| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  What a safety Pinion really does!

What a safety Pinion really does!

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  What a safety Pinion really does!

What a safety Pinion really does!Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

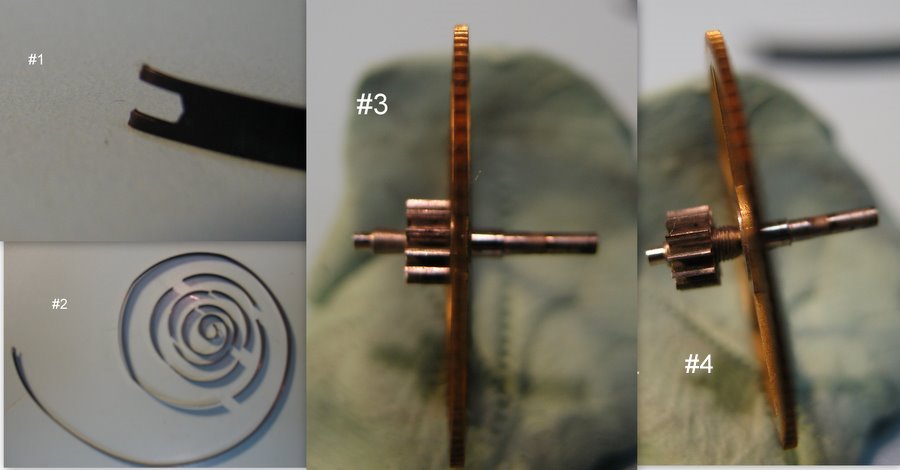

One of the uniquely "American" pocketwatch inventions is the "safety pinion" that is proudly inscribed on 99.99% of our watch movements. For the longest time the Swiss stubbornly refused to adopt this to the great chagrin of their customers when the mainspring went "whacko" The pictures below show this little jewel at work; 1. Main spring end "pop's OFF" at full wind! 2. In about 1/1000 of a second the main spring releases all it's power and in doing so self destructs (in this case into 10 separate pieces 3. The main wheel with it's "pinion "meshed" to the main spring barrel . . . 4. Gets hit with the enormous torque shock of the breaking spring that is driving the barrel backwards. The SAFETY PINION instantly unscrews harmlessly leaving the mainspring barrel to absorb and contain all the pressure. Without this feature the wheel train is destroyed.  | ||

|

Nice pictoral demonstration David. Thank you | ||||

|

Thanks David, you are amazing! | ||||

|

David, Super job was done by you on the safety pinion's function and how it works. Thanks, Pete | ||||

|

David, I was asking me always; what means "safety pinion" where is it, how is it working. You know I am a beginner. Understood. Thank you very much. Bulent | ||||

|

Nice job Dave. I think this will help more people than you think. Brian C. | ||||

|

David, great post ! I'm an absolute beginner, but I have been able to grasp the matter easily: you have been absolutely clear. Please go on posting things like this. Thanks a lot ! | ||||

|

| IHC Life Member |

David, Nice post about a much overlooked invention. I have seen many good antique swiss watches basically destroyed because the center pinion had violently spun and torn away from the soft brass surround of the center wheel it was once riveted to. Almost always impossible to repair and if a spare part can't be found, that's pretty much it. Really a shame in many cases. But not so with American Pocket Watches, the pinion simply comes unscrewed which is very, very nice. I've got a question though, since the safety pinion is also referred to as a "patent" pinion, could it be that the rights to use this device were simply not available to the Swiss? Maybe due to competition? William | |||

|

| Railway Historian IHC Life Member Site Moderator |

David: If a picture is worth a thousand words, yours are definitely worth four thousand-!!!! Good presentation. | |||

|

| IHC Member 376 Watchmaker |

good pictures Dave This was a big improvement for watches and saved a many a good watch from broke pinions ,cracked jewels etc...Some of the frist saftey pinions had a pin on the center wheel and a slot (for the lack of a better word) on the pinion you will see this on some of the early Elgin and waltham watches. When the saftey pinion is screwed down don,t tighten it up too tight or it wil not do the job it was supposed too do..I did some repair work on a 18 size elgin and the sfatey pinion was so tight it did not screw down and did quite a bit of damange too the watch,,Finger tight is enough.. | |||

|

| IHC Life Member |

I agree Samie, I have seen the early Safety Pinions with a 1/4-turn lock, so they liked to fall off while I was assembling the plates unless everything was kinda in the right place. But they sure "worked good"! The "too tight" pinion almost cost me a Waltham 1877 Key Wind when it actually "flattened" most of the Escape Wheel teeth and broke off the pallet fork. Fortunately Brian Cavenaugh had parts that "saved the day". The train on that 77 was heavy enough to propel a Sherman tank ( Whenever you reassemble these pinions, "finger tight" is as far as you ever need to go. Also, some of them have a small friction washer at their base. "Watch for it" as you are putting things back together. | |||

|

Once again a gem explanation is found when least expected! As a newish member, I have the fun of going back through all of the past postings and reading great stuff. This one finally allows me to understand exactly what that "Safety Pinion" really meant. Most excellent, David! | ||||

|

| IHC Life Member |

Thank you David, great pictures also! I had one come off and had no idea that was what it was! Will that also help to minimize the damage if you forget to wind one down before taking the movement apart. Regards, Larry | |||

|

Great post Dave, Thanks. I had seen this happen only once, I bought a watch that the mainsring had broke, and the safety pinion did its job. Jack | ||||

|

| IHC Life Member |

Larry, the safety pinion will not save damage to dry pivots that can be caused by this almost super-sonic unwind but will "save the day" if the spring breaks during an accidental "let-down" or the spinning mass of the unwinding mainspring barrel recoils "hard" at the end of "unwind". | |||

|

This is a great engineering design example...the great beauty lies in its combination of simplicity and effectiveness. And so good it became ubiquitous...until Dave reminds us its there and doing its job. Gary | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  What a safety Pinion really does!

What a safety Pinion really does!

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  What a safety Pinion really does!

What a safety Pinion really does!©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide