| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  All Wristwatches Discussion Forum

All Wristwatches Discussion Forum  Accutron 218

Accutron 218

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  All Wristwatches Discussion Forum

All Wristwatches Discussion Forum  Accutron 218

Accutron 218Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

I have a Accutron 218 that runs about 1-2 minutes fast per day. It ran at that rate for two months and the battery quit. I replaced the battery and it is still keeping the same rate. Any suggestions? My 214 keeps time to 1 minute per month and I would have figured this one to do better as it is in far better condition than the 214. Thanks, Aaron | |||

|

| Watch Repair Expert |

Sounds as though the movement might be slightly out of phase..... Also sounds as though the first battery you had might have spent a long time sitting on a shelf before you finally bought it. If you bought the second battery from the same place, it may produce similar results. ============= Steve Maddox Past President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

Sorry Steve I should have been more clear. The battery that only ran two months was in the watch long before I got it. I was only timing it for the two months. The only reason I mentioned the old battery was to be sure thet everyone knew the problem existed with both the old and the new battery. Thanks, and how do you correct the problem you mentioned? Aaron | ||||

|

| IHC President Life Member |

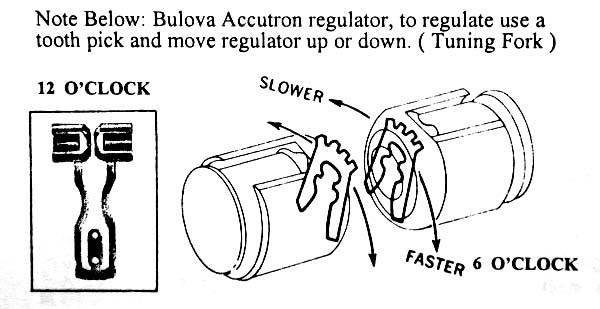

Aaron, I've worn Accutrons daily for thirty-plus years and found that unless they are erratic which yours is not they can be adjusted to near perfection. Your 214 is within the factory specs "a minute a month" and I'll bet the 218 will soon be again as well. It probably got slammed hard in shipment. The "phasing" Steve spoke of is beyond my capabilities but regulating an Accutron movement is a fairly simple adjustment. Regulation involves a special Accutron-related tool but a toothpick will do if you are very, very careful. Do an "Accutron" search on IHC185 for further worthwhile information. Lots of good Accutron info is located on the internet and a "Google-Search" of "Accutron" would easily yield additional results. The drawing below is from "The Complete Guide to Watches" and has the basic information you need. Proceed with caution and move both sides toward you an equal amount. A lot of wierd things happen in shipping so lightly "puff" the fork area to be sure there is no dust or debris in the way. Steve knows far more about these than I do and any further recommendation he makes should take precedence over my suggestions. This may help get you going, Lindell  | |||

|

| Watch Repair Expert |

Aaron, The information provided above by Lindell accurately pertains to "regulating" an Accutron, not "phasing," which is a different thing. The total range of adjustment through the regulator system is plus or minus about 30 seconds per day, which is not sufficient to rectify a 1 - 2 minute per day problem. Basically, the way an Accutron works is that the tuning fork is magnetically "pinged" into oscillation by the electronic circuit and coils. The frequency of the "ping" isn't critical, so long as the fork continues to oscillate. Think of it like ringing a bell; it doesn't matter if you ring a bell fast, or slow, the tone produced by the bell will remain unchanged because the bell is tuned that way. The same is true of the tuning fork in an Accutron; regardless if it's pinged fast or slow, the oscillation frequency of the fork will remain constant. In order to "transfer" the mechanical motion of the vibrating fork into a force with which to drive the movement, the tuning fork has a tiny leaf spring mounted on one side. That spring is called a "pawl," and its unattached end is fitted with a jewel (much like a pallet stone), which is supposed to engage an "index wheel" with 300 "saw-tooth" shaped teeth around the perimeter. When the tuning fork oscillates away from the index wheel, the pawl "ratchets" backward over two index wheel teeth, and when the fork oscillates the other way, the jewel on the tip of the pawl engages the teeth on the index wheel, and advances the wheel forward. For every complete oscillation of the tuning fork (from one extreme of motion to the other and back again), the tuning fork is supposed to advance exactly two index wheel teeth, no more and no less. Now, here's where the fly enters the ointment: The original batteries for Accutrons were mercury cells, which produced 1.35 volts. Unfortunately, those were banned by the EPA, and only silver oxide replacement cells, which produce 1.55 volts, are now available. The extra voltage applied to the coils causes the tuning fork motion to be greater than it would be with 1.35 volts, and unless the index system is adjusted perfectly, the extra motion can occasionally cause three teeth to be advanced in an oscillation, instead of the usual two. Obviously, that will make the watch produce a gaining rate, the amount of which is directly related to the degree of phase error. It's possible to phase most Accutrons to operate correctly with 1.55 volt batteries, but the "pawls" have to be adjusted almost perfectly. As noted above, the "index pawl" is attached to the tuning fork, but another pawl (called the "ratchet pawl") is attached to a stationary post, in order to prevent the index wheel from rotating backwards. In the following sketches, the index pawls and a section of the index wheels from a typical Accutron movement are represented. In figure "A," the "normal" amplitude of tuning fork oscillations produced by a 1.35 volt battery is illustrated. Note that over the entire range of amplitude, only two index wheel teeth are covered. In figure "B," the increased amplitude resulting from a 1.55+ volt battery is represented. Amplitude of that amount allows three index wheel teeth to be covered by the range of motion, and depending on how the ratchet pawl is adjusted, it's possible for all three of those teeth to be advanced, rather than the usual two. Figure "C" illustrates how careful adjustment of the "phasing" (the relative positions of the index and ratchet pawls) can render excessive amplitude harmless in most, if not all cases. Even though the fork will still take excessive motion with a 1.55 volt battery, by adjusting the ratchet pawl (not shown), the resting position of the teeth on the index wheel can be adjusted so that only two teeth are advanced per oscillation, even with the increased motion. In essence, THAT is "phasing." =================== SM | |||

|

| IHC President Life Member |

Another day, another something new to learn! Thanks Steve, how involved is it to correctly set the ratchet pawl adjustment? One more point, I recall that Bulova tested every Accutron over a range of voltages peaking at 1.75 volts without error before leaving the factory. I have been using the modern 1.55 volt batteries for several years now with no problems. Perhaps I have been fortunate to have better than average condition movements or I am just plain lucky in that regard. Anyhow, I can tell you, I really do enjoy my Accutron watches! | |||

|

OK, now another question. Who is the Accutron Man to fix this problem? Aaron | ||||

|

| Watch Repair Expert |

I do work on Accutrons, but I'm starting to like them less and less......... Of course, as with anything else, having the right tools for the job makes it infinitely easier. First are the good service manuals that were provided by Bulova for the various models. Those are really essential in learning the operating principles, as well as many useful "tricks." Next, it pays to have an Accutron test kit, and an M-80 Vibrograph. With all that, plus some knowledge and experience, the only real problem is spare parts, and needless to say, those are becoming an increasingly more significant problem as the years go by. As a case in point, I have an Accutron 218 "Spaceview" in my shop right now that belongs to a customer in NC. It was sent to me by a watchmaker there who was so intimidated by it that he wouldn't even remove the rear cover. Upon initial inspection, I found that a movement screw had vibrated loose, and was stuck to one of the magnets on the tuning fork, obviously preventing it from vibrating. I removed the screw, replaced it into its proper location, and the movement started running fine. I should have stopped at that point, but I didn't. The case and expansion band were absolutely filthy, and the crystal was so scratched that I could barely see through it. I decided the customer would surely feel better about the repair if the watch was returned in better cosmetic condition, and I therefore polished the crystal and case, then removed the crystal so that the case and band could be cleaned in the ultrasonic cleaner. "Spaceview" models do not have conventional dials. Instead, the "Accutron" name and numerical index are reverse-painted on the inside of the crystal. Needless to say, cleaning such a crystal on the inside will remove the print, and I knew that, which is the reason I removed it before cleaning the case. Unfortunately, when I attempted to reinstall the crystal, I discovered that the plastic from which it was made was significantly degraded, and it cracked almost exactly in half. That's the point at which the situation remains right now. I haven't been successful in my attempts to get a correct replacement "Spaceview" crystal, and to be perfectly honest, I really don't know what to do. The only thing I know for sure is that's just another reason that I'm becoming increasingly less enthusiastic about working on Accutrons. ================= SM [This message was edited by Steve Maddox on March 13, 2004 at 7:19.] | |||

|

| Watch Repair Expert |

By the way............. Do not demagnetize an Accutron, or any other type of electric watch! Although the operating principles differ, on a very fundamental level, all electric watches convert electrical power into mechanical force (to operate the gears, etc.) by means of permanent magnets. Needless to say, if the magnets lose their strength, that's the end of the line for the movement. Most ordinary watch demagnetizers are not powerful enough to demagnetize strong permanent magnets, such as those typically used in watches, but I suspect that repeated attempts with a "pulse-type" demagnetizer (which are supposed to be 20 to 50 times more powerful than conventional "solenoid-type" demagnetizers), might well have a cumulative adverse effect. As a curious note, I once repaired an Accutron 214 that had somehow been passed through an MRI machine. I have no idea how strong the fields are in an MRI, but the magnets in the Accutron's tuning fork were absolutely dead, and the entire fork had to be replaced in order to return the watch to operating condition. ====================== SM | |||

|

here are a couple of links i had bookmarked for future use..... pretty certain Steve may know about them, but thought it may help anyway http://www.accutronwatches.com.futuresite.register.com/? http://members.iinet.net.au/~fotoplot/acc.htm | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide