| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Very Old Wood Case Cincinnati Time Recorder

Very Old Wood Case Cincinnati Time Recorder

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Very Old Wood Case Cincinnati Time Recorder

Very Old Wood Case Cincinnati Time RecorderPage 1 2

Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

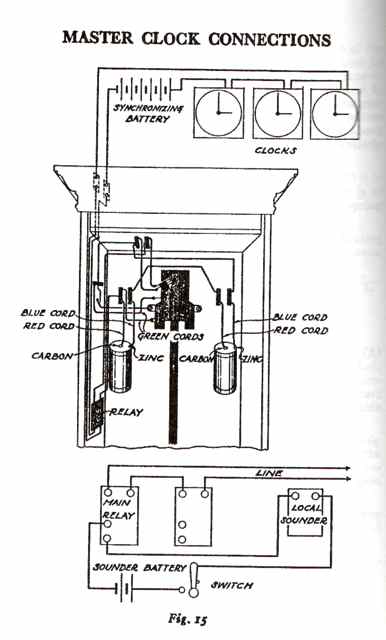

Tom, I don't have any, but have repaired a couple over the years. Here is the Western Union hook up for one of these and this has master clocks run timed from it. This diagram show it real well. I worked for the Northern Pacific for many years and the stations had these clocks that were set by Western Union. The guys compared their time and corrected as needed. Bill Carlson  | ||||

|

Tom, I should mention that the ones that I worked on had fairly good wiring. As in not brittle insulation and the clocks were metal, not wood. So they were probably newer than this one. If this doesn't have a motor, I'm curious as to what the clock is missing for parts to run it. I have a really large wooden one that is 40" tall by 17" wide. Its made by American Clock Co. It came from a railroad depot in Wa. Maybe Eddie can contribute some information too. He maybe more up to speed on these than I. Bill Carlson | ||||

|

| IHC Life Member Site Moderator |

Thanks Bill. I picked up two of the big wooden cases with the class intact & the Western Union metal plate on the front but unfortunately other than the mounting bracket in the back they were missing the movements. They still had the inspection cards in them from when they were serviced, I had planned on someday trying to find the movements to put in them but kind of let it slip away. Tom | |||

|

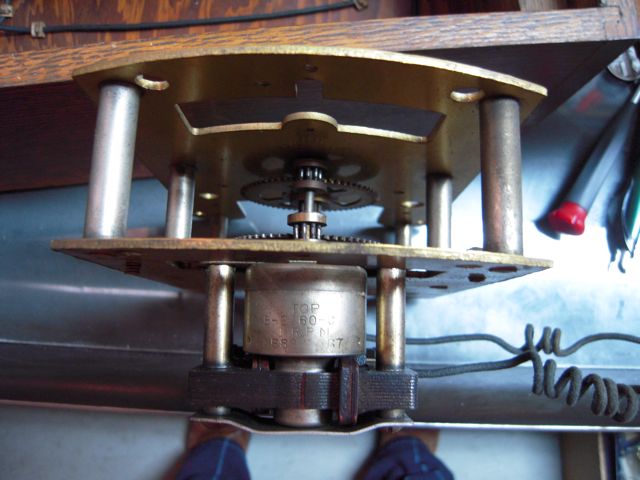

So I have discovered my clock is powered by a very old Telechron type B2 rotor and coil. I spent a good portion of yesterday looking for an expert Telechron rotor repair shop. The first shop wanted $120 plus shipping another wanted $75 plus shipping. Then I found one in my own back yard that trained with a Telechron expert and owns the factory equipment and drawings. Brien is the owner and charges $65 (including) return postage. Brien said the rotor will be rebuilt to factory specs. The turn around time will be 3 to 4 weeks.  | ||||

|

The top of the rotor.  | ||||

|

Top view.  | ||||

|

Top of rotor.  | ||||

|

Bottom of the rotor. Brien said the soot is very common and a dead giveaway that the rotor needs to be rebuilt.  | ||||

|

Front of rotor. He will remove the gear and then reattach it after the rebuild. The long bracket supports the front of the rotor to the movement.  | ||||

|

Back of the rotor. Brian said on the very old rotors like mine they were filled with oil in the back after being built/sealed. That is why you see the solder.  | ||||

|

I will be sending the rotor out tomorrow and will update you as this progresses. Mike | ||||

|

| IHC Life Member Site Moderator |

Mike Just curious, I can't read the voltage listed on the tag due to the glare. What does it say the voltage is? Great you found a guy their to do the work, I would like to see some photos when you get it fixed. Thanks for sharing. Tom | |||

|

| IHC Member 163 |

I, too, will be very interested in reading the final result on this rebuild. Regards! Mark | |||

|

I will keep you posted. Tom, The voltage is 110 on the tag. Mike | ||||

|

Bill, Great information. I think this rebuild is a fun lesson for all. Mike | ||||

|

I am getting ready to order a cord for the clock. Black  | ||||

|

Brown  | ||||

|

Twisted fabric cordset with antique style plug. What color do you think I should get? Mike | ||||

|

| Powered by Social Strata | Page 1 2 |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Very Old Wood Case Cincinnati Time Recorder

Very Old Wood Case Cincinnati Time Recorder

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Very Old Wood Case Cincinnati Time Recorder

Very Old Wood Case Cincinnati Time Recorder©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide