| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  How dumb is this mainspring idea?

How dumb is this mainspring idea?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  How dumb is this mainspring idea?

How dumb is this mainspring idea?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Member 2030 |

I am new to this. Thinking to save a scrap learning/practice Gilbert clock mainspring by reforming the loop end. About 6" was snapped off when I got it. I saw this quote in another post, would this work for mainspring? Then rivet? Thanks Mike Quote: Heat the spring end to bright cherry and IMMEDIATELY!!! plunge it into a five gallon bucket of cool water, swirling it around in the water as you plunge it. (Remember, a large volume of water is important - the old blacksmith used to quench a single horseshoe into a 55 gallon barrel of water). Polish the surface, so you can watch the colors. Reheat to draw the temper at a dark blue, and quench in automobile motor oil. | ||

|

| IHC Member 1736 |

You have fun with that... let us know how it goes. | |||

|

| IHC Member 2030 |

Hoping for a metallurgy lesson from Mr. Booth. The .75 width and 0.180 thick spring would succomb to manipulation after this treatment? | |||

|

| IHC Member 2030 |

Went ahead, maybe it won't be too dangerous. Before pic. Yes it was in the movement with an aluminum rivet splice.  | |||

|

| IHC Member 2030 |

After. I will tie the movement to a tree out back when testing this spring.  | |||

|

| IHC Member 1736 |

Good stuff Mike, Time Savers probably has a new spring for about $10... it's the small purchase fee and shipping that kills me. I don't see why that wouldn't hold up well. The only compromise is that it will take a couple hours off the run time of the clock. | |||

|

Yes Paul, I'll second that. Nice job Mike! I've seen clocks with previous repairs to springs that looked pretty sloppy, but they ran! In earlier days prior to internet before it was quick and easy to ask for advice, the old timers made a lot of improvisations with what they had. Dave Turner | ||||

|

| IHC Member 2030 |

Thanks for the support. I will "spring" for the new springs when the two Gilbert tambours and the amandine get redone. This was just for learning. Then on to the PW's. It is great to have this site as a resource, I will have plenty of questions as we go along. It is running like a champ! This will be mounted on plexiglass for skeleton display. Mike  | |||

|

| IHC Member 2030 |

Better pic. Brass says '23.  | |||

|

| IHC President Life Member |

Nice work Mike, It is nice to see the movement saved and that will be a very interesting conversation piece. Be sure to show us the completed project right here in this topic! Lindell | |||

|

| Life Member |

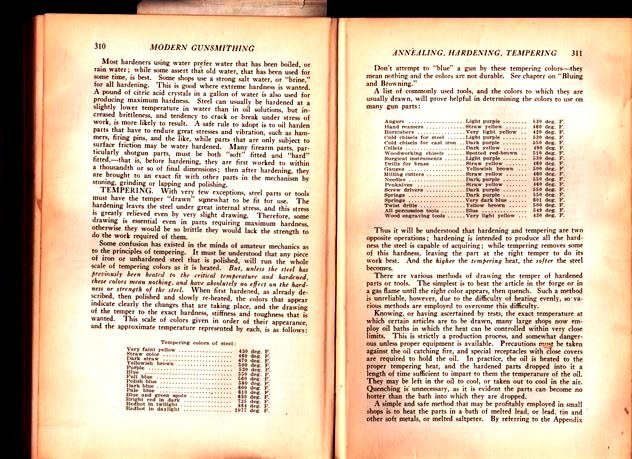

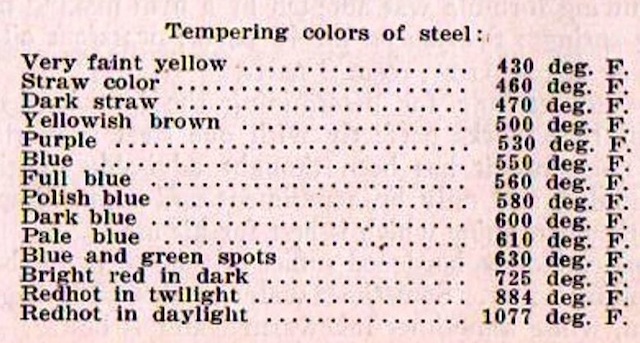

That quote from me was correct insofar as it goes. I have had mixed success with re-forming hole end springs for French clocks, where a heavy-handed winder tore out the hole, but have never tried to repair a loop end spring, as they are readily available new. (Hole-end springs are, too, but in a limited range of strengths.) Attached are some handy charts, and two pages from a long-out-of-print book, Modern Gunsmithing, with a good discussion on tempering. Remember, the process I described was for hardening and tempering. In order to work on the spring it must be annealed. That requires heating it to its critical temperature, and allowing it to cool SLOWLY! Here is how we used to do that to make leaf springs for antique firearms from old automobile spring: Using your wife's best pie pan and some sand stolen from your kid's sandbox, bury the spring in the sand, and lay a polished bit of spring on top of the sand. Heat the whole shebang over the gas kitchen range, until the spring lying on top is dark cherry (not bright red - it is exposed to the air, and is therefore about 100 to 200 degrees cooler than the internal spring you are working on). When the "tell tale" spring you can see is just red enough to tell it is no longer dark, turn off the heat, and allow everything to cool to room temperature. Alternatively, you can sometimes anneal just the end of the spring where you want to work on it by wrapping it in iron wire, and heating it with a propane or gasoline blow torch. Some springs will anneal that way; some will not. Ya pays yer money, and ya takes yer chances.  | |||

|

| IHC Member 2030 |

My granny always said "if you're gonna be dumb, you better be tough". I will rework this spring or better yet get a new one. Thanks | |||

|

| Life Member |

Looks like I have to post the images one at a time. Here is the chart of tempering colors/temperatures (degrees Fahrenheit)  | |||

|

| Life Member |

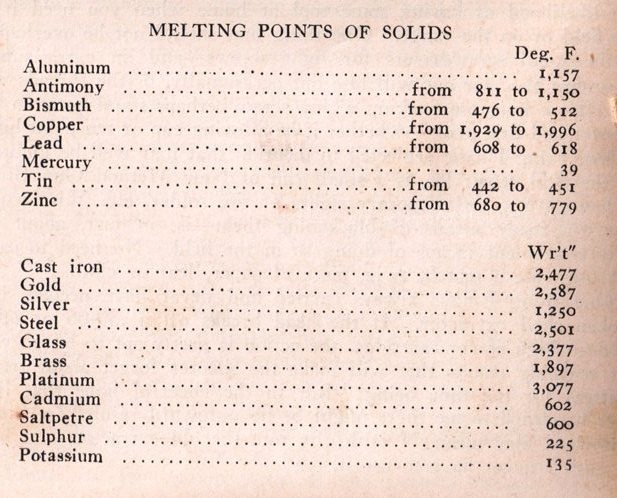

And here is one, showing melting points of various materials, if you want to use a bath to temper various items:  | |||

|

| Life Member |

...and here is a pretty good discussion online about hardening and tempering. Remember, though, the author is interested in making an edged tool - he draws the temper much lower than you would for most watch or clock parts. But if you want to make your own gravers ... Incidentally, when I worked for Mr. Devilbiss, he used to make his own riffling files, for working on restoration of firearms. (We did a lot of work for the Smithsonian and for the US Naval Academy Collection) He used pieces of automobile springs that were already curved in the form he wanted, ground the surface with a coarse grindstone, to create a cutting surface, and re-tempered them at a straw color. A Woodworker’s Guide to Tool Steel and Heat Treating . | |||

|

| Life Member |

MIke, I think you are well=-advised to "spring" (all puns intended) for a new one. It wont' set you back nearly as much as repairing te broken pats of the movement or case it your repair does not hold. And it won't hurt you narly as much as it would if the spring breaks loose while you have your hand on the winding key! Try, if you can, to get one of the replacement springs made in Germany. (Sometimes they are in short supply or unavailable and back-ordered for up to several months.) The springs made in India vary all over the map for quality control. I have had some that when I took them out of the shipping wire to clean the protectant off them, were so soft they only opened up about a quarter of an inch in diameter. Incidentally, that spring you have is "set"; the inner coils are not opening nearly as far as a new one should. IF you ae going to mees about with clocks with any seriousness, hang onto that old spring - you never know when you will need a piece of high carbon sheet steel to make a part or a tool. The metal cutting wheels they sell for use with high speed rotary tools do a great job of cutting those springs. (But wear a face safety shield and heavy leather gloves, in case the wheel decides to break apart while you are using it. You don't want to know how I know this.) | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide