| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  B5 watchmaker roller tabel remover set

B5 watchmaker roller tabel remover set

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  B5 watchmaker roller tabel remover set

B5 watchmaker roller tabel remover setGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

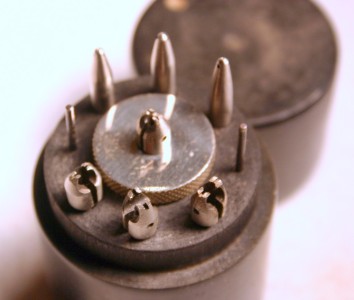

Is there anyone knowing/using this tool? On the back of central part I read H.C.WILSON ELGIN ILL. I found and bought it on Ebay. Thank you. Bulent Ogel  | |||

|

| IHC Life Member Site Moderator |

Hi Bulent That is a handy tool to have, it is a roller table remover set. I have the same set Tom | |||

|

| IHC Life Member |

I use the set I have to remove the roller table before taking the staff off the balance wheel. Mark the edge of the balance wheel before removal so you can put the roller jewel back in the same place. | |||

|

Thank you Tom. Thank you Roger. Bulent | ||||

|

| IHC Life Member Site Moderator |

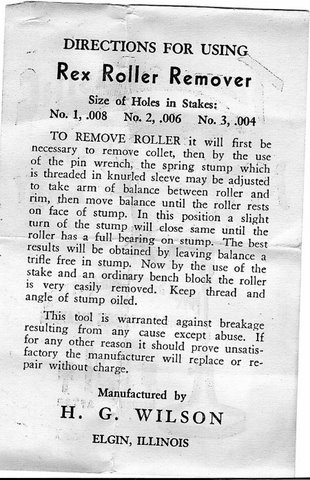

Bulent Not sure how well this will show in the photos but I remembered mine came with the box & instruction. Tom  | |||

|

| IHC Member 376 Watchmaker |

Bulent i can post some pictures of how this is uesd if you need some pictures,,I like pictures myself,,I have a set of these and use them a lot. | |||

|

Thank you very much Samie. My e-mail is bulent.ogel@gmail.com Bulent | ||||

|

| IHC Member 376 Watchmaker |

Bulent i will take some pictures in the morning and email them too you.. | |||

|

Just discovered this wonderful thread. May I have those pictures as well? I am in the process of taking that first step in balance staff removal. Thank you! k_morford@hotmail.com | ||||

|

| IHC Member 376 Watchmaker |

Kenneth i will take some pictures later today showing how too use the roller remover i did not save the pictures i took before.I think this is one of the best tools for removing roller tables i have ever used. | |||

|

| IHC Member 376 Watchmaker |

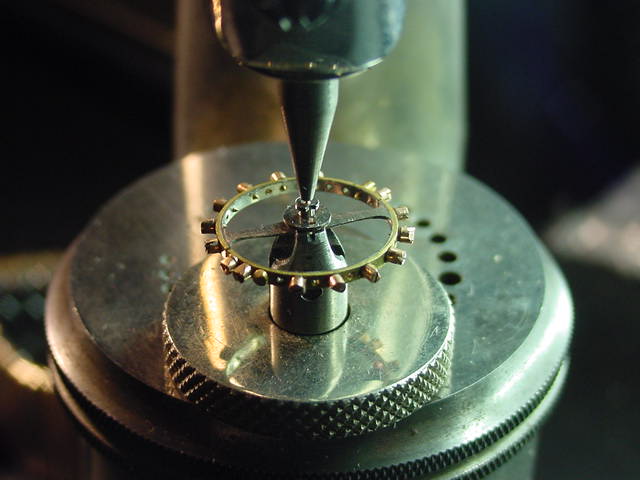

Kenneth the remover i use is a rex and they are very easy too use.. Frist put the remover in your anvil you will notice there is a small hole for lossen or tightening the jaws on the table ,you want it loose enough where the balance can drop down after the roller table comes off.Also noitce the groove in the roller remover it is where the roller jewel sets so you won,t knock it loose when removing the large roller table..  | |||

|

| IHC Member 376 Watchmaker |

Here is a waltham balance outof my junk box ,,After you remove the hairspring place the balance in the remover and choice a round nose tapered stake just big enough too go over pivot on the staff,,don,t use a flat end stake ..Notice the roller jewel is setting in the groove  | |||

|

| IHC Member 376 Watchmaker |

Then with a few light taps on the stake with a small hard rubber or rawhide hammer the balance will drop down and leave the roller tables setting on top of the remover..When you do this have your anvil setting back on the bench away from the edge beasuse these will fall off sometimes.What i do is leave the stake setting against the roller tables till i get ahold of them with a pair of tweezers.. Don,t go at this like you are driving nails or you will damange something..  | |||

|

| IHC Member 376 Watchmaker |

Maybe you already know but if not here is a picture of the type stake you use too drive the large roller table back on the staff..They have agroove in the side again for protecting the roller jewel. Hope you can make sense or understand what too do i am not the best hand at describing something but maybe it helps..  | |||

|

Samie, That's a great demonstration. I've got one of these sets and have been wondering if I was using it correctly. I'm glad you posted it for everyone. Together with the info from Tom and Roger it's a great lesson. Thanks, RR | ||||

|

Thank you Samie for the great demonstration! I benefit most from such great pictures wonderful pictures and post! Thank you so much. ONce the roller table is off, does the staff follow in an easy manner? I have a few watches with the same behavior-running fine until I stand them up; or they run well only on their face or back.. I am convinced this is a staff issue. Is the most common problem a worn jewel or a worn pivot on the staff? | ||||

|

| IHC Life Member |

Kenneth, Replacing a staff is a lot more involved than taking off a roller table, unless it happens to be a newer watch with a friction staff. Diagnosing the problem is the first step in fixing it. There can be a multitude of reasons why a watch will run well in one position, but not in another. Cracked or broken balance jewels are very common, as are bent or worn pivots. These problems are easily seen under magnification. Isolation is an excellent diagnostic method that will help determine where a problem may lie. If you feel you have a balance issue, you can let down the mainspring, remove the balance cock and balance assembly, then take the pallet cock/bridge off and remove the pallet. Replace the balance cock and balance assembly and give the watch a twist of your wrist to set the balance in motion. You can pick up the watch and turn it to various positions while you watch the balance to make sure it spins nicely in all positions. I have a rule of thumb that a balance should spin back and forth on the hairspring for at least one full minute and come to a gradual stop without any jerking action. It is a good idea to make sure that all the balance screws are present and none are loose. When the balance is at rest, check to see that the roller jewel has stopped in the middle of the banking pins when looking in a straight line from the pallet jewel hole. This will make sure the watch is in 'beat'. If it isn't lined up, the hairspring is turned on the staff to make the adjustment. While the pallet is out, give the watch a slight wind and watch the escape wheel for good train motion. What you would like to see is the escape wheel spin smoothly and actually reverse direction when it completely unwinds. This shows that the mainspring has totally unwound and recoiled a bit and the escape wheel turning backwards reflects this. If staff replacement is in fact needed, my feeling is the only right way for a non friction staff is to cut the rivet on the lathe so it pushes out easily. Driving it out with a staking set, in my opinion, distorts the balance hole and each staff replacement done by driving it out makes the distortion worse and worse and you will never have a true balance again. Reinstalling a new balance staff involves 'staking' or riveting the staff to the balance wheel and then going thru a poising operation which is balancing the balance wheel. You may have to vibrate the balance in order to have it run at the correct 18,000 beats per hour. This post sure became much longer than I anticipated, but the bottom line is once you get as deep into repair work as staff replacement, you have to be aware of all the ramifications of what you are doing, you must have the skill to do the work, the tools to do the work and certainly a lot of patience. Roger | |||

|

Thank you Roger so much for the information. Please do not apologize for the response; in my opinion when it comes to watch repair there is no such thing as too much depth of information. I am always looking for just this kind of information which you have so graciously provided, because this kind of thing is not available in book form. At this stage of my skill I have yet to replace a staff, and I am in need of many of the basic tools such as the rollor table removal set. Ken | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  B5 watchmaker roller tabel remover set

B5 watchmaker roller tabel remover set

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  B5 watchmaker roller tabel remover set

B5 watchmaker roller tabel remover set©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide