| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  When a serviced Double Roller overbanks!

When a serviced Double Roller overbanks!

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  When a serviced Double Roller overbanks!

When a serviced Double Roller overbanks!Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

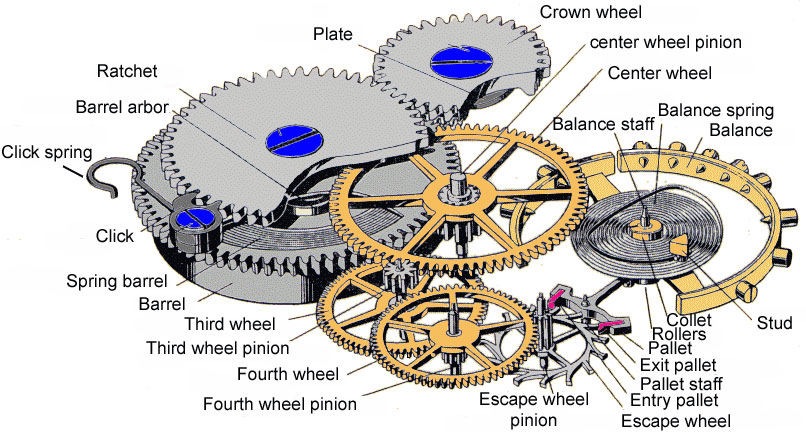

A friend came to the shop and showed me his nice recently serviced Hamilton double roller 992 with one "problem", it OVERBANKS!!!! Double rollers are designed to prevent overbanking . . . all the time! Here is a typical D.R. Movement;  | ||

|

| IHC Life Member |

After a careful check, I found the problem. The Pallet fork bridge had not fully seated down to the dial plate. This allowed the very short pivoted (21+ jewel stuff only) pallet fork pivots to "fall out" of their pivots far enough that the pallet fork (as I discovered) was actually flopping up and down enough in the pivot jewels to let the safety pin MISS THE SAFETY ROLLER COMPLETELY! INSTANT OVERBANK! This is easy to fix (carefully). Remove the Balance wheel and Balance cock assembly, let down the mainspring and re-seat the pallet fork bridge to the dial plate making sure it leaves only a small end-play for the pallet fork. Note: this is less likely to happen with most 19 (and fewer) jewel double roller watches because they have a nice long pivot on the Pallet staff that does not use cap jewels to control end-play, so no "flop" | |||

|

So, in the described situation the pallet fork (pf) was traveling Vertical and horizontal due to the two(2) screws on the Pallet Fork Bridge being loose. Besides overbanking was there any damage to the pinion itself or the upper/lower jewels? What is the best way to ensure the "ideal" tighten on those screws besides going to the extreme of taking some or all of the snap out of the PF? | ||||

|

| IHC Life Member |

There was no damage to the Pallet Fork pivots mainly because the watch quit running almost immediately each time the position was changed. The bridge dowels were very tight which had evidently "fooled" the last service person to- think the bridge had "bottomed out" when it was still left "up in the air". Too often watch plates and bridge dowels are very tight. In a service, I pre-test the assembly of these and loosen them up if needed before endangering the pivots which can easily be damaged if a "too tight" bridge or plates "snaps" down when the pivot decides to "shift" a little. | |||

|

| IHC Life Member |

David Do you broach the hole. Which make more sense. Or do you remove the bridge dowels with a pin vise then turn them down a smidgen. | |||

|

| IHC Life Member |

I either burnish or broach the pin holes until the parts fit without forcing the fit. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  When a serviced Double Roller overbanks!

When a serviced Double Roller overbanks!

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  When a serviced Double Roller overbanks!

When a serviced Double Roller overbanks!©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide