| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  P.S.Bartlett Movement.

P.S.Bartlett Movement.

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  P.S.Bartlett Movement.

P.S.Bartlett Movement.Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Hi all, Venturing into this forum with a recent acquisition of a Waltham P.S. Bartlett movement that came in a Waltham shipping container, and wondering if anyone can give me some info about it. Is it junk, run of the mill, or a reasonable find? Paid around $40 for it as a job lot inc shipping. The container is shown in the Waltham database, I doubt the movement and container started life together. All and any comments appreciated! Best regards John  | |||

|

Another movement view. The movement is crippled at the moment, as the mainspring barrel cap is off, and the bridge is loose - note odd screws too! Rest looks reasonably ok though. John  | ||||

|

Dial looks perfect other than being very dirty, No chips, hairlines etc. Sunk seconds dial is good too, and no chips on any edges. What sort of hands would have been used with this? I'm assuming blued steel 'Spade and Poker' ............. or would they have been Gold / Silver. What is the general consensus of opinion as regards recasing this piece? I have several Sterling silver cases, which I'll be having a root through to see if anything is suitable. They're all for KW/KS movements, but I doubt the inner domes will be drilled in the right place for the winder. All in your hands folks, any help appreciated. John  | ||||

|

| IHC Life Member |

John, I suggest that you confirm common serial numbering for the major parts. If all the numbers match, and as this is an 1872 vintage P.S. Bartlett model 1857 11 jewel watch with "A" grade finishing, it would be a fine piece to restore. The original Hands would most likely have been blued steel or black. Given that it is a Key Set watch you need a square hole Key Setting Minute Hand, and whatever style minute hand you find then dictates what you use for the hour hand. If there are any "odd" screws, including the one you mention on the barrel bridge, check their tapped hole with a "normal" screw and confirm they have not been "repaired" to use a different (odd) screw. As for parts to restore this, our very own Brian Cavanaugh at pwpartsetc@pwatch.com can usually help you if you can give him a description of the parts you need. | |||

|

Thanks for that Dave, appreciated. It caught my eye on the bay, and I'm a sucker for crippled watches .......... sometimes I even get 'em going again I've a few similar Waltham plates with odd bits left on them, any idea if Waltham's were into parts interchangeability back then too? I can probably rob screws off them when I dig them out if so. The balance is a bit tight also, so there's issues in that dept, pivots seem ok though. Time to get the tools out! I'm already building a list up for Brian, got quite a collection of busted Walthams now! John | ||||

|

John, If I'm not mistaken it's a model 1857, and if it is, it can be worth from $150.00 to $800.00! Of course, that depends on what it actually is. It sure is good to see a nice dial for a watch of that age. To me, it's a keeper! How many jewels? Sheila | ||||

|

Sheila, you really know how to make a guy smile .... keep it goin' gal! Wanna buy a watch??? I was quite surprised by the dial to be honest, I thought it would have a few chips around the edge, but nothing, it's absolutely flawless other than for crud. Considering how tight it was jammed into that shipping container too, it's a miracle it survived. The photo on the listing was quite poor, but the style, plus Bartlett name and that jewelled train did it for me, I'd a hunch I wouldn't go far wrong with it. I know a little bit about English and Swiss watches, but I'm a total rookie when it comes to stuff with American provenance. I'll let you know about the jewels when I disembowel it, not a clue at the moment. I can see 4 train jewels plus a ruby roller and the balance end stone at the momonet, but what's lurking under the dial, no idea. I've got a few projects done to get published on the boards now, but think I'll have to make this one the next priority. About time you folks saw some gear I've dragged back to life. John | ||||

|

I forgot to ask the last time, can you tell me what the serial number is? is that a second 7 after the first, or a 1? either way, I think it's still an 1857. I think it's pretty rare to find a dial like that when it's sent in those cases squeezed in like they are sometimes. I also posted a message to show your silver cases so how about posting some you dig out for this watch on that message? Last, How about a showing of your finished watches? When? I would LOVE to see them. Sheila | ||||

|

Sheila, It's a second 7 - serial 637794, hopefully as Dave has suggested, the numbers will all match. I've still to dig the cases out of store, so I don't know if any will be the right size yet. If I find one that does fit, you'll hear me whoop from your place I've got a load of photo's done of a few watches now, plus a longcase clock I did in France last month (now thatWas a challenge!)! I'm busy reducing the images to fit the boards, but the clock will make an appearance a little later. Now that one really Was an ugly duckling to a swan! John | ||||

|

oooooooooooooooooo aaaaaaahhhhhhhhhhhhhhh sounds sweet. Oh, and it IS a model 1857 Sheila | ||||

|

| IHC Life Member |

John, This should be a pinned dial, remove it (be very careful to recover the dial pins and SAVE them!) to confirm that this is an 11 or 15 jewel watch. Then BEFORE EVEN ATTEMPTING to reduce the watch further, I suggest that you get some isopropyl swabs ready and soak the wheel pivots and friction jewels to soften the "rivets" of fossilized fish brain oil that has hardened into little "heads" that break off balance, train wheel and pallet pivots. If the balance wheel is stiff, it too may be riveted" to the jewels, and for that you may have to see a watchmaker. Our "1-dip" (a nasty nitro solvent which kills you if you breath too much) does break down fossilized fish brain oil, but an experienced watchman usually has some "trick" up their sleeve to preserve the Balance staff pivots during removal of the balance wheel from the dirty jewels. Then to take the plates apart, first establish some meaningful end-play in each wheel by reaching in between the plates with your clean well sharpened #5 tweezers, CAREFULLY pull up on the top plate watching the pallet through the balance wheel entrance hole to make sure it is not "teeter tottering" at an angle and breaking its pivot. After that it's not much more than fixing a clock! | |||

|

Well, I got it torn down ok, and no danger of fish brains gumming up this one Dave, think the microbes lunched on it all! Other than being incredibly filthy, it's actually in quite nice nick. Numbers appear to match, there's a '94' scratched on the underside of the balance arm, and 94 stamped into all other plates and bridges. The curious bit is alongside or below the '94's, is '17', not sure what this signifies unless it's mismatched parts or the number stamper goofing putting the '1' instead of a '7'!!. The balance was stiff because the barrel cap was rubbing on it, free as a bird as soon as the bridge was taken off, good hairspring and pivots plus jewels are sound as a pound!. It was overbanked though, which was probably the result of the broken mainspring that fell out when the barrel and cap were lifted off - probably why the cap had been shoved back on the barrel and left loose. Tried the good bridge screw where the oddball one was, and it's good! threads not damaged at all. Checked all the train wheel teeth and pivots closely after the mainspring discovery, and all is sound, nothing bent, cracked or missing.! Once I've cleaned up all the plates, pivots and pivot holes, I'll check see how bad the wear is and re-bush as required. There's certainly some side float on the centre pivot even though that at least looks good. The hour wheel is glued to the cannon pinion with rust, so that will need some careful tweaking to get it off - had to pull the whole lot off as a unit with a pin vice. Sheila, the movement is an 11J type if it helps!I'm fairly happy about losing a few jewels on the spec, because the balance staff and jewels are good ....... sort of quitting while ahead Anyway, first shot up is of the barrel catching the balance. John  | ||||

|

And, this is what lurked beneath! Curious extra slot in the cap edge, maybe the botcher couldn't get the mainspring end pin in place! JW.  | ||||

|

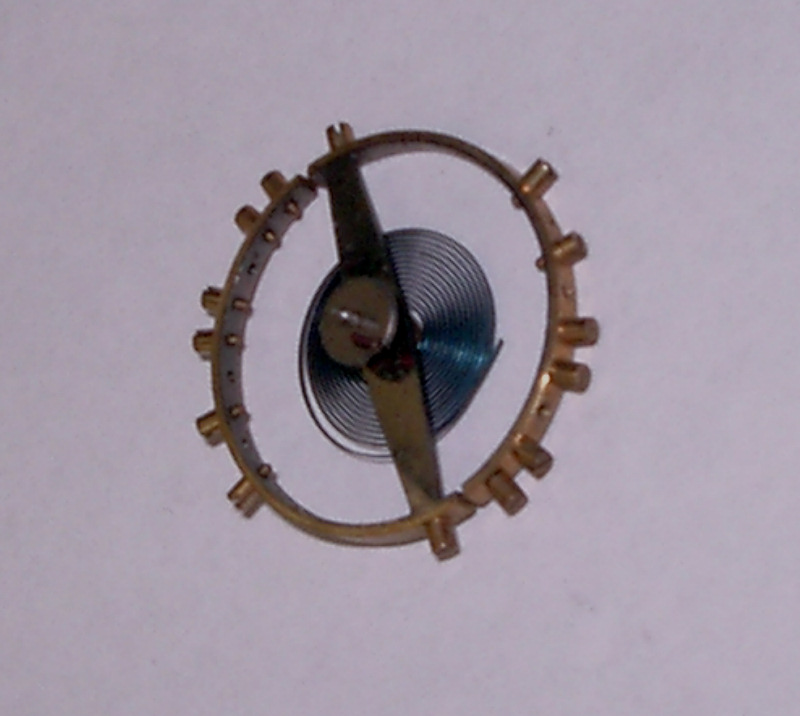

Good balance, pivots and flat blued hairspring - no rust!. As you said Dave, steel balance, and a cut bi-metalic type at that. Think all the timing screws are present but need to take another look later. JW.  | ||||

|

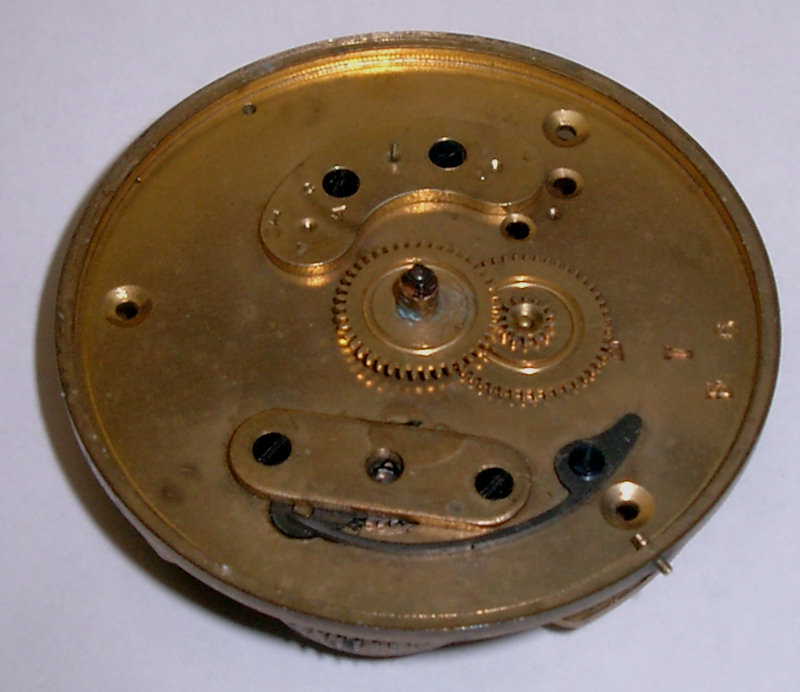

Dial side, lots of muck but no jools! Doesn't appear to badly worn and numbers appear to match. JW.  | ||||

|

Better shot of those nice big jewels, will see them even better when the gravel pits are emptied! JW.  | ||||

|

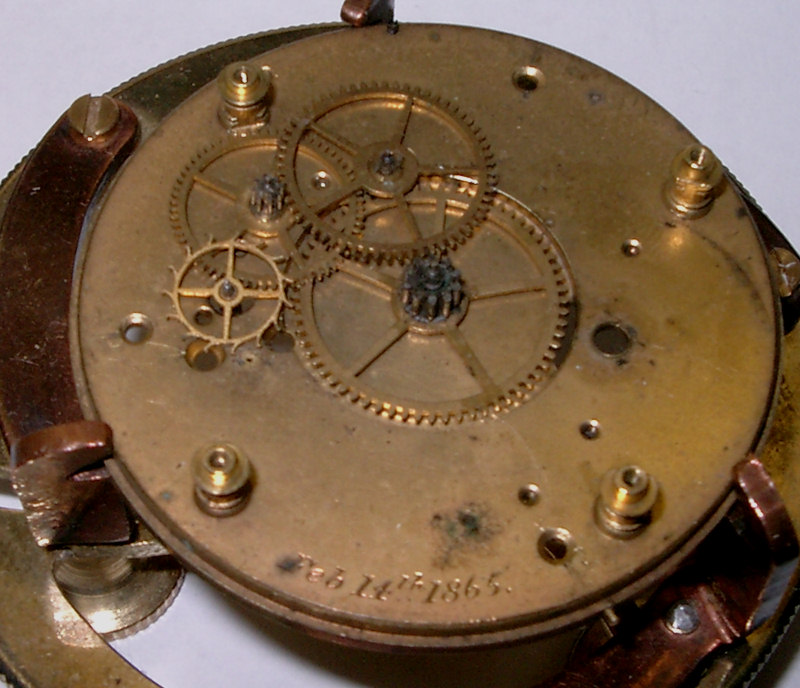

Very dirty train, plus a bent seconds hand pin, hopefully it'll straighten ok without breaking. Pallets absolutely clogged and barely visible through the gunk! Note the date engraved into the plate! Anyone know if that's a patent or manufacturing date??? J.W.  | ||||

|

Finally, a shot of the underside of the top plate. Very strange alteration to a banking pin, that's probably going to be the tricky bit to repair because the screw slot is also chewed up. Hopefully a pin out of one of my similar'bitzers' will be suitable. JW.  | ||||

|

Nearly forgot the hour wheel and cannon pinion! Apologies for the blurry quality on many of the photo's, think I'm going to have to replace my camera as the macro focus isn't anything like as good as it used to be. JW.  | ||||

|

John, Your dangerous, you make me want to take my watches apart. Until Russell went into the hospital, I was going to finally clean one I have, that's already apart. Since then, I have taken my home apart and couldn't, but now I have the itch back. Between you and David, with his instructions, and you with your great examples, I almost can't keep still. I only have one more room to do, HAVE MERCY! Now maybe I will get a watch desk up and running. I have thought about it for years, so I guess it's time. Keep up your progress, it just may get me off my B*tt and get going. Nothing like going to school ONLINE!!!!!! Sheila | ||||

|

| IHC Life Member |

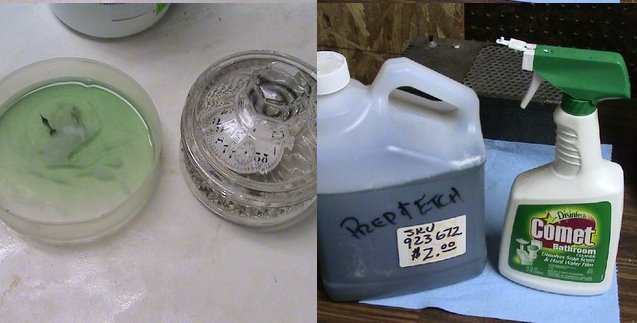

John, Very good work so far. I suggest that you concentrate on cleaning things, and avoid taking too many more things apart until you can see through the goo and rubbish they are coated with. If the seconds wheel staff is exiting through the correct spot, please leave it alone, as it WILL break if you try to straighten it. Also at reassembly be gentle with pressing back on the seconds hand. Regarding the two cover plates on the top (dial) side, I would remove the cover, spring and "click" for cleaning, because you will be reassembling those anyway AFTER you have installed the newly wound mainspring and barrel at reassembly (or you will go nuts trying to "fish" the spring arbor end into the click gear.) It is so much easier to just put it on after the plates are together on the othwer side. I would leave the other (pivot) plate that is held on by two screws alone, just clean it and the pivots. Removal and reassembly could mess up the wheel alignment. For the "rustbound" Hour Wheel/Cannon Pinion, try to find the concrete CLEANER (GREEN STUFF) used before coating concrete driveways. It is formulated to remove metallic oxides only, and works very well on rusty ferrous stuff and "green" copper based stuff. As a passive rust remover soaking parts in it will help de-rust and disengage things like the Hour wheel from the cannon pinion. (It also de-rusts watch hands and pallet forks) When you decide to remove and clean the balance jewels, press them out with a piece of pegwood so they are not cracked by the force. If they argue too much use more isopropyl for a few hours and try again. The pic shows the green cleaner and also the dial cleaner I use, whith some hands beiung rerusted and a dial being de-"hair-lined". The green stuff is excellent for this because it only removes the rust, then you just re-polish things and you are "back in business". FINALLY  | |||

|

Hey Sheila, you got that room done yet, time you scratched that itch and got some watches cleaned and tickin' I recon, I've given you a couple o' weeks to get sorted, so hows about it ???? Sorry about the delay coming back with a reply though, we both share similar pressures in our domestic lives - I think you'll get my drift there! Also had big problems with my photo's that were saved. When I went to edit them for posting, they'd all been saved as PSP images, which is ok as that's what Paint Shop Pro uses, trouble is none would open, just a blank page. In desperation, I let Windoze do a web search for a programme that would open them and it came back with Adobe CS3, (I'd used a trial for a time) so downloaded another trial copy and spent more than a few hours resaving hundreds of images as .jpg's ......... grrrrrrrr So, hopefully will be able to post some old resto projects for you now. Best regards John | ||||

|

Dave, Thanks for the heads up on the quirkier side of Waltham movements! Not had a lot of time of late to do much with it, but some progress has been made as regards cleaning etc. The bent pivot will have to be straightened because the hand pipe will catch the dial otherwise. I do have a very neat Bergeon tool for straightening pivots which works well enough on balances, so should eat this little job - there's also the nifty watchmaker's trick I use of warming the pivot with heated tweezers beforehand! The banking pins are coming out! I'll either make new ones or try get some out of a donor. One of them is a complete botch and made of bronze rather than brass, and it's also sawn half through on the pin itself, and both have been a bit too chewed to leave in a restored movement. I hear what you say about the banking pin adjustment, but that also presupposes that they were adjusted correctly by the botcher that put the dud pin in place to start with. ........ they probably weren't! Any idea what the UK equivalent is of the magic brew that you use for cleaning? I'd hate to get the wrong stuff and see my bits disolving in front of my eyes Did that by accident once with some horolene ........ very clean brass bits, but a heap of rust for 'ex' pinions and pivots Best regards John | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide