| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  It won't wind up!

It won't wind up!

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  It won't wind up!

It won't wind up!Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

I got an interesting email from an NAWCC member posing an interesting problem. The problem was, after this person replaced a cable on a Sligh grandfather clock, he could only wind the clock 6" from the bottom of the case. (We have solved the problem.) The cable was installed correctly on the drum. The cable was the right length. Would anyone care to guess how this situation could exist? Tom | |||

|

Was something put on backwards? Like when I reassembled my Seth Thomas Adamantine movement, it struck the wrong time, 12 at 1:00, 11 at 2:00, 10 at 3:00, etc. I had put the count wheel in backwards. Andy | ||||

|

Andy, Yes! Those nasty countwheels. I've been there. No! Not the solution this time. He could successfully wind the weight from the bottom of the case to about 6" above the bottom. Tom | ||||

|

Tom, Your friend had the stop works out of phase with the cable. Some times, when the stop works is installed improperly, the clock will only allow 6-8 iches of the cable to play out after being wound. I have had clocks brought to me with this problem fresh from another repair place. Best Regards, Dick Feldman | ||||

|

Dick is absolutely right. Geneva stops, used on a few of the older models of American shelf and hanging clocks, was brought back for the newer grandfathers. This one stumped me for a while. Back when I did a lot of work on grandfathers, they weren't using the geneva stops. When the cable was installed, the position of the stops was not taken into consideration. I "solved" the problem (knowing where to get an answer is a major problem solving strategy) by asking my friend Norm (clock shop owner). It took him all of a half second to tell me what the problem was. Tom | ||||

|

Good evening: Good evening: I ran into a similar problem with my 15 day ST World. I knew the stop works needed to be set properly; however due to the fact that I didn't really study them on disassembly; it took a few tries to get them set correctly. The stop works are a great idea! gp Grant Perry | ||||

|

Grant, Seth Thomas used geneva stops more than others. What is common, is to find that a "repairman" of the past has disabled or discarded the geneva stops. Very common to not see them on a movement that should have them. Tom | ||||

|

Maybe they were discarded by someone who could not figure out how to reset them on reassembly? I guess you could also get more power from the springs with the stops off or disabled... Grant Perry | ||||

|

Grant, I believe your first coment is correct. They just didn't know how to set them, and unlike you, did not take the time to figure it out. The "more power" theory sounds good, but the stops were designed to keep the timekeeping in the ideal range of the spring for most accurate timekeeping. It is interesting to see them brought back for the newer models. The Seth Thomas clock in the For Sale section has a good picture of geneva stops. Tom | ||||

|

Although Geneva stops and Stop works function the same, the purpose is not. Stop works on a cable driven clock is designed to prevent two conditions. One purpose is to prevent the cable from unhooking from the cable drum on the low end. Hopefully the travel of the weights is limited by the floor of the clock case. I have, however, seen cable driven movements used in Gallery clocks, which have no floor. The other function is to prevent the drum from accepting any cable when full. If cable is allowed to double up on the drum, there is a good chance it will foul and tangle. Since cable driven clocks have almost even power supplied throughout the run cycle, there is no advantage to eliminate the first and last part of the cycle. With spring driven clocks having Geneva stops, the idea was to “stop out” periods with higher and lower power, hoping to get a more consistent power supply to the movement. | ||||

|

Dick, ABSOLUTELY RIGHT!! Well said, I was using the geneva stops and stopworks interchangeably and that is not accurate. You explained them very well. Thanks! Tom | ||||

|

Thank you for the additional info Dick. That is what I LOVE about this hobby. I can learn new things every day. Thanks to you and Tom for the lesson! gp Grant Perry | ||||

|

Tom could you point out the Geneva stops on the spring driven Seth, that you have up for sale.I am not sure where to look for them, besides in the mainspring area. Thanks Tom, interseting thread and thanks also to Dick. | ||||

|

Dick, Does Herschede use the stop works on their cable drive movements? I noticed a shorter model in a funeral home, and I believe the weights will go all the way to the bottom of the case. A Christopher Columbus model is nearly a foot taller, which I thought meant it would run longer than the shorter clock. The weights will stop about a foot before hitting the bottom. Apparently the movement is set up identical no matter how tall the case is, it still runs the same length of time. Andy So many clocks, so little time. | ||||

|

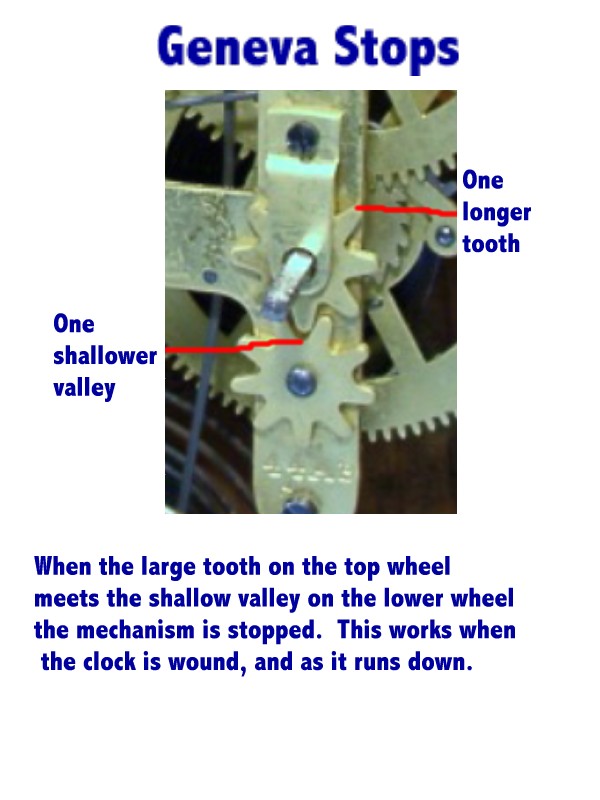

AS requested, here is a close up of the Geneva Stops on a Seth Thomas clock. There are variations of this design. Tom  | ||||

|

Andy, I think all of the modern cable clocks have stop works. I have noticed that the top and bottom settings on them are pretty much the same, regardless of the case length. Consequently, even in a tall case, the weights can rest on the case floor without the stops being set. I have never worked on a Herschede, so I cannot say on that. Stop works can be a real pain as the indexing marks on the gears usually are supposed to be aligned with the cable played out. Making the three weights stop at the same position when the clock is fully wound can be a real challenge as one tooth difference is noticeable. The gear that fits on the winding arbor has a choice of four positions because it has a square hole. The other gear free wheels on a post. The two will not normally mesh in the “locked” position but have to be lead into that position a couple of teeth ahead of lock. I usually set the stop with one loop of cable on the drum when locked on the bottom end. While this coordination is all going on, the loose ends of the cable are usually catching on one’s shoes or tangling around some tools or something. In my book, they could have done a better job with design. I suppose if a guy sat in a factory all day and set the stops on clocks, it would be “duck soup,” but it seems the length of time between me setting stops is just enough to forget the finer points. Evidently I am not the only one to be frustrated by stop works as I have seen a few clocks come in with the gears missing. It gets to be kind of the question about where does the rubber from tires go when they wear. Somewhere there must be a coffee can full of stop works gears. I don't have one in my shop now or I would send a picture of the mechanism. Till then I hope you enjoy the picture of Lake City Colorado Best Regards, Dick Feldman  | ||||

|

Thanks Tom for the explanation and picture, it makes sense since i can see it.Good idea also to have these on clocks. Dick that is a nice picture, when did you take it? The mountains are beautiful and the trees. | ||||

|

Here are a couple of pictures of the stops in a Sligh cable wind grandfather clock. The arbor is wound clockwise and has stopped and dropped back a bit to the closest click position. Tom  | ||||

|

This shows the three winding arbors and their stops. Tom  | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide