| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Shellac

Shellac

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Shellac

ShellacGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

When cementing a roller jewel, or pallet jewel with shellac, how long should the shellac be left to harden before putting the jewel in -service. Is there any set time. Frank | |||

|

Frank, The nice thing about shellac is just how quick it sets... as long as it takes to cool. With the small parts we are dealing with is almost instantaneous. The secret in getting shellac to be a good bonding agent is getting all parts clean and free of any oils, dirt etc. | ||||

|

Mike Thanks for the information. I just replaced my first roller jewel, and wasn't sure how long I had to wait before putting the roller back in service. Frank | ||||

|

Congrats on your first roller jewel replacement Frank. Let us know how the watch comes out. Brian C. | ||||

|

Frank, was the roller replacement job a very dificult one, those roller jewels can be pretty small to see and to get hold of? | ||||

|

Replacing roller jewels to me is an "Art"...The biggest problem I have is figuring out the sizes. Diameter, length, round, half round. Is there a chart or something that tells what fits what..For American 18 size pockets just how many "sizes" are there ???? John Pavlik | ||||

|

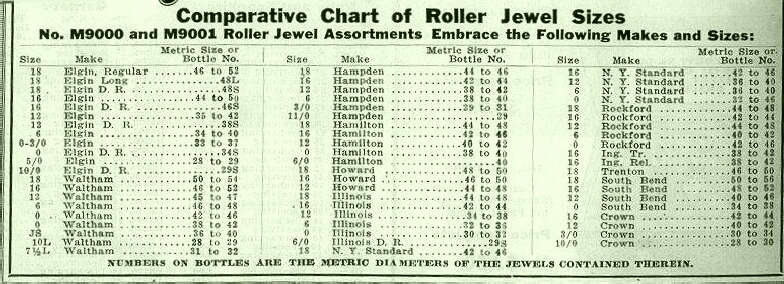

John, I usually just go hy hole size in roller. This is not proper procedure but is right most of the time. If it`s wrong I have to redo it. You are supposed to use a roller jewel gauge. Find the finger that just fits into the fork. The size on this finger is proper roller jewel diameter. Then choose the correct jewel (round, half round, etc.) with that diameter. The chart below may help you. Kenny  | ||||

|

Brian The watch was a good patient, and came thru the procedure with flying colors. It's now happily ticking away the hours. Kevin The replacement of the roller jewel wasn't too difficult, as I had the right tools on hand.I have a pair of tweezers,just made for the job. They where purchased from Dashto. They have a groove on the ends that securely hold the jewel while you position it in place. I first tried it with my regular tipped tweezers, and I couldn't really handle it. The part of the job that I was really concerned with was not to overheat the shellac. John I gauged the size of the jewel by using a roller jewel gauge, as I could not locate the original one. That was also purchased at Dashto's site. Frank | ||||

|

Kenny, Thanks for the chart.. do you understand what the purpose of the different diameters serve. Sometimes it appears that there are 5 thousands different for the same model watch..??? A wider fork opening on the same model, accomplihes what??? John | ||||

|

Frank, A tip on holding the roller jewel on the tweezers. I touch my tongue with finger then apply just a small amount of saliva to the tip of the tweezers. This will hold the roller jewel onto the end of the tweezers. A trick taught to me by my watchmaker buddy. Tom | ||||

|

Hi Tom Thanks for that tip. I also read that somewhere, but never tried it. Next time. Hey Tom, the next time I'm out your neck of the woods, you will have to introduce me to your buddy, and I won't forget to come bearing gifts, I owe you. Frank | ||||

|

quote: Kenny | ||||

|

Kenny, I get it now... I have a Waltham model 83 with the "RARE" #54 roller jewel not he "COMMON" #52... John | ||||

|

Hi Frank, Give me a hollar and come on out. I'll take you watch scrounging the western PA way. Tom | ||||

|

Tom Thanks for the invite. The next time I'm headed out to western Maryland to visit my brother-in-law,I will give you a call and swing-by,for a visit. Frank | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide