| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  how to remove a pinion from 4th wheel

how to remove a pinion from 4th wheel

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  how to remove a pinion from 4th wheel

how to remove a pinion from 4th wheelGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Hi, I am very new to watchmaking but am getting the hang of it, and loving it I might add. I am working on an Elgin movement grade 290. I had the thing going until it hit a broken tooth in the 4th wheel. I managed to get a wheel that is in perfect shape, except that the last person that worked with the part put the wrong length pinion in and put it in wrong. So what I would need to do is get the wrong pinion out of the good wheel, and get the good pinion out of the broken wheel. I have a staking set and the basic set of tools, but have no idea if this is do-able with what I have, if I need another of the millions of tools you can use, or if I should just find another 4th wheel. I don't mind the challenge, so if it's fixable, that would be my preference. Thanks for any help offered. | |||

|

| IHC Life Member |

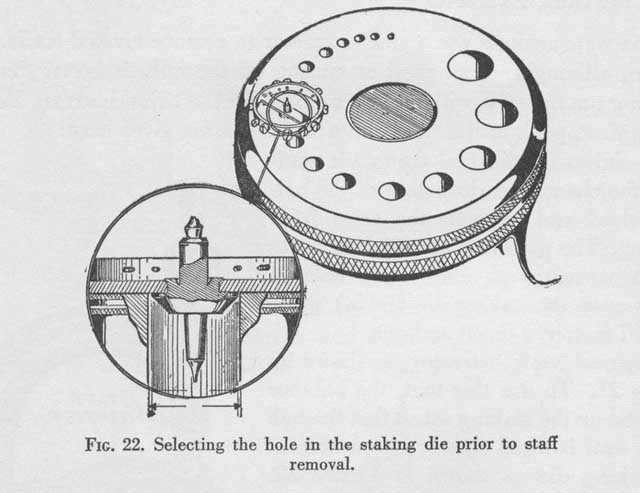

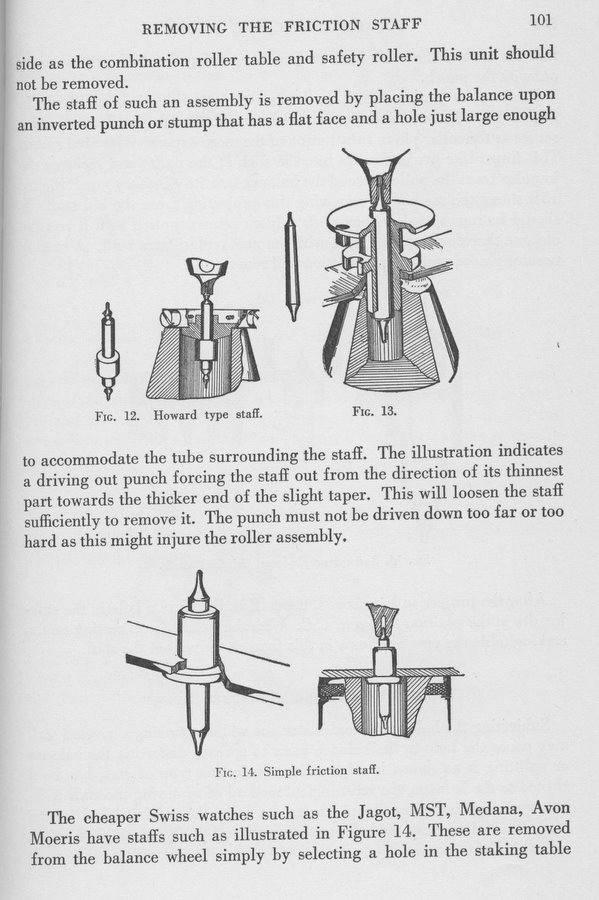

Dale, If the book is correct, you are working on a 16 size 7 jewel Elgin of which there are always many parts movements available. My first choice for that watch is to get the right 4th wheel from our master parts person, Brian Cavenaugh at; pwpartsetc@pwatch.com If you are referring to the 4th wheel as that which has the seconds had on it, I would be a little worried if the original has a broken tooth and inspect the escapement wheel and pallet for carefully for damage. If all else is well, then check the diameter of the "wrong staff" that is in the replacement wheel you have to make sure that it is not larger than the staff on your broken tooth wheel. If it is, you need a different replacement 4th wheel. If it is the same size, then you might get away with pressing out that staff and the staff from the broken wheel and exchanging them. The below picture shopws how you choose the correct hole in your staking tool to place the wheels for staff removal and reinstalling the staffs.  | |||

|

| IHC Life Member |

While the pictures and text are for balance staffs the only difference to your staffs are they are easier to do. When you have the right hole in your base plate you have to align it with the alignment tool in your staking kit, tighten the hand screw to hold it there and then pick a stake that will press out the staffs by way of the pivot end as pictured. As many of these are tapered, you have to measure the staff shaft and place the "small side" up when pressing it out, and then press the small end of the staff in first when re-assembling it. Of course you also need to makee sure you accurately measure the depth of insertion to make sure the wheel is "stacked" correctly when in the movement.  | |||

|

| IHC Life Member |

Your best bet (on the long and short run) is to go to Amazon.com and buy a cc of "The Watch Repairer's Manual" by H.B. Fried. | |||

|

Thank you so much for the information and the diagrams. I have been on that pwpt site looking at replacement parts, but haven't really wanted to spend that much money on one part for a movement that I am just learning on. I might purchase a 290 movement that is offered on another site and use it's parts. I am working my way through the 700 pages of the Chicago Watchmakers correspondence course and have thought about also buying the Fried book. When I started this, I had to decide between one or the other, so I went with the course first. And I am waiting to receive the K&D Staking Tool book so I understand more about how to use that. I've experimented on some old watch parts and have already learned quite a lot that way. There are so many books and tools I want it's hard to figure out just where to start! But I have managed to fix the mainspring and see the wheels spin, until that broken tooth, and am excited to learn it all! Thanks again for the help! | ||||

|

| IHC Life Member |

Dale, Please do not confuse the two very good parts resources we have. The one you refer to as "expensive" is Jim Liang's. He is selling a large inventory of brand new LaRose pocket watch replacement parts at; www.ptpwp.com The reference I made to Brian is completely different. Brian has a large inventory of original watch parts that he has carefully broken down so that he can provide us with New/used "factory made" replacements. He is not as costly as PWP, mainly because (in my opinion) Brian does this as a service for our group and not to make a living. Again Brian's e-mail is; pwpartsetc@pwatch.com | |||

|

Dale, I agree with David, check with Brian, parts and service are always been first rate. Good luck. Gary | ||||

|

Oh! Yes. I did confuse the two. Thanks for the clarification. | ||||

|

Update: I went ahead and tried the repair and all went very well. Now the wheels all turn smoothly. And I got to use my staking set. Thanks for the advice. I didn't realize there is another section on this forum for technical questions, so I appreciate the answers. I've been on some forums that flame you for a mistake like that! The watch people on this forum all seem very civilized. | ||||

|

| IHC Life Member Site Moderator |

Dale That is one of the main reason we are all over here, all of us were new to this at one time or another & I can say I don't think anyone here is perfect. I think we all get enjoyment from helping one another & seeing what others are doing. You are always welcome here. By the way, glad it all worked for you! Tom | |||

|

| IHC Life Member |

Hello Dale.... You have just experienced first hand one of the reasons IHC185 is one of the fastest growing Horology sites on the internet.... We do not 'shine' folks on....ever, and the expertise you experenced from Dave in his offering of help and experience in solving your problem is typical of our membership, throughout.... As you go about increasing your knowledge of 'Watch Repair' you will need additional advice and we hope that you will remember us here at 185 and come back to visit us from time to time and remember that membership here is only $12.00 a year and I don't know of any place that one can get such service so cheaply.... You may want to consider joining our group and experience the complete spectrum of our club.... I've provided a link for your convenience.... Join and Support IHC185 Come back to see us soon.... Regards, Jerry | |||

|

I will join soon. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  how to remove a pinion from 4th wheel

how to remove a pinion from 4th wheel

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  how to remove a pinion from 4th wheel

how to remove a pinion from 4th wheel©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide