| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Count Lever bounce S.T.- OG

Count Lever bounce S.T.- OG

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Count Lever bounce S.T.- OG

Count Lever bounce S.T.- OGGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

I picked up a Seth Thomas OG yesterday. I have found that the Governor fan was missing. After cleaning and inspecting It I found it to be in good condition. I have reassembled it and found that the count lever will not drop into the count wheel slot unless it is going pretty slow. This is when rolling the wheels with my fingers. I realize that the fan is missing and it controls the speed of the strike train. When rolling it slowly by hand it works great. My question. Is their susposed to be a spring on the arbor of the count lever arbor to help it engage the count wheel slot? Or am I missing something else? Thanks Bob | |||

|

By slot,do you mean the locking position on the countwheel Bob ? If you don't have a governor your warn pin on the locking wheel may not be able to engage the locking lever because of the accelerated motion.You may have to readjust your levers also.If your drop is not falling into the proper slot on the cam that also will impact the ability of the countwheel lever to function properly.Missing parts on any movement are always a bad sign.Put a new fly on your movement and then walk the strike side through it's sequences and correct as necessary.Leave the time train out.It doesn't sound like a major problem just a matter of synchronizing everything to work together.By the way,a helper spring is a matter of judgement.Sometimes they help the levers function better and sometimes they don't.Try it without the spring first and if you've done everything and it still misfires go ahead and add a spring. Let us know how you made out.. Respectfully,Bob Fullerton | ||||

|

Robert thanks for the reply. Yes I do mean the locking position on the count wheel. Sorry for not being more accurate with the terminology as I am still a rookie at this hobby. I agree with you that is usually is not a good sign when you see missing parts off a movement. But I did understand when I purchased them that I was buying as is. Also the taper pins were missing and the plates were held together with bits of copper wire. I tried to use a fan off of a New Haven movement and it still did not lock. This fan was about 3/4 inch shorter than a fan measured on a Gilbert OG so I assume it needs to be bigger. I have ordered an assortment of fans and hope one will be the proper size. If not I can probably make one out of some brass shim stock. It is frustrating having to wait on parts being a novice at this I have so few parts on hand. New or used. Thanks again. Grateful for the assistance Bob B | ||||

|

Don't feel bad Bob,the fella I mentored under wouldn't even let me put a store bought fan or lever in a clock.I had to make my own fans out of sheet copper for the experience.It kinda sucked at the time knowing i could buy a whole packet of assorted fans from Merritts but looking back in retrospect it was a great learning experience.I guess I only mention this to you just in case down the road you are missing a part don't be apprehensive about trying to fabricate your own.There is something to be said for fabricating your own parts,there's a lot of personal satisfaction to be had upon completion.Especially if the new part actually works properly. Bob,I'll give you some good advice,just take your time and be semi methodical in your diagnostic efforts.Believe me the most important skill you can have in clock repair is intuitive skills.Try to develop a feeling for when things just don't look right.If you can master that you'll be way ahead of the game. Best of luck in your clock repair endeavors,I'm sure you'll do just fine. Respectfully,Bob Fullerton | ||||

|

Bob, The count lever should be adjusted so that when it drops in the slot of the count wheel that the lever doesn't hit the bottom of the slot so hard that it bounces back out. You can make this adjustment by slightly bending the lever up. You should probably wait until you have the correct size fan to make the lever adjustment but if it still bounces when you are running it by hand then you've got nothing to lose by getting it in the ballpark now. Larry | ||||

|

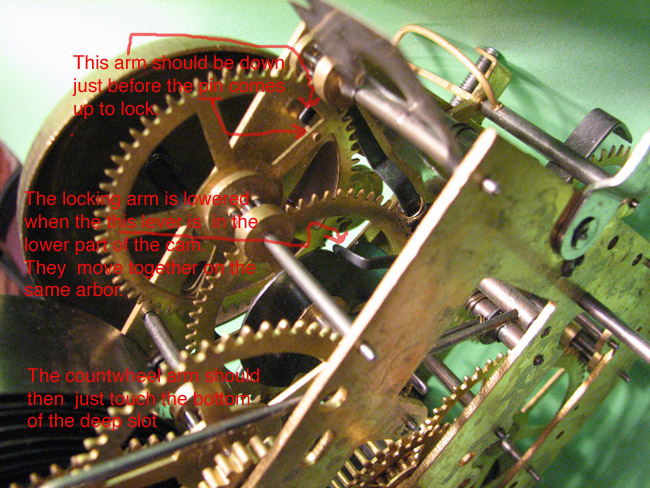

There are three elements on the same arbor in most of these movements. They move together. Be very careful when bending any of them, because bending one affects the position of the others. The key to locking is to make sure that the wheel with the cam is in sync with the wheel with the locking pin. The lever that rides on the cam should be just hitting the lowest part of the cam when the locking pin is approaching the locking lever. I have tried to explain with a picture.. hope this helps. If all that is in order, and it still doesn't lock, then look to see if someone previously has bent the wires. The arm in the countwheel should drop into the slots without touching either side of the slot. Often I have gotten a clock where the strike won't lock and the problem is that that lever was coming into contact with the side of the slot, so the locking arm ( they are on the same arbor and move in unison) could not drop far enough to lock. It is like detective work sometimes. check it over first. Bend as a last resort. Sometimes the helping spring is the last needed item. Tom  | ||||

|

Robert: I did fabricate my own fan out of brass shim stock and it works properly. It worked so good that I did not replaces it with one from the fan assortment I ordered. Each clock I work on is an adventure that I look forward to. So far I have learned from each movement I have worked on. Thanks for all the help. Bob B. Larry. Thanks for the tip on the count lever it seemed to be positioned just as you described so I left it alone. After installing the fan it helped. It still would miss (not have enough time to drop in the slot on the count wheel) I added a spring to assist in pulling the count lever down. Now the strike train works every time. I have had it on the test stand for two days. Thanks for your help. Bob B Tom: Thanks for the photo it helped a lot. Books and drawings are great but photos are the iceing on the cake! I was a bit off on the timing of the warning stop pin so a quick adjustment of the pinion took care of that. As I told Larry I added an assist spring to the count lever arbor and it works every time. I do have another question as to the weights. My Gilbert OG has weights that are equal in weight. This Seth Thomas has one weight that is about the same as my Gilbert OG the other weight is much heavier than the other weight? I am not sure if the weights are the proper weights that should be on this clock? Do the weights vary as to the movement makers? All my OG's are 30 hour movements. Thanks for all your help Tom. Bob B | ||||

|

When I don't have the original weights with a clock, and am not sure what size to get, I hang a small container from the hook the weight would go on. Ataching three strings or wires from the rim of the container will allow it to hand straight and not tip an an unfortunate time. I have one of thoe frozen juice concentrate cans, but that probably dates me. Then I add lead shot until the clock runs. I then weigh the container and know what weight weight to order. Tom | ||||

|

Another method for determining the weight needed to run a clock is as follows. I have heard of this but never tried it. Secure a fish scale (for weighing your catch) to the bottom of the case and tie the cord from the winding drum to the top of the scale, give a few turns to the key to wind the cord on the drum and put some tension on the scale. Start the clock running and when it stops check the scale for the weight. The weight required to run the clock should be a few ounces more than the scale registers--so I have read anyhoo. | ||||

|

Tom: That was the approach I was thinking about. I was wondering where to get the lead shot? Don't know any reloaders (shotgun shells)who use lead shot any more.I could get steel shot instead. John: Good Idea. I may play around with that a bit and compare it with the results from adding weights into an empty cup as Tom suggested. Thanks guys. Always get great advice on this forum. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide