| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  My Hamilton 952 project watch

My Hamilton 952 project watch

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  My Hamilton 952 project watch

My Hamilton 952 project watchGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Hello all, I purchased a Hamilton 952 a few weeks ago that was pretty rusted up. The mainspring was a pile of slivers, the hairspring was rusted into non-existence and the there were a few other issues, at least the balance staff was still good! I proceeded to clean and service the watch (first higher-end bridge watch I have ever owned hint, hint - embarrassment sets in in the next paragraph). In the process of cleaning the ratchet wheel (this was the last thing I did after my 3 hour cleaning marathon since the wheel bottom was so rusted that I could barely turn it) I did everything wrong and was reading one post behind the correct thing to do to get the wheel separate from the hub. At any rate, I broke the arbor barrel hub, and the ratchet wheel In the mean time, my tinkering mindset has taken over and I was actually able to get the watch working by using a 974 barrel, and the broken collar from the old ratchet wheel as a spacer (although it is now down 2 jewels since I can not use those at the moment ... hopefully when all the parts I ordered show up I can get this watch back up to snuff). I figured I would share my experience as I feel that others can learn from my mistakes. I neglected to follow my own pocket watch repair mantra, "If something needs to be forced, you are doing something wrong." There are many axioms to this, but not following this one rule has cost me 2 jewel settings, on escapement wheel, and now a ratchet wheel and arbor hub from several different watches. Ok, now for the pics. Keep in mind, this is a work in progress and I will post a few more pics if I get the parts I need. | |||

|

This is the back of the watch pre cleaning ...  | ||||

|

This is the front of the movement ...  | ||||

|

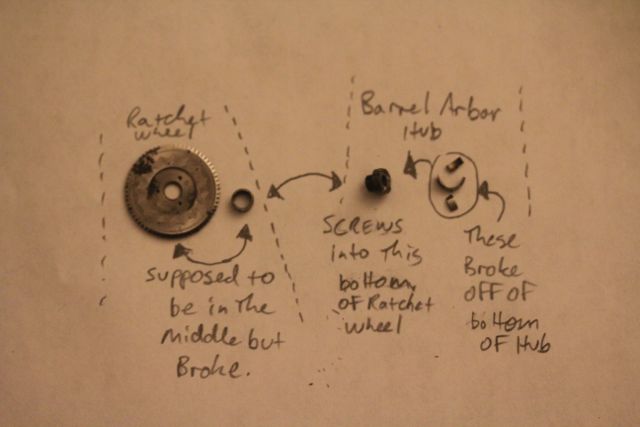

This is the busted ratchet wheel and arbor hub ...  | ||||

|

This is what the movement looks like after several cycles in the ultrasonic cleaner and a light buffing with Simichrome ...  | ||||

|

This is the front, same treatment ...  | ||||

|

And here is the Hamilton 952 19 Jewel ...er ... 17 Jewel pocket watch in its intermediate form (974 Ratchet and Crown wheel so they match and the 974 barrel). It winds, tics, and is keeping ok time (has not been adjusted of course ... that will come when I get the right parts). I do not intend to run this watch anymore or carry it, but it does work!  | ||||

|

| IHC Life Member |

Great job. Do you know if the parts are interchangeable with The illinois watches. As I have some that fit there motor barrel watches. like you 23 jewel variety. | |||

|

I am actually not sure. I do not have any Illinois watches to compare it to. I wonder if it was made around the same timeframe then maybe. I think Hamilton bought Illinois in 1927, and perhaps some of these parts would work. All speculation on my part though. I can take some measurements of the parts I have and we can compare. I think this Hamilton was made between 1915 and 1920 and from what I have read some of the parts changed from serial number 846501 forward (before 1915). | ||||

|

| IHC Life Member |

I can't check either. As I have just sold my 950b to Larry and shipped it off not even 3.5 hours a go. | |||

|

I am curious if anyone has replaced the gold lettering in any of these watches. I did not find any posts about it and am tempted to get some gold foil and try to press it into gaps where the lettering has "washed" away. | ||||

|

| IHC Member 1291 |

| |||

|

Check out Brownells.com. As a gunsmith, I have filled in a lot of lettering and engraving with a kit from them. Last time I checked the kit was called the Bonanza Gold Lettering kit and was $12.99. It contains a powder and a liquid chemical that you mix prior to application. It is a good product that I would recommend highly. It also can be reused many times. As an example, here is a photo of a S&W revolver that I customized for Tom Selleck when he was filming Magnum P.I. It had a lot of gold on it. Jon  | ||||

|

A close up of the gold filled in lettering.  | ||||

|

Buster, This will be perfect for the serial numbers on some of the project watches I have including this one! Thanks! Jon, I will take a look at Brownells for the kit you mentioned. Looks like it is exactly what I need. Watchmaker and Gunsmith! Nice! Dan | ||||

|

The watch is coming together quite well. I received the "Bonanza Gold Inlay" stuff (Actually bought it straight from Forsters Products website for Bonanza Gold Inlay as it was a few bucks cheaper after shipping) and applied the lettering last night. I will post a few pics later today I hope. But I do have a question - I had to install a mainspring as the original was non-existent. I thought the 952 could use either a 534, or a 534B and since I had more 534s, I went with one of those. I subsequently read that the 952 is actually supposed to use a 534B (and will probably try to swap that out tonight). What I am noticing is that the watch is FAST!!! It gains about an hour a day and I have already tried adjusting the balance mean time screws to slow things down a bit (it is now down to about 30 mins a day after 2 full turns on all four screws). I am guessing that the reason it is so fast is probably from the incorrect mainspring? Would that be a good assumption? Thanks for your input! Dan | ||||

|

Ok, here is the watch in its pretty much complete form. The only way it will change is if I get another case (I ended up putting it in a swing out, and I don't really like those for this type of watch, but it looked good), or if I get the right spiderweb design ratchet and crown wheel. So this is after adding the Bonanza gold inlay and polishing things up a bit. Thanks to everyone that provided input! Dan  | ||||

|

Coming back to update the postings here, but I did some more adjustments to my 952 based on some trial and error and just plain luck. As it turned out, the old ratchet wheel still had some threads left, so I was able to use one of the arbor hubs from the Cask-ers "variety-pack-o-hubs" on the old ratchet wheel. It was one that has only a few threads and I think would fit into a ratchet wheel from a later model 950 (one that does not have the shiny ratchet wheel jewel cap, and instead would only use screws to hold the ratchet wheel jewel in place. So with that being said, it was a touch too long and in order to keep the ratchet wheel from being lose and moving up and down when I winded the watch I used a 18s brass hour wheel washer to make the fit tighter. It works fine and does not bind the mainspring barrel best I can tell (might revisit this and shave off a bit to make it smaller). Now I have the original ratchet and crown wheel with the spider web design and even with the petina I prefer them over the plain replacement wheels. The next hurdle was that the watch was FAST!!!!! no matter how much I adjusted the meantime screws this watch was gaining 30 mins a day with the screws just clearing the movement and the regulator screw maxed out. (I had tried both 534 and 534B mainsprings with similar results). I examined the balance and found that the balance had 2 screws that looked like a dab of solder. I removed those and replaced them with 2 balance screws from and old Hamilton balance and with the meantime screws dialed to the middle and regulator centered the watch is only off by a minute per day. So, as you can see from the first set of pics at the very beginning of this post, the movement was pretty bad off, rusted screws, rusted main and balance springs (actually non-existent), gold lettering was faded or missing, and the demaskeeing was dirty and drab. All of that is pretty much fixed! This watch is still not even close to being perfect, but from rusty paper weight to working watch, I'll take it. And now for a few pics ... | ||||

|

This is of the mainspring arbor hub repair:  | ||||

|

This is of the balance screws. The one that is sitting by itself is one of two that was causing this watch to run FAST! and the larger one is what I replaced it with.  | ||||

|

This is of the cleaned up dial and hands:  | ||||

|

Here is the back of the movement in its new glass back case (back removed):  | ||||

|

And finally the 952 cased and ready to carry! (I know it is the wrong case, but like I said, it is the only glass-back I had left, and I really like showing off these fine movements and watching them work).  | ||||

|

| IHC Life Member |

A great job, Dan....and great to see this one back together and looking soooooooooooo good.... Thanks for keeping us updated on your project.... Regards, Jerry | |||

|

Looking good Dan! Thanks for all the insight on this movement! As you know it will prove to be invaluable when I finally get around to mine! | ||||

|

| IHC Member 1610 |

Great job! Well done! | |||

|

| IHC Vice President Pitfalls Moderator IHC Life Member |

Good going Dan, a very inspirational story. Best Regards, Ed | |||

|

A great job dan, and I like the work on the thomas magnum gun. Do you still do gun engraving? I have some work to my duty pistol i'd like to have done. | ||||

|

Thanks again everyone for the tips and comments. I hope this info helps people as much as this site has helped me. I learn something new on this site everyday, and like to see when folks post how they did something just to share the knowledge and to hopefully help some other watchmaker get a timepiece up and running again or looking better. As for the gun engraving info, that was Jon Harting. He recommended the Bonanza Gold stuff. It is pretty easy to use, just remove whatever pieces you plan to add the gold lettering to and make sure you protect or remove any jewel settings or things that you don't want gold lettering paste on. I does clean up, but it was tough getting it off of one of the jewel settings! Somethings I forgot to mention as I read through the old postings that I used a plain old toothpick to get most of the rust off. It actually flaked away in chunks but you can still see some pits where it actually did eat or wear into the movement a bit. I did a lot of rust removal before buffing movement with simichrome for the final polishing. Dan | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide