| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Just when you think you "seen it all"!

Just when you think you "seen it all"!

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Just when you think you "seen it all"!

Just when you think you "seen it all"!Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

Guess what?!  | ||

|

I have seen it before! In an 1883 waltham... It was binding in the barrel and causing the watch to stop. Almost in the same place too. I would only have to assume that they didnt have a replacement or the customer didn't want to pay for a new one. | ||||

|

Good grief! You never know what you will find under the hood of some watches. I guess nothing should cease to amaze! | ||||

|

One step in the same direction if you go to ebay and search the antique pocket watches using "raymond" you will find a B W Raymond in a star stainless steel case that someone tried to electroplate it with gold. The description was "part of case is peeling off" What possessed someone to attempt to electroplate a star stainless case is something beyond me. | ||||

|

| IHC Life Member |

I bought an Illinois Stewart Special last year that I thought had a really cool looking dial. When I took delivery I found that the dial had no feet and it was fastened to the movement with double stick tape | |||

|

| IHC Member 1110 |

Some people should not be allowed to work on ANYTHING! That spring, besides the butcher job rivet, looks "set" so bad it would blow the barrel cap off...Merry Christmas! | |||

|

| Site Administrator IHC Life Member |

We shouldn't be too harsh with innovators. Remember this Honda commercial from a couple of years ago? Imagination. Rube Goldberg | |||

|

| IHC Life Member |

We don't know when this was done and it could very well have been at a time when material was in very short supply. Better a working watch than no watch? | |||

|

| IHC Life Member |

Its really fun to make this kind of post and see what the reactions are. Thank You all for being here! | |||

|

David-you've no doubt seen other innovations such as brass pin roller jewel and super glue balance weights? Here's a new one I came across: a balance screw used as a banking pin. (on a 19J Bunn) | ||||

|

Hello David, Here is another kind of repair you probably haven't seen before. This Elgin came to me with a broken staff and a badly mangled hairspring. I couldn't straighten out the hairspring and finding a replacement was quite a hopless task, so I had to improvise with what I had at hand. As you see from the picture, I had to splice a lenght of hairspring to the one I had in order to achieve the proper vibration frequency. The watch has ben working with acceptable performance for quite a long time now. I didn't do this in order to fool some buyer because the watch is part of my collection and all watches of my collection must be in working condition...one day somebody will wonder.... Personally I admire people who can get things working again with improvised means, as long the "thing" is not permanently damaged and can be put back in the original configuration once the proper parts become available. I must say that I too was tempted at one time or another to repair mainsprings, but I never did it. Your picture demostrates that "in a bind" it could be possible, if properly done. I like to think that the owner of your watch was travelling in India when the watch broke down and some local artisan in a small village took it upon himself to make it work again...I've seen people in that country performing prodigious mechanical feats with very modest tooling. Well, that's it,..HAPPY NEW YEAR TO ALL! Peter | ||||

|

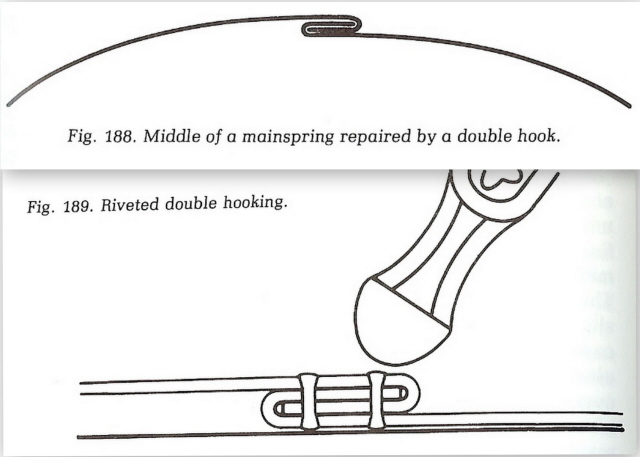

I actually read in a repair manual once that broken mainsprings could be repaired temporarily by heating the broken ends and bending them in opposite directions and hooking them back together. I have even seen watches with this done. seems that the temporary repair turned out to be the permanent repair. I once made a tiny sleeve to repair a broken fourth wheel on a watch that parts were not available for. I cut the top off another fourth wheel with the same diameter shaft,and ground the original shaft down so the total length was the same as the original fourth wheel,and put the two parts together with a sleeve made from a small piece of hypodermic needle. It worked great,and the watch is still running several years later. | ||||

|

Hello Cecil, Yes, the repair method you described is an acceptable one, but generally applicable to bigger clock mainsprings (as can be seen from the image below). Speaking about extreme repairs, I see I'm not the only one using sections of hypodermic needles as sleeve to repair shafts and staffs. I have in front of me an old "New York Standard" (18-1890)that is working quite well with the upper balance pivot coming from a section of an unrelated donor staff. It is held in its place by a microscopic section of an hypodermic needle and (horror!) a few molecules of krazy glue for insurance.  | ||||

|

Hey, I think it's great that we still have the brains to figure out how to fix things like this. If we are anything at all, we are inventive, that's for sure. However, I still have to admit, that your photo did make me freek out! hehe Thank goodness the only really unusual thing I ever had to deal with, when I opened a watch buy was unraveling a bunch of stringie kind of stuff from a mainspring. Came right off, and worked fine too! (for some reason, it didn't work for the seller) hehehehe DDDDAAAA! Sometimes ya just gotta love the ones that have no idea what they have. Love this post. Sheila | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Just when you think you "seen it all"!

Just when you think you "seen it all"!

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Just when you think you "seen it all"!

Just when you think you "seen it all"!©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide