| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Hamilton 972

Hamilton 972

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Hamilton 972

Hamilton 972Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Member 1610 |

Take a look at my Hamilton 972. It is running face up and with the bail up but stops face down. I still need to clean it. This was really a project to put together my 972 to see if it would run and to attempt to make a winding stem. Thanks to Dan Carter and Jared Brinker for providing me with some photos of the old special winding stems these old Hamilton's used I was able to make one. The stem I made works fine. After making the winding stem I needed to replace the mainspring. After changing the mainspring I noticed a tooth missing on the winding wheel so I replaced it with a winding wheel off a 975. So if any of you good people here have a winding wheel that matches I will be more than happy to take it off your hands. (Got one from Edward Kitner)Thanks Ed. There will be a picture showing the pattern later. Not wanting to mess up a good case I put together this case from parts and polished it. The case had one crystal that was very scratched up so I polished the scratches out. The other side needed a crystal and the only one I had to fit was scratched up so I glued it in and polished it. So this IS NOT a salesman case. I did not have any hands for it but I had some new "Favorite" brand hands made for a 16s Hamilton so I put them on. I did clean the dial to make it look better. I know that a lot of people will not like the fact that this watch is just pieced together. I will be exchanging parts as I get them to make this correct. REMEMBER this was an experiment to see if I could make a stem on my lathe so I still have a lot of work to do but I am very happy with the results so far. | ||

|

| IHC Member 1610 |

Picture of the movement as I got it.  | |||

|

| IHC Member 1610 |

Picture of the back as I got it.  | |||

|

| IHC Member 1610 |

Scrap parts that I put together to make the watch. NOTE the stem I will cut down later.  | |||

|

| IHC Member 1610 |

Close up of stem before cutting.  | |||

|

| IHC Member 1610 |

Close up of stem after cutting and it works perfectly.  | |||

|

| IHC Member 1610 |

Finished front view.  | |||

|

| IHC Member 1610 |

Finished rear view.  | |||

|

| IHC Member 1610 |

Front without bezel.  | |||

|

| IHC Member 1610 |

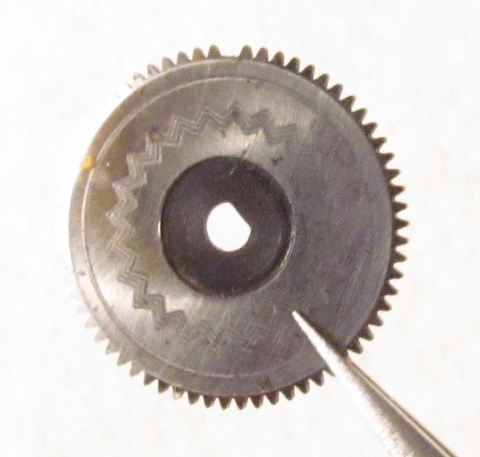

Rear without bezel. Notice the winding gear from a 975 does not match. I hope one of you have a correct one for me.  | |||

|

| IHC Member 1610 |

Winding gear showing broken tooth. I sure hope one of you fine people have a gear that matches his pattern so I can make this watch complete. (Got one from Edward Kitner).  | |||

|

Harry I applaud your accomplishment. You resurected a Hamilton watch from the parts bin. Nice job on the stem. I needed one and was lucky enough to have a friend that had an extra one. Now I get to help you, I have a ratchet wheel that matches your crown wheel. Send me your address. | ||||

|

| IHC Member 1610 |

Bless you Ed. So the big wheel is called the ratchet wheel and not the winding wheel.What is the small wheel called. My book just calls them both winding wheels. (Never mind I see your post it is called the Crown wheel) I'm glad you got your staff. I could not find one so my first project with my new old lathe was to try my had at the stem. Here is my address and please let me know how much money to send you. Harry J.Hyaduck Sr. 2010 Brook Valley Ct. Jonesboro, Ga. 30236 Thanks a million! | |||

|

| IHC Member 1357 |

Great job Harry!! Roger | |||

|

| IHC Member 1610 |

Thank you Roger. | |||

|

Harry, Just pass it forward! | ||||

|

| IHC Member 1610 |

Thank you Ed I will certainly do that. | |||

|

| IHC Member 1610 |

Thank you Ed the ratchet wheel arrived today. It is very nice. Thanks again. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide