| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Hamilton presentation clock

Hamilton presentation clock

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Hamilton presentation clock

Hamilton presentation clockGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Greetings all. I'm new to the clock portion of this forum, so apologies if I'm asking silly questions! We just received a clock from my wife's grandfather tonight. It is a Hamilton that was presented to him for 40 years of service to his company. He received it back in the mid 80s. I'm just looking for information about it. Age is my first question. How common is it? As of now, it isn't running. I softly tested the attached key and there was no budging anything. Could it be overwound? Something else? At best, it would be nice to see if there is something simple to get it working again. Any information or comments is greatly appreciated. This is the first picture and a few others will follow. Thank you.  | |||

|

Picture 2. The front of the clock.  | ||||

|

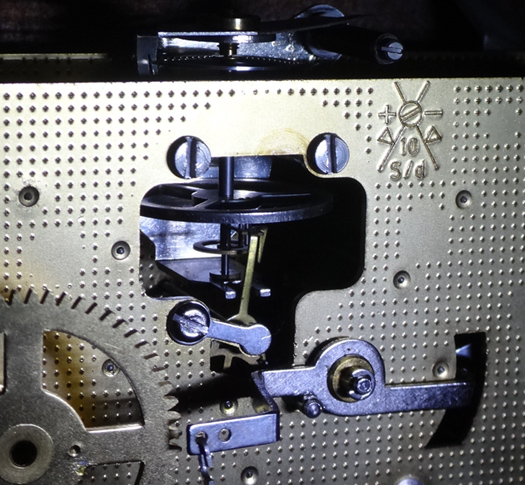

The inside back. It is a chime clock.  | ||||

|

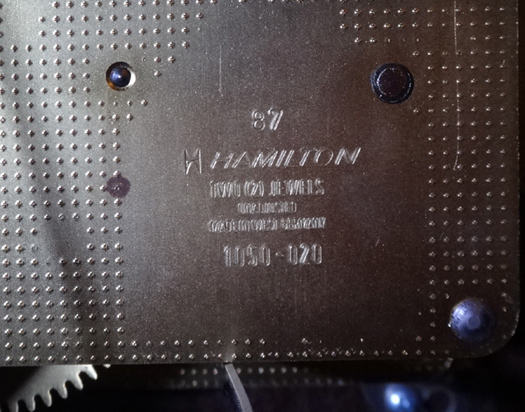

What info I can find on the surface with tearing it apart.  | ||||

|

Here is the last photo. Once again, any info is greatly appreciated.  | ||||

|

| IHC Member 1291 |

Looks like a vintage 70's-80's made in Germany for Hamilton Watch mantel clock called "The Wheatland" model. Here's the instructional manual that came with them; regards, bb | |||

|

Thanks Buster. Next step is to see if I can get it to work. If not, I've seen some inner workings online for $15 - $20. And since it isn't a major antique, I may just start playing with it! | ||||

|

Nice looking clock. The movement I believe was actually made by Hermle. These movements are fairly common and can be purchased new and/or used. I would imagine a good cleaning and lubrication would bring her back to life. Hard to tell without taking a look. Dave Turner | ||||

|

So how much trouble do you think I would cause if I tried to take it apart and look at it? Keeping in mind that I've never done something like that before! Since clocks are a larger than watches, should it be easier to play with or is this still something that a professional should look at? Thanks again for the input! | ||||

|

If you are inclined to try it, then I say go for it. Take a lot of pictures as you go, and pay particular attention to the striking mechanism/sequence. Take off a few parts, take a picture, etc. But first, before you do anything, be sure and let down the mainsprings!! Also, You said it appears to be wound tight. Try to let down the spring partially, then see if the clock will run before you go further. Dave Turner | ||||

|

I have a Hermle 340-020 which has 5 hammers and 1 chime. Yours looks to be a 1050-020 which has quite a few more hammers and chime options. I am NOT a clock expert but messed with a scrap 340-020 and will let you know what I can. There are three barrels (chimes, time, hour). You can see the holes in the front. To let down the mainsprings, you will have to take the movement out of the case / cabinet. To do this on mine, you have to unscrew the nut holding the minute hand on and then gently remove the hour hand. Turn the clock around so you are facing the back and Remove the screws (4-8) holding the movement and then you will have access to the front where you can let down the mainsprings. I used a helper to hold the movement, while I placed the key on one post and used a screw driver the release the "click" a few teeth at a time. There is ALOT of tension here. I mean if you let all of it go or try to let the spring drop down more than a few clicks at a time, something is going to break (finger vs metal....). Take your time, look up a few videos if you plan on doing this. It might need a cleaning, check the floating balance to make sure it works. These movements were buit super cheap and a lot of times it was more time and cost effective to just swap out the movement with a new one. Check the Bay of "e" to see if there are any working ones to be had for a decent price. If you don't want to buy a new movement You can also check all the pivots with the movement out and make sure nothing is gumming them up. Sometimes they just get old oil and dust and get stuck. Hope this helps. Dan Update:Mar 18... I made a few edits to what I typed as typing things late at night don't always make sense at 6am | ||||

|

I forgot to mention, I think that the "87" on the back of the movement indicated movement build year. So probably around 1987. | ||||

|

| IHC Member 1851 |

I did a complete takedown and clean on a very simular hermle recently. It was the same vintage and just gummed up. During the process I discovered the spring barrels can be removed without separating the plates. "You do not want the spring barrels exposed to solvent" unless you have the means to service them. So you could try soaking movement without disassembly (other than the barrels) in solvent scrubbing and agitating to degum and clean. As mentioned let down the springs first. Pull off the plastic gears on front and the plastic hammer drum for their preservation. Mark the barrels so they can be put back where they came from. To remove the spring barrels , take off the (3) retainers of click/ratchet wheels , the sub winding arbors are a keywayed shaft and should now slide straight out the front, the hollow main arbors are retained within the barrels. barrels can now slide out. | |||

|

Thanks for the comments gents! I haven't had any time to do anything with this clock except take the OK looking pictures above. Once I get a chance to play with it, I'll be keeping your instructions/thoughts VERY handy! And Dan, I knew what you meant by cheap. When I did the Google, lots of movements popped up for a very inexpensive price. Thanks again guys! | ||||

|

| IHC Member 1851 |

Soon after I had mine back together I was winding it and a click spring let go, they seem to be soft. Give them a little tweak at reassembly. | |||

|

I might add also, if you don't take the springs out of the barrels and clean both your not going to be very happy with the results. The gummed up springs in the barrels are usually the problem with these and also the floating balance can be a problem too. Good luck Bill Carlson | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide