| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Military Timepiece Discussions - EXCLUSIVE!

Military Timepiece Discussions - EXCLUSIVE!  Chelsea WWl aircraft clock

Chelsea WWl aircraft clock

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Military Timepiece Discussions - EXCLUSIVE!

Military Timepiece Discussions - EXCLUSIVE!  Chelsea WWl aircraft clock

Chelsea WWl aircraft clockGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

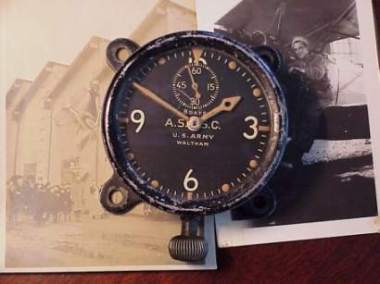

I was given a WWl Chelsea aircraft clock for repair as shown on the company's website under 1917 on the Historical page. The face is marked.. A.S.S.C. U.S. Army Chelsea Clock Co. Boston, U.S.A The back is marked.. C.C. Co. 212 January 1918 Ser.# 113755 He had found this clock mounted in an old and deteriorated wooden block so that it would sit on a desk or mantle. The really astounding thing is that the clock was in an abandoned junk yard as was actually buried in sandy soil. It looks like it might have been in the ground for years. When he gave it to me the winging arbor would not move so I assumed the clock was fully wound. The knurled bezel is virtually undamaged, but it is frozen in place. In an attempt to get it loose to examine the movement, I was able to remove the winding knob and the arbor housing. With a sharp rap of a wooden handled knife, I knocked the arbor out of the housing and wiped it down with oil. I still could not move the bezel so I reassembeled the arbor. Sure enough I could then wind the clock and it's been running now for about 5 days although it is losing about 15 minutes a day. The only apparent visible damage is that the hour dots on the face and the covering on the hands, which I think might be real raduium, are corroded. There is also some wobble to the winding knob, but it works fine. I do not want to do any damage to the bezel in an attempt to remove it. I think the bezel and case are aluminum, and there could be some varnish on them. Does anyone know of a way to unscrew the bezel without causung damage? | |||

|

Can't come up with a way to remove the bezel some one here mite be able to help you there can you post some photo's of it would like to see what it look's like. | ||||

|

Thanks for the resonse. I don't own a camera that can take pictures close enough to be really helpful, but I'll see if a friend can help me out. | ||||

|

These are nice clocks, along with the Walthams that were also used at that time. Without seeing your clock I can not say just what is the issue, but one possibility is the bezel has become cold welded to the case. Cold welding can occur when metals are under pressure for a long time and it can be accelerated with corrosion, heat and moisture. Cold welding is a molecular level bonding of the two pieces of metal. If that is what you have then you may not be able to get them apart without damaging them. And cases for these are hard to find so a replacement would be a problem. Just leaving it alone is likely your only option at this point. On the other hand, it might also be decades worth of gunk that has gotten down into the threads and over the years has cooked up into a pretty strong cement. There are some fluids on the market these days that are designed to free up bolts that you might think about, but I don't know whether they would work on aluminum or what they might do to the metal - they could damage the metal so you would want to be sure before trying one of these. Regarding the "corroded" paint on the hour markers and the hands, yes that is real radium 226 and it is just as radioactive today as it was when it was made. In other words, you really don't want to touch it and you most definitely do not want to try to remove it. The reason it looks corroded and brown is that the paint is a mixture of radium, zinc sulfate and glue. The radium is the power source and it would energize the atoms in the zinc sulfate to the point where they would give off light. The radium is strong enough that after a decade or so it oxidized (burned) the zinc oxide to the point where it was changed so that it no longer was able to give off light. The radium has a half life of over 1,600 years which means that after that amount of time it will have decreased in power by 50%, so in the past 90 years since the clock was made the radioactivity of the radium has only decreased by a very slight amount. You are okay to be near the clock, but what is really dangerous is if you get any of the dust or tiny bits of the radium paint breathed in or on your fingers and then you absentmindingly touch your fingers to your mouth and then it gets inside you that way. | ||||

|

Thank you for the response and information. If you don't know what a new or restored Chelsea aircraft clock looks like, you can go on the Chelsea website's history page and move the time line to just before 1920. From there, just click on the 1917 button and a picture of the clock is displayed. To give you an idea of the size of the clock, the bezel is about 2 7/8 inches in diameter, and the clock is much larger than WWII Waltham aircraft clocks. I have tried both 3-IN-ONE and WD-40, but I still can't move with just my finger grip strength. I don't think the mainspring is too badly set because it ran for 6 days, and I did not wind it all the way so as not to put the mainspring under too much stress. I really think a good cleaning and oiling might be all the needed repairs, but I can't tell because I have been unable to get the case open. Radium 226 is some scary sounding stuff. When I was first learning watch repair, I was told some workers at dial companies, not knowing of the danger, would paint their teeth with it as a joke or take some home with them to play with. Sadly, I figure most of those workers experienced an early demise. Anyway, thanks again for your advice. I'll let you know how I come out with the project. | ||||

|

Hi Mark, Based on your description, I believe my example may be a brother to yours. On the dial: A.S.S.C. U.S. Army Chelsea Clock Co. Boston, U.S.A On the back of the ALUMINUM case, it is marked.. C.C. Co. 146 January 1918 And on the back of the small housing that encloses the winding gears: 114125 -(this same 6-digit serial number matches the number stamped into a plate of the brass movement). By the way, mine was still mounted into a wooden Chelsea shipping box, leading me to believe it was never issued. Although some latter day genius painted the box with black gloss enamel, the impressed letters can still be read on the box: From Chelsea Clock Co Boston Mass U. S. A. -then a 3-digit number that is too distorted to read- From Chelsea Clock Co Boston Mass U. S. A. -then a 3-digit number that is too distorted to read- Ron  | ||||

|

Indeed our clocks are brothers. Yours is really a beautiful example of the family while mine has been treated somewhat like a stepchild. Can you tell me if the bezel is a two piece one? It looks like maybe the glass in sandwiched between two bezel rings, but I'm not sure. A friend is going to lend me a strap wrench to try that is actually designed to remove small oil filters . It's got a rubber strap that ratchets tight before you unscrew the filter. At least it should not damage the knurling, but, since it will have a relatively small thickness to grab onto, I don't know if it can do the job. I'll let you all know. Thanks for the great pictiure of your clock! | ||||

|

I was referring to the WW I era Waltham aircraft clocks. They are about the same size as your Chelsea.  | ||||

|

Hi Mark, Your analysis of the bezel assembly is correct. -After removing the winding knob, the silver bezel unscrews. Looking at the inside, there is a brass ring which appears to be holding the glass. The brass is a little less than 1/16 inch thick, and it appears to be a machined part. -To release the glass, the brass piece must unscrew (but I see no good way to grip the brass, it sits almost flush with the rear of the silver bezel). Ron | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide