| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Military Timepiece Discussions - EXCLUSIVE!

Military Timepiece Discussions - EXCLUSIVE!  Seeking advice/help on finding parts that seem near impossible to find

Seeking advice/help on finding parts that seem near impossible to find

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Military Timepiece Discussions - EXCLUSIVE!

Military Timepiece Discussions - EXCLUSIVE!  Seeking advice/help on finding parts that seem near impossible to find

Seeking advice/help on finding parts that seem near impossible to findRelated Content: Watch Repair Questions and Answers

Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

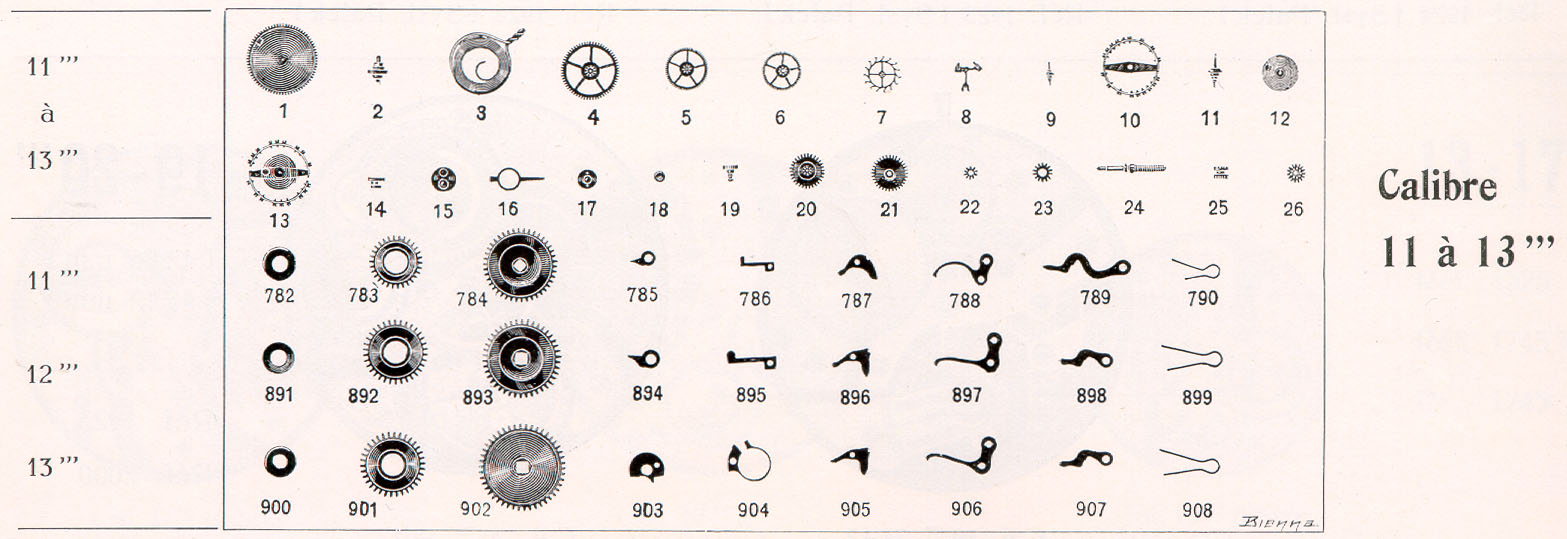

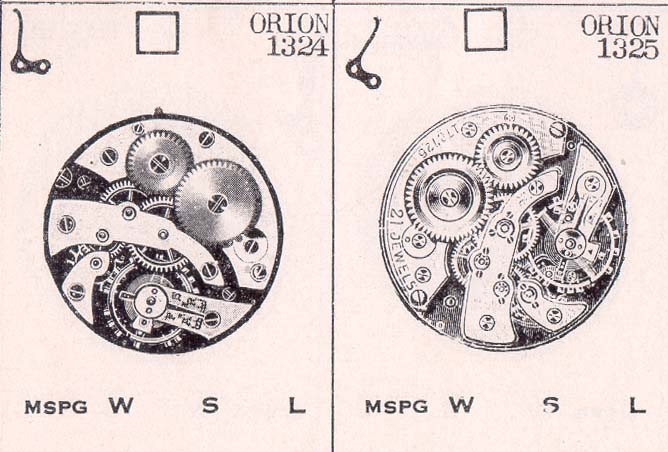

Sort of a "cry for help". So I have this old Ulysse Nardin trench watch, movement I was able to find out what it is with help from someone previously (who also supplied the great pics below), which is a 13 ligne Orion, 15 jewel. It is missing winding pinion/wheel and a third wheel (wheel that meshes with the castle pinion) and lacks stem and a crown that has a larger opening to go over crown tube. I figure stem and crown generically can be found more easily at some point. I know movement parts can be made from scratch to work, but I was told for each part it would be $150 or more for them to be made. (my jaw dropped) There may be other movements of same size and similar age and layout that I figure might have parts that would work. I've done a "hit or miss" approach on Ebay, paying $10 here and there for trench watches for parts, but the parts have been too big. Just wondering if anyone may know of some ideas on obtaining such parts. I'd love to have this thing working and wearable. Tim     | |||

|

| IHC Life Member |

Tim, It may take awhile but something will eventually turn up on eBay. I would do a weekly search in the titles and descriptions for the movement name and Ulysse Nardin watch. You might also try dashto.com. Tom might be able to help you. Good Luck! | |||

|

Tim, I've checked my Bestfit and Swiss parts books and so far haven't found any reference to either U.N. or Orion movements in 13 ligne sizes. If you can dig out any cross references to another maker (AS, Felsa etc) I may be able to help but can't promise. Even checking movement types in Bestfit using the setting levers for ID doesn't show anything remotely close. I would exercise caution buying aything on Ebay on the offchance something may fit - unless the movement is totally identical, frankly you've a better chance of winning the European lottery, so hang onto your money, you would almost certainly be better spending it having parts made! Even 'common' Swiss watch movements of the same ligne of that era consume an Insane ammount of time to source parts for from other movements. I have boxes full of the things, (mostly 10 - 10 1/2 ligne) and from experience can tell you that if you put 100 movements on the desk, you'd be lucky to find more than a couple with anything in common at all!...... even from the same manufacturer. Sorry to be the bearer of not so good news, just don't despair at the lack of response. Fact is you have a movement in an uncommon size from an uncommon maker therefore bits will also be very uncommon! I have had a quick look through some of my stuff, but very few 13 ligne movements (that's a big watch!) and all the setting levers are different. You may be able to match up the missing wheels but the levers will probably need to be made. Where did you source the parts illustrations for your watch movement? John | ||||

|

Thanks guys. I had gotten the illustrations for the movement through someone on Time Zone, who had a book that happened to contain them. Tim | ||||

|

Orion was a trade name used by the Welta Watch Co., Bienne,Switzerland. | ||||

|

Tim, If you can indicate from the parts diagram exactly which parts you're short of, I 'may' be able to help. I've just dug out a box with a large number of 'hands setting' transmission gears, castle wheels, clutches etc, plus a bucket load of winding wheels and old 'onion' crowns, most of which will clean up ok. They've all been removed from Swiss wristwatches of a similar vintage to yours. I also have about half a dozen incomplete 12.5 - 13 ligne movements which I may rob if something is suitable. If one of the wheels is missing from the transmission train on the dial plate (appears to be), let me know the diameter of the boss on which it operates, approx height of the gear, plus the radius from the centre of the boss to the root of the gear teeth it meshes with. You may have to do some fiddling around with the bits to make fit, but better than nothing. John | ||||

|

Hello, winding pinion and wheel are standardized among Swiss makers, variations are probably no more than 20 with reference to diametres and total lenghts, the winding stem can be made to fit and then it should not be difficult while sorting the pinion/wheel in the ol' watchmaker ''trash'' bin to find also the wheel , please start to take full dimensions of the pinion/wheel recess on the platine.... rgds enzo PS _By the way, Merry Christmas and Happy New Year to All!!! | ||||

|

Thank you both! John, if I see things correctly in diagram, I'm missing parts: 22 and 26 Smallest wheel (#22) in the transmission train, one that meshes with the castle wheel. The other missing (#26) being the winding wheel. I don't have any calipers for measuring, but I can provide a rough measurement as you've requested. I figured as well, that there must be parts from other manufacturers that would essentially work/fit, but a matter of finding right size and # of teeth. Tim | ||||

|

Thanks Tim, I'll need sizes though, as all my stuff is 'second user' and just dumped in boxes, there are hundreds of mixed gears etc! All this stuff is from the estate of a deceased watchmaker who used to repair these things daily. Fortunately he hoarded all the useable 'cast off parts' and 'scrap' movements........ many of which just have broken staffs! The only way a manufacturer's code or fitment would be of any use, is if parts were available in part numbered boxes, you'll be very lucky to find any, so it's a case of measuring bits to suit! Unfortunately because of the size of the movement, there's an extra wheel in the transmission due to the distance between the hour wheel and the castle gear! Only movements of that size are likely to have them. The only alternative, is a wheel from a smaller movement which uses the size you need, hence the size needed of the stud it bears on. I'd also need a diameter of the ratchet, as this has to match the diameter of the castle gear otherwise they probably won't mesh properly. They're difficult to machine too and mostly need grinding, they're all hardened parts! The stem is 'childs play' after sorting the other bits out! I would strongly recommend you get a digital vernier if involved in repairs though, as they're also invaluable for sizing crystals and mainsprings! Any amount of them on the 'Bay' quite cheaply. John | ||||

|

Thanks John! I'll see what I can do about measurements. Very much appreciate your help on this. Tim

| ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Military Timepiece Discussions - EXCLUSIVE!

Military Timepiece Discussions - EXCLUSIVE!  Seeking advice/help on finding parts that seem near impossible to find

Seeking advice/help on finding parts that seem near impossible to find

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Military Timepiece Discussions - EXCLUSIVE!

Military Timepiece Discussions - EXCLUSIVE!  Seeking advice/help on finding parts that seem near impossible to find

Seeking advice/help on finding parts that seem near impossible to find©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide