no noticeable difference in friction between otherwise identical 19 and higher jeweled movements. As for cap jewels retaining oil better, I must preface my remarks by saying that I am not a watchmaker. However, skilled watchmakers have advised me that when a watch is properly oiled (specifically, when it is not over-oiled), the oil will stay in place just fine with or without a cap jewel. Furthermore, given the chemical instability of 19th century oils, a properly serviced watch should have been cleaned and re-oiled sufficiently frequently that migration should not have been a problem. I see no argument with the proposition that cap jewels offer clear advantages for balance and lever arbor pivots, but from the escape wheel on up, this "advantage" gets increasingly theoretical. You're on the assymptote of diminishing returns, which is why it is impossible to say definitively that "additional cap jewels offer absolutely no advantage." Now, did they justify the increased movement price? About that we might be able to say something. I too have seen 15 jewel movements, mostly Howards (which are mostly what I have looked at), with badly worn center holes. However, we are looking at watches that are over 100 years old. If it took 30 or more years of service for the problem to develop, then the advantage was pretty marginal. The engineering trade is between a more wear-resistant wear couple, and a more fracture-resistant bearing surface. As one approaches the main wheel, rotational speeds decrease, making wear less of an issue, and stresses increase, making fracture more of an issue. Nevertheless, on stemwind watches, I would tend to agree that it is better to have, than not to have center hole jewels. On keywind watches, the possibility of fracturing a hole jewel during hand setting may tip the scales the other way. I believe that is the reason why early AT& Co. Grade Model 1857 Walthams, which set from the front, had center hole jewels only on the pillar plate side (where they couldn't even be seen by the customer). Similarly, Nashua cap jeweled the escape wheels on their 19 jewel watches instead of jeweling to the center. Sam Williamson asked whether I had an illustration of a spring detent chronometer escapement. Alas, I must apologize that I do not have one handy. There is an illustration, albeit not a great one, of a marine chronometer with such an escapement in Mike Harold's Supplement # 14, "American Watchmaking: A Technical History". It is Figure # 2.(There are at least a thousand other good reasons for anyone serious about American pocket watches to own this book, so if you don't already have it, buy it. It is the single best general historical reference on American watchmaking either in, or out of print.) The definitive work on the subject of marine chronometers is "The Development of the Marine Chronometer," by Rupert T. Gould. Marine chronometers and so called "pocket chronometers" have the same escapement. Clint Geller | |||

|

If I can figure out what a "cap jewel is, maybe I can understand all this...... Sorry bout that some guys don't know the parts like me, thats why I'm here to learn I just need to see a difference from a capped and not capped to figure this out NO, I'm NOT Blonde Mike Nardick | ||||

|

| E. Howard Expert |

Hi Mike, The only foolish question is the one not asked. There are 2 types of jewels associated with the pivots of wheel arbors. Hole jewels, as the name implies, are pierced. The idea is for the end of an arbor pivot to turn inside the hole. Jewels are harder than steel and much harder than brass, and thus, a jeweled hole will hold its dimensions over time much more closely than an unjeweled hole. Sometimes, cap jewels, which are not pierced, are set above (or below) the hole jewel. As others on this thread already have explained, the cap jewel helps control end shake and may also aid in oil retention and may further reduce friction. Clint Geller | |||

|

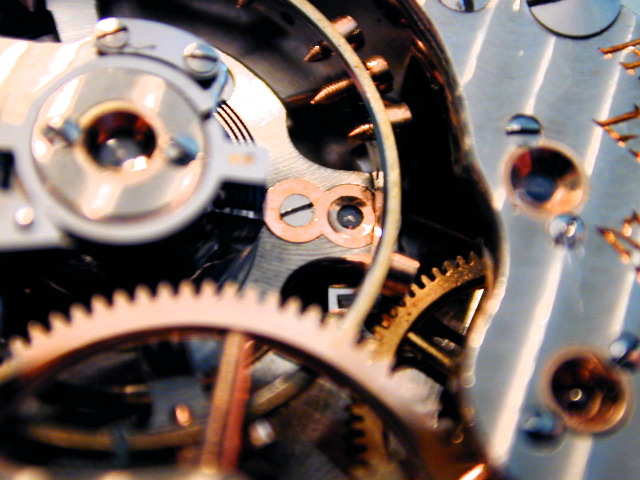

Mike, Lindell posted a couple of photos earlier in another thread that will work well here. I hope he dosent mind. The following photo is of a 956 17j Hamilton. If you look at the pallet bridge you can see the ends of the pallet fork pivot protruding through the jewel. This is uncapped. Also take note of the escape wheel pivot. It is uncapped also. The second photo is the same shot but on a 992. Note you cannot see the ends of the pivots protruding through the jewels. These are capped on both the back plate and the dial side. This adds two pair of jewels thus making up the difference between 17 and 21 jewels. Aaron Bereiter NAWCC# 156432 Chapter 185 Charter 23 Chapter 185 Finance VP God Bless America [This message was edited by Aaron Bereiter on June 29, 2003 at 21:41.] | ||||

|

Thanks for the help Guys, They still look much alike to me, Mike Nardick | ||||

|

Me too, sad to say. | ||||

|

Hey Mike and Dog look on page 72 of Suggarts (2003) it shows a picture that will give you an idea (bottom right). As you see there are 2 jewels in the setting when a pivot is capped. | ||||

|

| <Doug Sinclair> |

Dr. Geller, You may have helped prove my point about higher jewel watches operating with less friction. If there were other differences in the parts of low jewel watches as compared to high jewelled watches that meant stronger mainsprings had to be used, the watch companies did what they had to to reduce the friction for watches that had to meet higher standards. That may have involved better finished, better fitting parts, higher polish at points of friction, and on and on. But difference in the number of jewels was also a factor. Perhaps not the only factor, but a factor nontheless. As a watchmaker for over 50 years, and an avid collector and restorer of high jewelled watches. I can tell you that anyone who says an uncapped jewel will hold oil as well as a properly cleaned, properly lubricated capped jewel, is not very observant. Doug S. | ||

Thanks ttown. I understand the drawing (page 71 in my Shugart 2002) but I’m still having trouble telling capped from uncapped in photos. What I probably need to do is get a watch with more than 17 jewels so I can compare it in hand with a 17-jeweler. | ||||

|

| IHC President Life Member |

Everyone, I believe there is some confusion as to what we are pointing to in the enclosed pictures. The pallet bridge is located directly under the balance wheel, and the jewel is in the very center of the picture. The first picture below is of a 17-jewel Hamilton 956 to compare with a 21-jewel 992 example in the second picture which follows. At the focal point in the VERY CENTER OF THE PICTURE is the uncapped jewel in question...  | |||

|

| IHC President Life Member |

Capped jewel is in the big gold setting in the CENTER OF THE PICTURE with screw to the left.  | |||

|

| IHC President Life Member |

Look carefully at the pictures above. As Aaron stated of the the pallet fork pivot jewel is in the VERY CENTER of both pictures, and the escape wheel is in the RIGHT CENTER. In both instances on the 17-jewel they are uncapped, whereas on the 21-jewel version both are capped. Hope this helps to clarify the situation. | |||

|

In the photos the pallet fork pivot end on the 992 appears to my aging and ignorant eyes to be just about as prominently visible as the one on the 956. If that’s so, the cap jewel must be transparent. If the cap jewel’s transparent, how can I tell it’s there? | ||||

|

| IHC President Life Member |

When I took the two pictures above it was to focus on the pallet fork jewel in the center of the picture. That's why that jewel in the VERY CENTER OF THE PICTURE is in sharp focus. There is ONE cap jewel in the top (17-jewel) picture, the center of the balance. On the 21-jewel example THREE are shown, the balance, pallet fork jewel and the escape wheel. In order to understand the purpose of cap jewels, which is one of the most important points made above in this thread, consider them as being designed to cover and prevent dirt from entering the pivots. You can see them in the above pictures. Think of it this way, when someone wears glasses, can you not see the lenses? One of the most fundamental oversights in "production" watch repair is neglecting to properly clean the cap jewels. That is part of Mr. Ball's point about their requiring additional work. One must also consider that with the required annual tear-down and service the watches subject to time inspection were serviced so regularly the cap jewels may have seemed less important then. But for a better explanation and opinion on that I defer to our experts. Hope this helps, Lindell | |||

|

| IHC Life Member |

This slide shows a cap and hole jewel from the balance bridge of a 17J Elgin: Helping Hand Slide 10 John D. Duvall NAWCC Member 144772 NAWCC IHC Happy Camper 192 Chapter 185 Watch Repair Moderator | |||

|

| Watch Repair Expert |

Doug Sinclair is right that capped jewels will retain oil better than uncapped ones. I am a watchmaker of considerable experience myself, and I can affirm that fact with 100% certainty. For one thing, consider the evaporation factor; a properly oiled capped jewel will hold at least 4 times as much oil as an ordinary hole jewel, and all other things being equal, that would take 4 times as long to evaporate. Of course, the fact that the jewel is capped (and therefore covered) also tends to reduce evaporation, and extend service life. As mentioned above by me and others, added benefits include reduced area of frictional contact, protection from particulate contamination, better oil retention against migration, etc. In short, capped jewels are better for many reasons. A watch without extra cap jewels will run for a long time if properly serviced, but one with them will run longer, and for longer durations between service. Very few people today have any idea how many jewels a Rolex wristwatch has, but ALL modern Rolex watches have cap jeweled escape wheels, etc. It's not done just to "pad" the jewel count, it's done because it really is better, and serves a functional purpose. I presume everyone here knows what a cross section of an ordinary pivot and an ordinary jewel would look. The cap jewel is represented by the red trapezoid at the top of the image; the hole jewel (in this case, an "olived" jewel) surrounds and supports the pivot, which is shown in black. Oil is shown in green, and the cross sectional view shows how it suspends itself between the jewels and around the pivot, when properly oiled. As for the idea that a center jewel in a key-set model might break while someone was trying to set the time, I seriously doubt that. Jewels are well supported radially, and it would be much more likely that the center staff would break sooner than the jewel (and that does occasionally happen). Train jewels are typically broken by careless and/or unskilled workmen, who screw the plates together without having the pivots aligned in their holes, or who exert excessive diagonal force on a pivot in a hole while the plates are apart. As for Nashua watches, if they cap jeweled the escape wheels on their 19 jewel models instead of jeweling the center, how did they arrive at 19 jewels? Unless the pallet was also capped, adding caps to the escape wheel without jeweling the center wheel, would turn a 15 jewel model into a 17 jewel one. For what it's worth, high-grade watches tend to have higher survival rates for the same reason that Rolls Royce automobiles have higher survival rates than Chevrolets. Not only was it a matter of a superior product, but by and large, they were owned by people who could better afford to maintain them, and they were treated better for longer periods of time. It simply wouldn't be reasonable to think that a typical 15 jewel Elgin or Waltham, would receive the same attention as a typical E. Howard. Hope this helps! ================== Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

I think I've got it! By George I've got it! Thanks for all your saintly patience. | ||||

|

| E. Howard Expert |

Hi again, In fact Nashua 19 jewel watches, as well as the earliest American Watch Co Grade 20 Size KW watches, had cap jewelled pallet arbors and escape wheels and were not jeweled to the center. As for careless owners not being able to break hole jewels, I think one can underestimate the stress that can be put on a center hole jewel by careless, fumble-fingered, arthritic, bleary- eyed, or poorly sighted owners, of which there were many. Collectors and watch makers are usually pretty csreful when they wind their watches. A watch that served its owner every single day did not usually enjoy the same TLC. When setting from the dial side, all the downward force is pushing that pivot against the top plate hole jewel. Unfortunately, the only way to test this theory would be to destroy an original jewel setting. The theoretical arguments in favor of cap jewels have been well presented. However, beyond the escape wheel, the advantages get increasingly marginal quickly, especially with 19th century animal-based oils that require frequent replacement anyway. Up through some time in the late nineteenth century, the British reigned supreme at the Teddington/Kew timing competitions, and their watches typically were not highly jeweled. Clint Geller | |||

|

| E. Howard Expert |

Doug Sinclair wrote: "...I can tell you that anyone who says an uncapped jewel will hold oil as well as a properly cleaned, properly lubricated capped jewel, is not very observant. ..." Perhaps so, but that is not, in fact, what I said. My point was that uncapped pivot holes beyond the escapement hold oil well enough to serve their purpose. A cap jewelled pivot may hold more oil, and may therefore, in principal, run acceptably for a longer period between cleanings (assuming the oil remains stable). But that doesn't necessarily make for a better performing or longer lasting watch in practice. Consider Ball's pragmatic viewpoint on the subject already cited above. He could have ordered and sold watches with any number of jewels he wanted. Consider also that there are sources of friction in a watch other than those in the wheel train. Specifically, as watchmakers know well, the lever escapement itself requires draw (involving a frictional loss) in order to lock. When one considers how quickly the angular velocities decrease as one moves away from the escapement, it is not hard to believe that other sources of friction render insignificant any hypothetical advantage derived from, say, a cap jeweled third wheel. Clint Geller | |||

|

| Watch Repair Expert |

Consider this: with a typical key-wound watch, which activity is more stressful and more frequently required, winding, or setting? Obviously, winding is both more stressful and more frequently needed, and fumble-fingered owners who might be prone to damage their watches with the key, would be statistically more likely to do so while winding. Now, consider the number of fusee movements that had jeweled winding arbors. I certainly wouldn't claim to be a fusee "expert," but in my experiences, I'd bet that at least 10% of all fusee watches had jeweled winding arbors, and as far as I can recall, I've never seen one of those that was broken. It would almost (note, I say *almost*) be worth it as an experiment to "wrench" on the center pinion of a junker with a center jewel, and see which breaks first, the jewel, or the arbor. As long as the plates are firmly screwed together, my bet is going to be on the arbor. ========================= SM Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

Another 2 cents...... I must agree with Steve M. I am not an expert but have cleaned and oiled at least 100 of those fusees with jeweled fusees. I think I may have seen 1 with a cracked jewel, but I would not conclude the crack came stricly from winding..Watch was pretty rough... That part about setting with a key is somewhat overstated as I also have not encounted to may key winds that the hand setting was all that hard, to crack a jewel. I have seen broken setting arbors on the set from the rear Swiss movements...What happens to the wear particules from staffs or arbors in open jewels and in capped jewels. Wouldn't capped jeweling tend to make a mixture of "filings" and oil???? Regards, John Pavlik | ||||

|

The 21 jewel debate has been something which has been of some interest to me as to many of you. The phrase referring to 17 jewel watches as being "fully jeweled" early on led me to feel that 17 jeweled watches were likely just as durable and equal to 21 jewel or higher movements. As I think many of us agree that is debatable. The reasoning for caps jewels on the balance is obvious. Escape wheels certainly benefit from the "oil bath" provided by the cap jewels, but how about pallets pivots? Do they need caps jewels? I think most repairmen agree that the pallet pivots should not be oiled so therefore the "oil bath" is not needed. So what is the benefit? As it has been suggested cap jewels helps to keep dirt from mixing with the oil. Are there other benefits to cap jewels on pallet pivots? Many pallets arbors are conical. Do the caps jewels help to control the endshake in the pallet arbors and keep oilived jewels and arbors properly aligned? If this is the case this would also help in friction reduction which would increase overall performance. Any feedback would be of interest to me or other benefits to cap jewels on pallet pivots. Thanks, Rob [This message was edited by ysub9 on July 04, 2003 at 20:00.] | ||||

|

| Elgin Watch Collector |

Rob: I agree that it is puzzling to see pallet-forks with cap jewels, considering the debate about whether they should be even oiled. However, it is my understanding that this debate centers more around smaller wrist watches than pocket watches. The smaller the parts, the more significant the drag from the oil will be. Elgin, for example, in their ca 1910-1915 Service Bulletin on Cleaning and Oiling Watches recommends that you oil the pallet jewels. This was more than a decade after 21j watches became common. I realize that I'm posting *very* late to this thread, but my thoughts on the subject of the need for more than 15 jewels and the relationship between the number of jewels and the quality of the watch can be found found at: Jewels in Watches. The Elgin Watch Collectors Website | |||

|

| Powered by Social Strata | Page 1 2 |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  21 Jewels... Is there really any need?

21 Jewels... Is there really any need?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  21 Jewels... Is there really any need?

21 Jewels... Is there really any need?©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide