| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Staffs and jewels are no more problem for me.

Staffs and jewels are no more problem for me.

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Staffs and jewels are no more problem for me.

Staffs and jewels are no more problem for me.Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

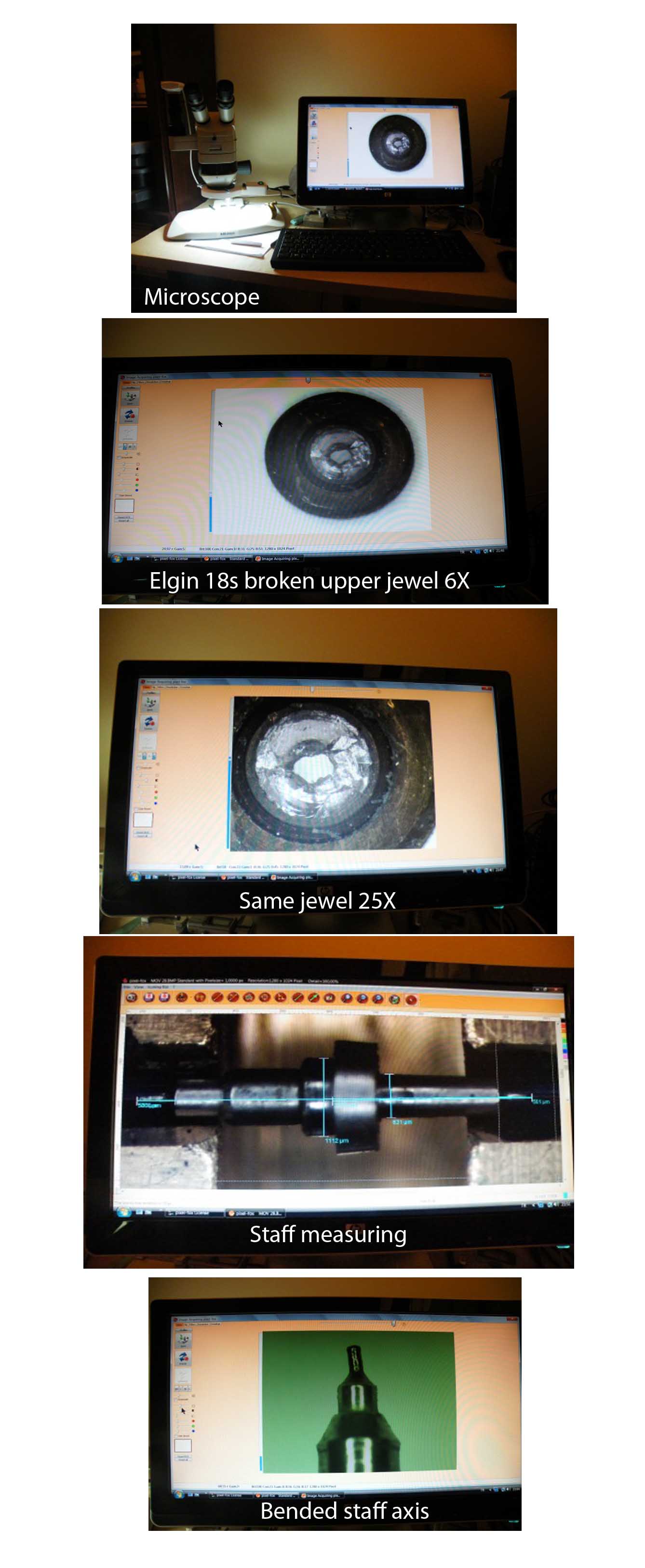

I am very new in the world of pocket watches. Just 21 months. For me the most difficult things are staffs, jewels and hairspring. Since 3 months I have a new assistant. With his help, determining, measuring and replacing a staff or balance and plate jewel are no more problem. Actually I have 2 more problems: hairsprings and roller plate jewels.I need some more time. Please take a look to my assistant. His name is Mitutoyo 377-975. The program is Pixel Fox. Nice week-end for everybody. B. Ogel  | |||

|

Oooooh -Ahhhhhh! A stereoscope hooked up to a computer! Sweet! That's what I call getting up close and personal, Bulent! M. | ||||

|

| IHC Life Member Site Moderator |

I like that Bulent, I have often thought of doing that, I have an old stereo microscope that I have thought about some how attaching a digital camera too. Nice! | |||

|

Wow, what a great piece of equipment to have. Ray | ||||

|

After looking at that jewel I am sure it would be a "staff eater", slowly but surely. | ||||

|

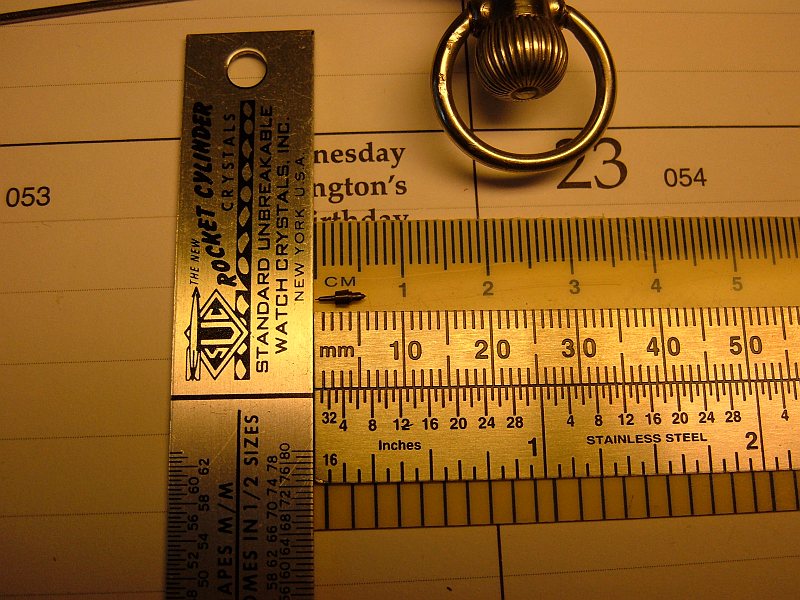

Just found this post from 2009. This is exactly what I need for my tired old eyes. With today's current technology I'm wondering what would be the equivalent or close to it, without having to buy a microscope. Would a good camera do the job? Here's a poor example. I'm trying to measure a staff. Yes, I have calipers but find it very difficult to hold the part and get a measurement. Dave Turner  | ||||

|

| IHC Life Member |

Dave, You can get measurements easily by putting your staff in a pin vise. I usually put one end in rodico and then pick it up with the pin vise. Then flip it around for the other measurements. For length, I lay it down on the rodico and push it in a little so it doesn't move around. I admire the oldtimers who were able to make these parts in short order with little or no magnification not the best of lighting, and gravers that were scalpel sharp. It takes me hours under a microscope with great light to turn out a nice piece. I paid around $200 for my used microscope and it is one of the best investments I ever made. The picture shows the microscope over my one of my Boley lathes. | |||

|

Dave, I bought a digital caliper and had a difficult time getting accurate measurements. The blades of the caliper were to thin at the measuring point and balance staffs are small. The caliper was also big, about 11 inches long. I went looking for a better way. I found a used small micrometer on ebay for $10 with a max measuring distance of 10mm. I have found its just easier to measure smaller parts with a smaller tool. | ||||

|

Thanks for the tips, guys. I was thinking about the rodico trick myself. I'll look for another type caliper. Nice setup Roger! Dave Turner | ||||

|

| IHC Life Member |

Roger, I am very impressed with your microscope and lathe set-up. I am looking at a similar boom-type stereo microscope on eBay, but they offer so many different models, I don't know which one to pick. From reading their literature, it seems that for watch work, less magnification is better e.g. 7 X 45 zoom. I guess the ones going up to around 90X are for looking at bacteria, omebas, etc. The one in the link below only has an 8w florescent light. I don't know if that would be sufficient, or I should pick one of their models with 50 or so LED's. Your advice and tips would be greatly appreciated! http://www.ebay.com/itm/7X-45X...&hash=item1c2eecded0 | |||

|

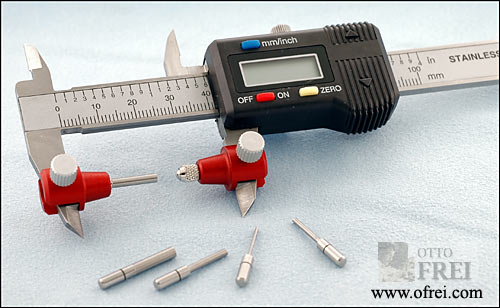

Dave you could also go this route. It helps when using the caliper.  | ||||

|

| IHC Life Member |

Bruce, My microscope is an American Optical Cycloptic Stereoscopic model. I am no expert on microscopes and was lucky to find this at a mart where the owner demonstrated for me how it functioned. This is a very old scope, but I think ideal for watchwork. It has a dial to change magnifications with different internal lenses. The eyepieces are 15X. The important things to look for IMO are the working distance, which is 4" on mine...that allows 4 inches between the lens and your workpiece so you have plenty of room to work under the lens, and the field of view, which can be very small...like 1/2" or less. Comparison of size of detail to the magnification range is important. In other words if you want to work on a balance staff pivot you need to be able to focus the scope to that size. One other thing is the quality of the optics. Today there is so much junk out there you have to be careful. Hope this helps you in your quest for a scope. Roger | |||

|

| IHC Life Member |

Thanks Roger. I sent an email to the seller of the scope I was considering on eBay. I wanted to know the name of the manufacturer, country where it was produced, etc. At the bottom of the description it lists two standards that have been met by the scope (or maybe they are organizations that have given their blessings on this machine). I still need to investigate what those organizations are and what the standards are. Thanks for the advice on working distance. That will be important if I want to use the scope with my Boley/Lienen lathe. | |||

|

| IHC Life Member |

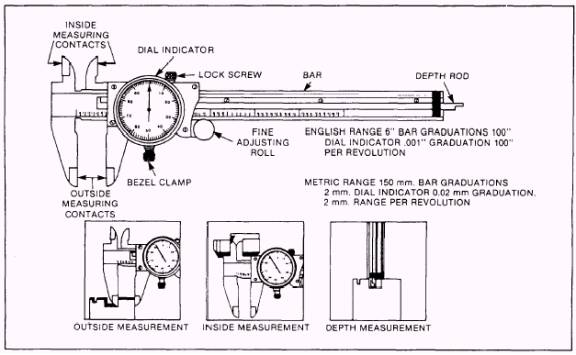

A good vernier is most important to us when working with staffs and "practice makes perfect" to make measurements. A dial vernier scaled in (.001) inches of reasonable quality is far easier to use (for me) than ANY of the digit reading types for several reasons; 1. The Staff ends are usually tapered and I need to know the maximum "fit" measurement taken at the terminus between that diameter and the larger diameter next to it (such as the "shoulder"). 2. When measuring new staffs to make sure they are correct, I use the vernier as a "comparator" meaning that I note the same dimensions in the same places of both staffs to confirm their "sameness". The actual numbers mean little the "same" numbers mean everything to a successful replacement. To that end a dial vernier seems (to me) to be much easier. 3. Dial verniers work all the time, "batteries not included". As far as "DIY" staffs, I leave that to Vladimir because the pivot ends are past my range of expertise. We need to find a shop that can step up to the plate and make staffs we need. I have a friend in Oregon who can do that but he needs some idea of what and how many we need.  | |||

|

| IHC Life Member |

Bruce, I too am in the market for a scope. After using them for years in microelectronic assembly, they just seem to make sense for inspection of watch parts, as well as lathe work. I suspect they'd also work well for bench work, but you'd need a regular height workbench rather than the higher watchmaker's bench. In my experience, the light source is really important for the usefulness of the zoom scope. When I was using them, fiberoptic or fluorescent ring lights were preferred. I suspect the LED ring light would be good as well if there's a decent diffuser in front of them. I would not recommend the goose-neck style. My guess is that any of the scopes in our (my) price range will be Chinese, but optics technology has improved a lot, so they're likely good enough. You could always try to get a Carl Zeiss, but those run in the thousands used. | |||

|

| IHC Member 376 Watchmaker |

Roger i have a scope and stand just like yours i bought 2 of them at the Drawbridge show in Ohio a few years ago 200.00 each i belive was the price i paid.,The guy had several of them, i used one and have the other seting in the conor of my shop, next time i go too a show i will probaly sell the extar i don,t need it. They are several years old but the optics is great and the stand weights a ton. | |||

|

| IHC Life Member |

I have decided against the OMAX scope that I first provided a link for. I read some negative feedback on them on Amazon concerning certain features. The link below is for an AmScope on Amazon. Seems to be built a little better and reviews were better than with with OMAX. I think they are both made in China. http://www.amazon.com/AmScope-...cope+boom+microscope  | |||

|

| IHC Life Member |

Evan, My scope and lathe is on a watchmakers bench and is the perfect height for me...I'm pretty short at about 5' 5.5". The picture shows a recently made part that I'll tell more about in the near future. Bruce...You may want to consider Samie's scope. It would be a real bargain. One thing I didn't mention earlier is the weight of the base. As Samie points out they weigh a ton. It is important that it be heavy so there is no movement of the scope while you are working. Shipping might be a problem because of the weight. | |||

|

| IHC Life Member |

Roger, Do you work on the lathe standing up? If so I'd agree that the higher bench could work well. Can't wait to hear about that staff! Evan | |||

|

| IHC Life Member |

Samie, I'd be interested in the scope if it has a light ring (and if it makes sense to ship and you want to mess with it). Evan | |||

|

| IHC Life Member |

Bruce, Here are a couple scopes that I've used in the past and can vouch for, but they're more than I want to spend. Wild Zoom Scope $1800 B&L Zoom 4 no lamp B&L The B&L are work horses, and good mag/working distance as well as depth of field. Just wish I could find one with a decent light source for under $500. Evan | |||

|

| IHC Life Member |

Yes Evan, I stand at the lathe while working. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Staffs and jewels are no more problem for me.

Staffs and jewels are no more problem for me.

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Staffs and jewels are no more problem for me.

Staffs and jewels are no more problem for me.©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide