| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Hamilton Balance S.R. Balnce Staff

Hamilton Balance S.R. Balnce Staff

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Hamilton Balance S.R. Balnce Staff

Hamilton Balance S.R. Balnce StaffGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Member 1610 |

I'm tired of searching. Can someone tell me if there is a section on Hamilton Balance staffs. I have a real good reference guide on Hampden Balance staffs and I was hoping to find something similar for Hamilton's. I am trying to find out if the model 974 and model 975 SR use the same balance staff. I think they probably would but I would like to know where and if there is a reference guide for future reference. Harry | ||

|

| IHC Life Member |

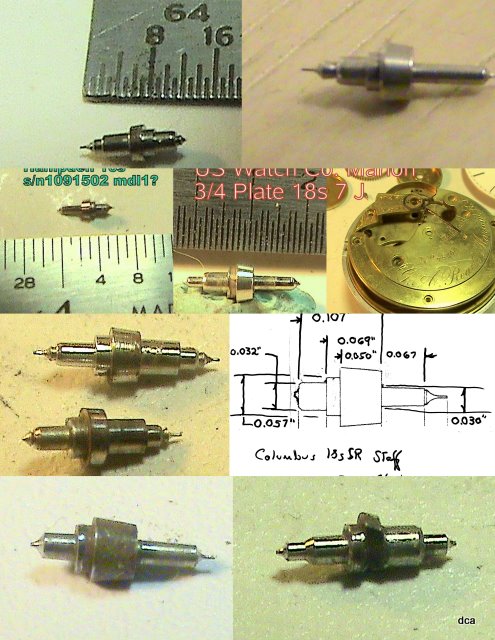

Harry, Sadly many Balance staff designs were modified by the manufacturers over time to the chagrin of watch service people from the beginning to this very day. Generally you can say with some confidence that the same balance staff could be used on similar period movements of the same exact type as with the 974 and 975, but then you have the issue of the pivot sizes. Making generalizations about balance staffs is ill advised. I have to apply my "machinist's eye" to each and every staff I replace and carefully measure all of the relevant diameters, check the lengths, jewel fitments, make any adjustments possible and necessary, and then pray it works. Fortunately, if I cannot find the right staff in my own generous inventory, I can contact Brian Cavanaugh who has been able (with a proper picture and description) to supply one about 90% of the time . . . including the variants of Hamilton staffs, some of which are in the below collection of our communications of a few months past.  | |||

|

| IHC Member 1610 |

Hello Dave, I have replaced several SR balance staffs and with original NOS and they have always worked. Luck I guess. I don't have precise enough measuring equipment to measure the pivots at the ends of the balance staffs and even if I did I have no equipment to measure the jewel hole. So for the DYI how do you repair these watches. I've been lucky so far I guess. I am sending Brian a photo tomorrow on a Howard 16s series 9 balance staff to see if he has one. The reason I need to find out the 975 balance is so I can replace the staff on that unusual export model. You remember the one made without the second hand. The dial has been redone and is on it's way back so I need to fix the balance staff or have it fixed. I don't know anyone who works on watches so I don't know who does good work and who just does it to make a buck. I have not been able to find the diamond cut Hamilton hands but I do have a 974 movement with a very nice metal dial I can take the hands from but then I would need some fancy hands for that movement. I would like to get started on the export model so I can get it running. You got me all excited about that watch and since the dial is on it's way back I really would like to get the balance staff fixed. As always Dave thank you for taking the time to post replies to my questions, Harry | |||

|

| IHC Life Member |

Harry, remove the broken staff from the interesting 975 you have and send a picture of it to Brian so that he can best identify which of the SR variants it is. I have little doubt that Brian will "err" on what he finds for you. Just be ready to polish the pivots (if need be) to fit the jewels. I generally use a "steel" for the "near" fitment ones and a fine tiny triangular arkansas stone and then steel to gently reduce oversize ones followed by a "rouge polish" after they pass fitment. For superior watch repair and restorative work I strongly recommend our very own Chris Abell. | |||

|

| IHC Member 1610 |

Thank you Dave. All great advise that I will certainly take. I will do that tomorrow with Brian since I need to do that with the Howard anyway. I have seen Chris Abell name several times here and when I need some work I will definitely contact him. Thanks again, Harry | |||

|

| IHC Member 1610 |

Oh Dave I forgot. Could you tell me what a "steel" is? Thanks for the tip on the Arkansas stone. I will see if I can find one. Thanks, Harry | |||

|

| IHC Life Member |

This is what I use; | |||

|

| IHC Life Member |

and Rouge . . . | |||

|

| IHC Life Member |

If it is oversize, I GENTLY touch it up with the Arkansas Stone . . . . | |||

|

| IHC Life Member |

and I always polish it with my "steel", using the sharp edge and the radiused edge . . . | |||

|

| IHC Life Member |

Then I give it a light "kiss" with Rouge . . . | |||

|

| IHC Life Member |

and finish the job with a pegwood "shiner". NOTE: These pictures are representational only, the staff is not all the way into the lathe collet, and I did not actually perform the tasks, only took pictures of what it looks like. dca) | |||

|

| IHC Life Member |

Dave's comments about staff measurements are right on. Without doing all the preliminary work, you wind up with a hack job at best. The first time you put a 12 size pivot in a watch that has 11 size jewel holes and screw down the balance cock, you will hear the sound of breaking jewels. If you put an 11 size pivot in a 14 size jewel hole the balance will wobble all over the place. Dave didn't even mention the other important part of staff replacement...that of poising the balance, which must be done if you entertain any notion of the watch running well. It's great to see people wanting to fix these wonderful old machines, but make no mistake, without the proper tools and know-how disaster lurks around every corner. | |||

|

| IHC Member 1610 |

Thank you Dave and Roger. Using the lathe it makes a lot of sense now. I have used a lathe before when I was in metal fabrication many, many years ago. I do not currently own one so I can forget that method. I have sent Brian the photos so we will see what we shall see. I do not have a lot of tools and even though I have a posing tool I don't know how to use it. But that is just another thing that is on my list to do. Thanks, Harry | |||

|

| IHC Life Member |

We all have to start someplace Harry and I hope I didn't sound discouraging. We need as many people as possible keeping these wonderful little machines alive. Acquiring the tools and knowledge is an ongoing process. As a suggestion, you may do well to get a bunch of low-end movements and learn on those. It hurts a lot less to damage a $20 movement than a $200 one. | |||

|

| IHC Life Member |

Dave I want to give you a pat on the back for all the informative information that you so freely hand out. And also for the way you treat everyone and every post that I have read of yours. I look forward to the day that I can shake your hand and thank you in person. | |||

|

| IHC Member 1610 |

I agree with Eugene 110%! | |||

|

The info Dave gives is helpful to more than the person who started the thread, and will be for many years to come. What I took away from this is what other tools I will need for my new lathe for pivot sizing. Thanks Dave. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Hamilton Balance S.R. Balnce Staff

Hamilton Balance S.R. Balnce Staff

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Hamilton Balance S.R. Balnce Staff

Hamilton Balance S.R. Balnce Staff©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide