| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  4oz Sterling Case

4oz Sterling Case

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  4oz Sterling Case

4oz Sterling CaseGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

After 2 months of being "stuck" in cool, beautiful Flagstaff, I'm once again down south, near Nogales, Arizona on the Mexican border. The "watch-shop" is near here and now I get to begin the real work on my summer acquisitions at the National and elsewhere. First, however, there was the weekend. The monsoon rains have come to Arizona and my place here is overrun with weeds and overgrown vegetation. A watchmaker should not have bend over and pull weeds in the hot Arizona sun but that's exactly what I did for two days. I hurt! But... Monday morning, I'm again at my bench with the opportunity to dissect watches. First, on the list is a simply horrid acquisition that has potential... It is a ho-hum Hamilton 924 in a 4 oz, Sterling silver, CWC case. The excitement is the case. 4oz cases were not the norm and sterling cases were quite unusual. The best part is that I bought this for a song on ebay because it was so incredibly ugly. You'll soon see why. The case is old and very high quality but totally neglected and abused. It has a very low SN and that number is repeated 5 times on all the watch parts (bezel, back cover, bezel ring, and twice on each of the flip-out rings). The bezel is interesting as well because it holds the crystal with a threaded bezel ring rather than with glue. I'm told that this is quite unusual. But first, scroll down to see why it was so cheap. Not only was it incredibly dirty but I now know that it was PAINTED black as well. I'll try to post "after" pictures as the restoration progresses. Today, I dismantled and cleaned (ultra-sound and buffing) the paint off the case. I also replaced the cyrstal which was ok but has some tiny scratching. I chose the thickest one that would fit. I also disassembled the movement and cleaned that as well. It now awaits oiling and reassembly. But, now... here's a really UGLY watch! | |||

|

Does anyone know why someone would paint a perfectly good watch black? Is it possible that it was painted years ago just to turn-off ebay bidders?  | ||||

|

The back is even worse. The black paint is thick here too. The three dots are deep dings. It looks like someone had this in a vise or pliers. I'm tempted to try to pound them out and then try to restore the shape with aggressive buffing. Being 4oz, it is a very heavy case and I have a lot of silver to work with. But... for now, I'll leave them alone. I'm trying to restore a fine case... not ruin it.  | ||||

|

The dial is good...not great... with a couple of hairlines that became nearly invisible with cleaning. The arrow points to a thick accumulation of crud that prevented the bezel from screwing all the way down. Also, note the bent hinge pin that prevented the movement from seating fulling. That was repaired as well. I'm sorry that I don't have a photo of the bezel ring that holds the crystal. I found only 2 service marks inside the case which is clearly marked "4" (oz) and Sterling. I'll leave off the movement, which is pretty vanilla 924. Perhaps I'll include a shot after it's cleaned. This is a bit risky because the watch is not yet restored. If the project fails, I'll have nothing but a post on a putrid watch that ended in the junk-heap. Of course, I was and still am very optimistic that this will be a superb case.  | ||||

|

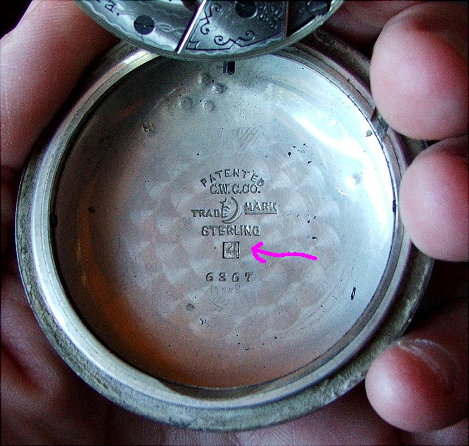

One more shot, showing the inside of the case and it's markings. Also note the three "dots" which are the damage seen on the outside of the case. I still can't figure them out. This shot does not show the crown which is well worn and gold-colored. I would prefer a silver crown in much better shape and I understand that they came in both colors. But, so far, I've looked through a couple hundred crowns and have not found one to fit. I might have to simply use the old crown until I can locate one that fits. Note, however, the very low serial number which might explain why I'm having so much trouble finding a replacement crown.  | ||||

|

Thanks for sharing this project.... you are holding the watch and can make a better determination of 'paint'.. but i just want to bring up the point that silver cases will patina and oxidize to a heavy black color..... have seen some engine turned cases that are black, but have no wear.... some like to leave those alone and not polish this patina away... keep us informed with the process!! | ||||

|

When I saw the item on ebay, I was convinced that it was tarnish. I considered that a plus because it indicated, to me, that the watch had been ignored for ages (which is what we want). But.... look at the image of the dial with bezel removed. Look where the paint has lapped up onto the gold ring of the pendant. That was the first tip-off that I was dealing with paint rather than tarnish. Your point, however, is well taken. And I hope that when I complete this project, and this thread, it might lead to discussions about the extent and scope that our restorations ought to take. This is not unique to horology. The process of cleaning and restoring old objects, whether watches, paintings or other valued works, by necessity changes them. I would expect such a discussion to generate many opinions. After all, our watches were "working tools" and were often cleaned and repaired during their useful life. Just like other fields, where restoration and cleaning is controversial, we will never resolve it but it should generate endless discusion. Query: When you view the cleaned and restored ceiling of the Sistine Chapel are you really viewing the master's work? But.... are you really viewing it, if it is left dirty and in ill repair? | ||||

|

Peter, I have a Deuber Silverine case that also has the blackened finish. When I got mine several years ago in a junk box, i made the same assumption as you did--it was tarnish or corrosion. The more I polished, the more I brought out this black finish. I thought mine was a fired on finish, rather than paint. Mine also shows the knick of wear on the back as yours does. I had thought that maybe mine was done by its owner, but now, I wonder if there was a process in case making for doing this. Also, I have seen several cases, but not a lot, with the threaded bezel for holding in the crystal. I think it's a nice touch. Great find. Tom | ||||

|

If that finish was factory-installed on your Silverine case, I have trouble believing that the factory would do that on a Sterling Silver case. It would seem to defeat the prupose of making the case in Sterling. But, I'm open to argument from anyone who has information. I finished the watch today. I doubt that I'll have time, tonight, to post all the photos but I will post at least one. | ||||

|

The Hamilton 924 and the 4oz,Sterling Silver case were finished today. I’ll just post one photo now and perhaps more later. The movement was oiled and reassembled but more on that later. The case was also reassembled after cleaning. It presented me with a number of compromises but I was adamant about replacing the worn, brass crown. In my opinion, nothing looks better than a sharp crown. We searched literally hundreds of old crowns to find just a couple that were large enough to fit the pendant. Then, of course, the likely candidates did not fit our stem. So, we began another time-consuming search for a stem…. which, in turn, had to be cut to fit. The new crown really “finishes” the case. Cases look deceptively simple but I have spent many long hours trying to find case parts and fit them. In my opinion, a pendant sleeve is one of the hardest parts to locate and fit. I’ve also made more mistakes in casing watches than I’ve ever made working on the movements. It’s always heartbreaking because casing comes at the end of a project, just when you feel you are about to succeed. I had to compromise on the NOS crystal. The ultra-thick crystal, I chose proved to be too thick and it hit the dial even before I set the hands. With quite a selection of thick NOS crystals, I found that the original crystal was my best bet. It was not in bad shape but I longed for a NOS one. Lucky the 924 movement is lever-set… making the installation of the sleeve and stem much easier than in a pendant set watch. The end product is quite spectacular by comparison.  | ||||

|

Very nice for sure! Aaron | ||||

|

Peter, Terrific job on this project! Thanks for sharing this one with us. | ||||

|

I thought I'd post one more picture showing the unusual bezel and the "retaining ring" design for holding the crystal. I've never seen this system. The ring was quite delicate and difficult to work with. It had to be held completely level to screw in, like a case-back or one would risk cross-threading. But, unlike a stiffer bezel or case-back, it was far more delicate. We had to "invent" a tool to do it. Our "tool" consisted to two staking tools held vertically in a small vice at exactly the proper distance to engage the two detents in the ring. The the assembly was turned upside down and the ring installed. Otherwise, it seemed impossible to get it right. The case, including the retaining ring, has matching serial numbers.... five of them.  | ||||

|

| IHC Member 163 |

I LOVE these big old monsters. This was a GREAT job, sir. Thanks for sharing! High regards! Mark | |||

|

This is the wrench used to remove the reflector on these patented 18-size silver cases so that one could change the crystal. The label reads: "This wrench is to accompany the Waltham Patent Dust Proof, glass bezel, now being introduced on Waltham Screw Bezel Cases. It holds the glasses firmly and closely, absolutely excluding all dust and moisture, without the use of cement. It will permit the use of several different sizes of glass. It is the only perfect Dust Proof Glass Bezel ever made. It will be recognized by its Gold Reflector." I have seen this reflector ring on Waltham and Crescent cases.  | ||||

|

One of the most interesting and most fun things about antique watch-repair is finding one of the millions of tools that were invented for every task.... and using it. Boy, I wish we had that tool. Our jury-rigged tool worked ok but we spent a lot of time trying to start that ring by hand.... with no success. Every one of those weird tools had a purpose and every one made the job easier. Today, we sometimes cannot figure out what some of them were for. I actually was successful in my first attempt to change a pallet jewel, even though I used the pallet-heater upside-down! And thanks,everyone, for the compliments and kind words about the project! | ||||

|

| IHC Life Member South-Bend |

Very nice Peter! Let's see a movement pic! Frank "407" Kusumoto | |||

|

Ahhhhh. It's going to be difficult to describe my experience because Lin has this site set-up to filter most of the words. I'd like to use. First of all.... I LOVE to work on 18sz, full-plate watches. I learned some tricks-of-trade and putting on the full-plate holds no terror for me. I can pop a full plate off and on in less than 5 minutes. So, I had no problem with the Hamilton 924 movement that came with the watch. The 924 is considered a "ho-hum" movement and I had no reason to believe that it was original to the watch. But.... after all.... many of the finest solid-gold hunters have cheapo 7 jewel movements. I ususually take considerable time in the disassembly of a new movement. I check each jewel and pivot carefully for wear. I'd like to know about problems BEFORE the watch is assembled. I found no obvious problems. And the movement then went into our 5 ultra-sonic baths and rinses and then into the drier for at least 20 minutes. The watch was then properly greased, oiled and reassmebled, with no problems. The watch "ran" as soon as the balance was installed but it had an action that, even to the eye, didn't look great. Some tweaking of the hairspring collet improved the action and I put on the canon gear and moved to the vibrograph. I have never seen such a terribly timed watch... even in the early stages of adjustment. In different positions, I had a watch that would run as much as 5 minutes FAST in one position and 4 minutes SLOW in another. I eliminated the obvious problems.... jewels and pivots and determined that it was probably due to the installation of an improper hairspring. Perhaps this belongs in the "Pitfalls" forum but this condition (albeit not always this bad) is not unusual for ebay watches. Many of those watches are made from "left-over" parts and are true horological abominations. For those collectors who only wish a watch to tick... I have to wonder what horrors are now being "preserved." (But I digress). My choices were, at that point, to spend some considerable time and money to locate and install a proper hairspring to an uninteresting 924 movement, find another 924 movement or just leave it alone. The case is what attracted me to this project and the whole watch only cost me $130.00 on ebay. My decision was to try to get the watch to "time" in a position or two and begin to look around for another movement (of another higher-end model) to replace the 924. (I know this is controversial but I have no reason to believe that the 924 was "native" to this case). My "fix" was to add 5-minute washers to opposing timing screws on the balance wheel. This brought the watch (more or less) into proper timing in the pendant-up position. The other positions are still ridiculous but the watch keeps time when sitting in one of those little plastic watch supports on my dresser. In my opinion, the 924... and especially an ebay abomination 924... is simply not worth the time. I have a H-946 in an identical case and there are some rather rare 18 sz movements (in the 930 series) that might be proper (in period) to that case. So..... that's my story. Anyway...here's the movement. It looks nice and clean but.... beauty is only skin deep!  | ||||

|

I have one of those cases also. Its a large Illinois. The case is silverois but the reflector is bright rose gold. I think they are really cool cases. Nice job by the way. Aaron | ||||

|

Make sure the staff pivots are good, then true the balance wheel and poise it. Then adjust the hairspring if needed.This should solve some of your problems. J Smith | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide