| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Early Verge Fusee Escapement Problems

Early Verge Fusee Escapement Problems

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Early Verge Fusee Escapement Problems

Early Verge Fusee Escapement ProblemsGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

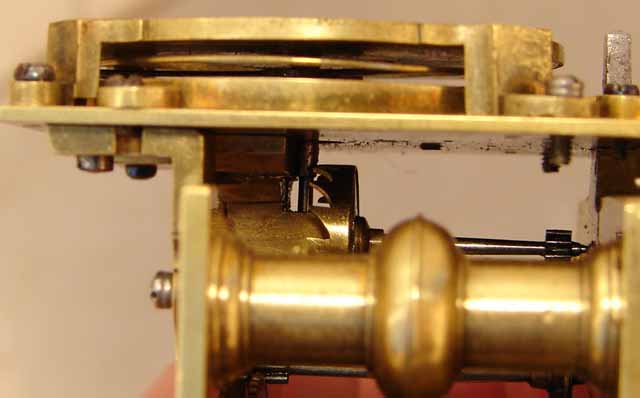

My repairman can’t get my clock to slow down enough to allow it to keep reasonable time. The Verge Fusee movement has been cleaned and will run down but is running very fast. He personally loves working on and collecting early fusee movements, but is having trouble with mine. If this makes sense, I have heard him make the following observations. 1) The teeth on the Crown Wheel appear to be backwards (curved the wrong way). 2) The Pallets appear to be too close together, approximately 15 degrees apart. 3) The Pallets appear to be too short to allow the Crown Wheel sufficient time to deliver enough power to the pallets. He told me the hairspring seems weak enough to allow the balance to swing as far as it is allowed, however the way it is set-up right now the Crown Wheel and Pallets are pretty much in constant contact. In the picture I’ll try to attach, the Crown Wheel is rotating toward you and the large balance wheel is shown at the top. The fast/slow adjustment is to the right of the balance wheel and the 4 ½ inch round silvered dial is attached on the right side of the movement in this picture. I would appreciate any suggestions as to what he should try. Also, I don’t know anything about the person’s name on the dial "C Backman, Stockholm". Sub-seconds at XII and date aperture just above the VI. Any help there would be appreciated as well.  | |||

|

Tom, Just popped in for a quick look and saw your cry for help, Your repairman needs to look at those pallets - 15 deg is way way too close, should be nearer 90 deg apart - think the ideal is around 95 deg give or take a couple, but this depends upon the movement. A wonder your clock runs at all to be honest, and no wonder it's fast!! My recollection here is mainly associated with watches, but the principle is the same. Can't comment on the direction of the teeth as it depends upon the situation of the train. Looks like it needs a good clean though! Best regards John | ||||

|

Tom, Another thought here re- the pallets; if they're too short, it could be the teeth had been working on the outer edges and have been filed away to get rid of the pits the wheel would have caused. It's then possible that the repairer concerned, twisted the staff to close up the pallet angles, as filing them short would have opened the angles excessively to the point they wouldn't lock on the wheel teeth. Can't think of any other way it could have happened unless incorrect replacements have been fitted at some point from a donor movement. It may be possible to solder thin plates of steel onto the remaining pallets to effect a repair - I believe some specialists use mainspring steel for this. Otherwise, you're into making a new staff / pallet assembly, and being generally hewn out of the solid, that's a serious repair job! John | ||||

|

Thanks John. I'll pass this on to him. I really like the clock, so I'd like to get it finished. Any idea who C Backman from Stockholm is? Thanks again, Tom | ||||

|

This is the dial to the clock. I just placed it on the movement for the picture. Does anyone have any information on the person named on the dial? Any help would be appreciated.  | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Early Verge Fusee Escapement Problems

Early Verge Fusee Escapement Problems

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Early Verge Fusee Escapement Problems

Early Verge Fusee Escapement Problems©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide