| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Gear Cutters

Gear Cutters

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Gear Cutters

Gear CuttersGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member Certified Watchmaker |

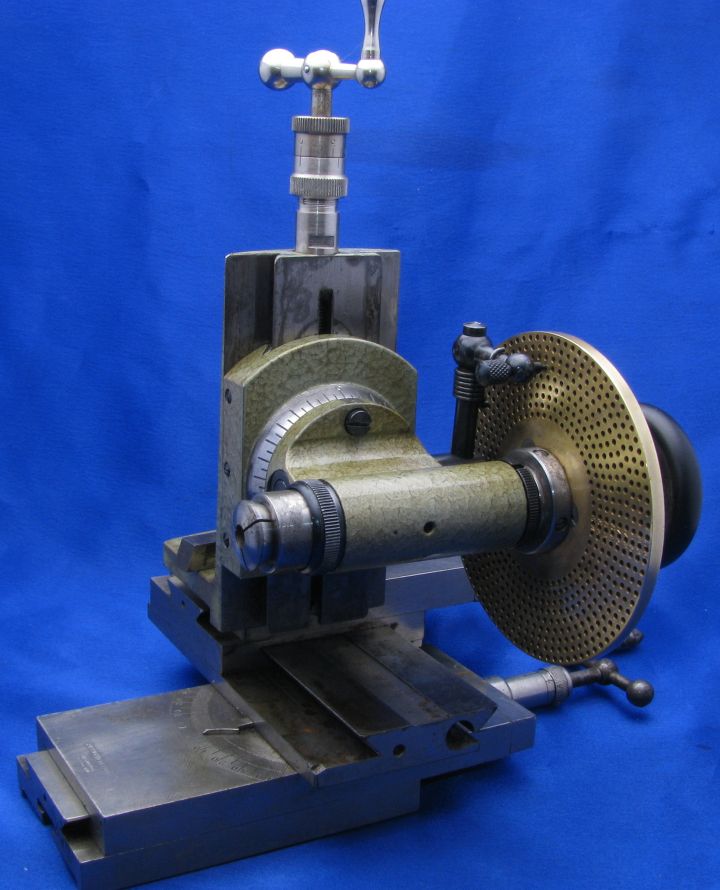

Just picked up a large quantity of gear cutters, plus attachments, milling head and not show but a set also for WW & PW gears. Never had cause to use these yet and a lot appear to be clock sizes. I see a they are marked from 0.55 M, 0.65m, 0,75M 0.85, & 0.95M, also marked are things like D9X, D1218X etc, The thick wire set are marked with 3 & numbers, also where do the button type cutter used. Can anyone explain the sizing etc.  | ||

|

| IHC Life Member Certified Watchmaker |

| |||

|

| IHC Life Member Certified Watchmaker |

| |||

|

Chris, you've got an absolute small fortune there in cutters! The numbers such as '0.55M' and '0.65M' etc refer to the 'Module' of the teeth to be cut. Rather than try to kill my brain explaining this, the following link will make things a bit clearer http://www.geocities.com/mvhw/gearing8.html The 'Button' type cutters you mention, would appear to be for cutting 'Recoil' type escape wheels as fitted to longcase and Fusee wall & Bracket clock movements etc. If you're getting into gear cutting, I would strongly recommend you get hold of a copy of Malcolm J.Wild's edition of 'Wheel & Pinion Cutting in Horology' http://www.amazon.com/Wheel-Pinion-Cutting-Horology-Historical/dp/1861262450 A superb book by a superb horologist, and highly recommended. Best regards John | ||||

|

| IHC Life Member Certified Watchmaker |

Thansk John, Will go and take a look at the links, I love buying tools like this when I see them I figure if I don't use them or in later years can always sell them and get my cash out again. The head looks good also, no doubt need more index plates, if I had a pulley could make the mill work also, more things to find  | |||

|

Chris, the M (module) you listed seem to me rather for clocks than for pocket', maybe the small cutters in the background are Modules for pinions and wheels for pocket (and wrist) watches... You did good to buy them....I wish I would have same luck...congrats ! rgds Enzo | ||||

|

| IHC Life Member Certified Watchmaker |

Here is a list I have just sorted them out in to groups, maybe someone can identify the to odd ball K & number ones at the bottom of list, Also a photo of the small set with what I take to be pocket or wrist watch cutters not a bad start to my gear cutting set up. I may get another lathe and just leave it set up for these M-0.55 6 7 8 10 12 W x 2 M-0.65 6 7 8 10 12 W x 2 M-0.65 9 x 2 10-11 12-13 55-134 x2 135 –X M-0.75 6 7 8 10 12 W M-0.85 7 8 9 10 12 W M-0.95 7 8 9 10 12 W M-0.55 7 8 x2 9 10-11 x2 12-13 14-16 17-20 21-25 26-34 35-54 55-134 x2 135 –rack x2 Odd balls below anyone tie them to a system K8 298 400687 400938 401081 401034 403929 K70 K173 531 K269 302 K305 K329 K391 K363 K464 K543 4011-70 K2619 K1299 K1941/10 K1567 K1633 K3576 K3570 K36-17/9 K3828 K3292 K3293 K4472/9 N29T.80-18 S C CH.08  | |||

|

Chris I echo what has already been said and I have used these cutters to cut clock wheels. They cost a fortune to buy, around £55, last time I checked. So now I send away to have my wheels cut which is far cheaper than buying a cutter thatg you may only use once. You can make your own cuttter for a one of job but the cutters you have are far superior. | ||||

|

p.s the small numbers (in brackets) i.e module .55 (6) are for pinions. For pinions you need a seperate cutter for each pinion if the number of leaves are different. For example to cut a six leaf pinion .55 module you need one cutter, For a seven leaf pinion .55 module you need another. Unlike a clock wheel where you can usually get away with one cutter for a range of teeth. Hope this helps. | ||||

|

| IHC Life Member Certified Watchmaker |

Hi Clive, So looking at the list I have above how much of a complete set do I have, would this be enough to meet most of your average needs as a clockmaker? I have seen the mill head go for about $600 alone without a index, but I need a drive pulley, no doubt I could make one of those I also have a Unimat 3 that I could turn it on. | |||

|

Chris If my memory serves me correctly module (for a wheel) is determined by the dia of the wheel (in mm) divided by the number of teeth. There is then slight rounding to get to the nearest cutter. I believe, again from memory, that a longcase wheel is typically around .75 module (but I would need to check in the workshop if its that important)but I don't think its far out. So what you have a good range of cutters but as your lowest module is .55 this would not go down to carriage clock size. I don't know about the odds that you list. The pinions are calculated slightly differently. But again you have a good range of pinion cutters listed. As to the dividing head this can be used to hold the wheel blank on a stub arbor. The cutter can be held in a stub arbour in the lathe. Hope this makes some sense. Kind regards. | ||||

|

| IHC Life Member Certified Watchmaker |

Thanks Clive, Seems like the odd ball cutters would be for smaller clocks so have a pretty comprehensive set, not to mention the red box set so another good set of tools to have, also picked up a very interesting jewelling set will post later on for fun by Swatchild.  | |||

|

WOW! Chris, I am just getting set-up for gear cutting and this is a real treasure trove! I received a quote from P.P. Thorton last Oct and it was 52.25 British pounds per cutter. Congratulations! | ||||

|

| IHC Life Member Certified Watchmaker |

Hi Bruce, I sold the M set off as dont see myself moving over to clocks, I still have the bag bottom right that I may sell off later and keep the small cutter set for PW/WW | |||

|

Has anyone been able to identify the "oddball" cutters? The "K" and 6 digit numbered ones? | ||||

|

"M" or Module is very easy to calculate you simply dividing the pitch diameter of the gear by the number of teeth of your gear you want to cut. Go to the Machinery's Handbook Page 922 for more information. | ||||

|

Oh! I forgot to comment on your Boley dividing head it is a very nice tool and a, must have, if you want to cut gears. I have one to match yours plus the Lathe and a complete box of goodies to go with it. I'll put this on my site someday so more folks can enjoy these tools and accessories. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide