| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Dial Merger

Dial Merger

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Dial Merger

Dial MergerGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Does anyone have any experience taking two dials and making one? How do you remove the solder without damaging the dial? Do you use solder or other materials to make the joints?....Robert | |||

|

I found out, by accident | ||||

|

Thanks Jerry...What I have is two Hamilton dials that have oposite problems. The dial is the type seen on the "E" models (RR Track edge).Simular to the "B" dials except they are not marked 23. They are very hard to find. Just thought I might end up with one good one. Thanks again Robert | ||||

|

Oh, by the way. I try to save the old solder to re-use it when I put the pieces back together. It is a special low-temperature solder -- I think it is bismuth solder. If you can't salvage the solder, jewel shellac should work. I would not use anything permanent. | ||||

|

Robert HOw did your dial marriage work. I have a perfect Ham RR dial for 992 with red canadian 24 hr markers, except for a hugh chip in the seconds dial. Got a seconds dial, now I need someone to pump me up with confidence to go do it. BTW, the hands look GREAT. Thanks. Charlie | ||||

|

Charles, That Ham RR 992 dial has been sitting there, watching you, look over that perfect seconds dial long enough, it's just waiting on YOU to make it perfect! It's a shame to make it wait any longer, the DIAL knows you can, GET CRACKIN! Am I weird or what? Seriously, what a wonderful thing it would be to see them together. Yes, you can make a mistake, but since it's been on your mind, it's time to give it your best shot. Do all the prep. you need to, and remember that there are too many here that can help you, to wait any longer. Go for it! Robert & Jerry, It's so great to see wonderful information like this here. I may never repair, or work on a watch, but it's comforting to know that others share like this, so that a collector can find what they need for their Gems. Nice. Sheila | ||||

|

| IHC President Life Member |

Sheila's... "GET CRACKIN!" ...is exactly the reason I've never tried the procedure under discussion. I think Jerry's... "Proceed with caution and only if the two donor dials are truly basket cases to start with." ...is advice very well-taken. Step-by-step pictures would be great! This could get interesting! | |||

|

LOL I knew someone would catch on to that statement! Just trying to make him nervous enough to get the juices flowing again. Sometimes it starts as nervous, then turns into getting the fidigits, then finally a "Fire under the B*tt" to make us move on it. Of course, I would expect one to take ALL necessary precautions BEFORE starting a project like this one. I would LOVE to see the procedure on this topic too. Really interesting huh? Step by step pictures would be OUTSTANDING! Great idea Lindell! Sheila | ||||

|

To repair dials, I use a different approach. For the past 30 years, I have very successfully reassembled both DS dials and attached seconds registers to SS dials with Elmer's glue in lieu of solder. It is non toxic to materials around it. It dries clear and any excess can be easily removed. It holds fast, and it can be removed if the dial must be taken apart. You can't tell the difference. Granted, it is not solder, but don't knock it until you have tried it. Professional watchmakers have all the equipment and materials to do the job. We, who are amateurs, must use what we have available. Tom | ||||

|

Well, I took Sheila's advice (actually I was finishing up while she was typing) and gave it a shot. Used Jerry's suggestions on the high intensity lamp on a basket case dial that could not be resurrected. Left it on too long, burned the dial, the block of wood it was on and the screw holes on the halogen lamp the held the lense on. It was a true double sink and was in 3 very brown pieces. Got back in my pile of uglies and started "unsoldering" a seconds bit with one of those little soldering irons from 30 yrs ago used for electrical wiring. Unbelievable how easy it was and the sec bit just fell out. hmmm. Got my donor dial out and unsoldered that sec's bit. Looking good. Grabbed the good dial with crunched sec bit and unsoldered it. With a warmed up soldering iron it only takes a min or two to unsolder it. Practiced resoldering on the crushed donor dial and the crushed secs bit, and it worked like a charm. The donor seconds bit fit right into the gapping hole on the good dial, with only minor trimming of solder particles. Scotched taped it into place, melted pieces of the original solder back into the grove, and it was done. It only takes a spec of solder in a couple places to secure the bit, either removing or replacing one. I encourage you to try this with some beyond-help dials. You will be surprised. I will post a pic of the finished dial since I did not do before, during and after pics. I will have to remember to document the process with pics on my next adventure with the trusty ole soldering iron. Thanks again to Jerry and Steve Maddox. I got most of the how to from early post I had searched on, using solder as the search word. Charlie | ||||

|

charlie, a heated griswold skillet works good for removing the centers. getting the three good pieces back together is the tough part. if you make a wood peg that fits the center hole snug enough that you can actually pick the dial up with it,,, then set the dial on the cast iron pan feet down you can use a small amount of down pressure... when it gets hot enough it will drop out (seconds bit too) but you can get it all off the pan fast with the makeshift peg. | ||||

|

Sounds like good ideas here and methods to try.I have a few dials i may in a later time try my hand at repairing.I would for sure start with a dial that was pretty far gone and see what comes of it.I like your expression Sheila, get crackin. | ||||

|

Charles I never got around to trying the marriage of the dials. However, I am still interested in giving it a try.....Robert | ||||

|

I as sure there was some beginners luck involved... luck in that the two hamilton secs bits fit so well. They almost snapped together when "switching". I'll post a pic as soon as the ceiling fan is installed ! Charlie | ||||

|

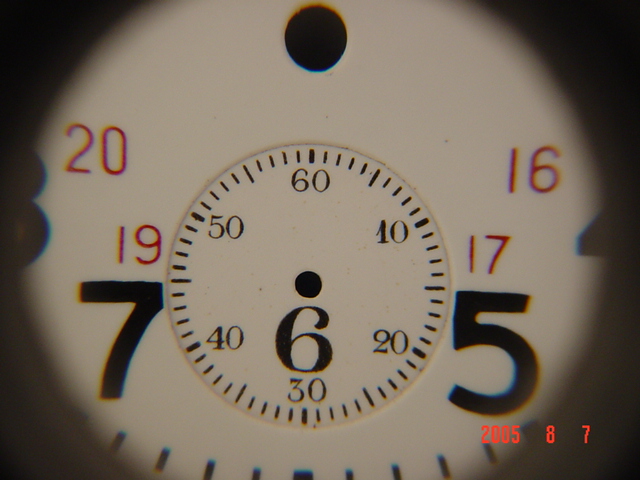

Here's the after pics. You'll have to take my word for how bad the original seconds bit was chipped. Think HUGE hole.  | ||||

|

seconds bit  | ||||

|

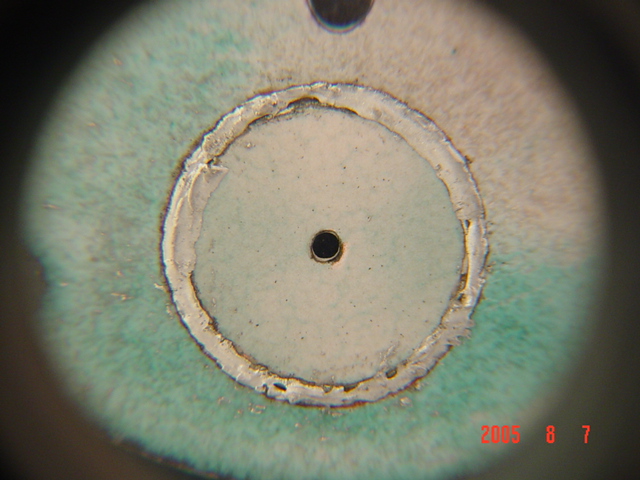

back  | ||||

|

| IHC President Life Member |

Absolutely beautiful work Charlie. You've given me the nerve to try experimenting sometime soon. Lindell | |||

|

FANTASTIC! Thank you for posting the Dial, it's really wonderful. Congratulations! Sheila | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide