| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Visitor from the watch boards with a clock question

Visitor from the watch boards with a clock question

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Visitor from the watch boards with a clock question

Visitor from the watch boards with a clock questionPage 1 2

Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Hello, I recently bought a Verichron Regulator copy. I know this isn't collectible or anything but it looks good on the wall of my watch workshop so it would be nice if it worked. The pendulum swings for a few minutes and then stops. Is it safe to assume that is similar to a watch balance that won't swing probably meaning that my movement needs cleaning? All three springs are wound tight. Am I naieve thinking that my watch knowledge will help? or is it a completely different animal? If you think I can do it, let me ask my questions. Keep in mind that I don't have a lot invested in the clock but I don't want to break it either. If you think I should leave it alone and hand it over to a clockmaker please say so. First... how do I get the hands off? do I need a special tool? Secondly, Once I get the movement out, how do I clean it? The parts are too big for my ultrasonic. Must it be completely disassembled? This may all be covered in some clockmakers website so if it would be easier to direct me to a tutorial website please feel free to do so. Thanks for any and all help/advice. Regards, Jim | |||

|

| IHC President Life Member |

Jim, If it has three arbors one is time and the other two are strike. The minute hand will be held in place by either a tapered pin or a center nut that unscrews. My bet is you'll find the latter as that is most commonly used on newer clocks. Move slowly, consider taking pictures of important details. I usually remove the minute hand and then carefully pull on the hour hand with my thumb and fore-finger. Next, the dial is usually held in place by screws around the outside edge. Have a container handy for small parts. Once you remove the dial begin taking some serious pictures because that will be of a great to you help in reassembly. Posting some of those images in this topic will help to get more answers to the questions you will be bound to have once you are inside. Clocks are not really all that difficult to repair but some movements do have inherent problems that could cause difficulties for those who are unfamiliar with certain procedures. From your comments it sounds like the clock needs normal service but could also require some re-bushing, that's when it can get complicated. You might choose to send the entire movement to one of our guys for service. Let's see what others have to say. Lindell | |||

|

| IHC Member 659 |

Hi Jim First off I am not a clock repairman but there are a few things I can help you with. As Lindell said, how are the hands attached to the center arbor? If they are attached with the threaded nut, check to see if it is to tight. I have seen this keep a clock from running. You said when you swing the pendulum it runs for a few minutes. Is it really running? or just swinging back and forth. If running, you should hear a evenly spaced Tic Toc Tic Toc. If you hear the tic toc but not evenly spaced (at the far end of the swing) your clock may just be out of beat. If thats the case as the pendulum swings, slowly move the clock left to right on the wall to adjust the beat. You will hear the tic toc change. Thats just a start of things to check before tearing the movement down. WARNING!!! Don't go disassembling that movement untill you get some help with the springs!! There is a lot of energy stored in them and you can get cut, in the face, hands, arms when the energy is released uncontrolled. Gary | |||

|

If the movement happens to be a Hermle Westminster chime from 15-30 years ago it may be a lot less strain, stress, and aggravation to just buy a new movement. I understand that some of the older Hermele movements had plated pivots and when the plate wears off it's difficult to get them to run properly. i think there are advertisements in the NAWCC Mart for people who can supply new movements. I put two movements in cases I had bought separately 15-20 years ago and when they stopped running satisfactory I just bought new movements and had them both going again very soon with a minimum of trouble. | ||||

|

| IHC President Life Member |

If you need to follow John's recommendation, One source to check is Timesavers at 1-800-552-1520 or www.timesavers.com once the movement is confirmed. Another that comes to mind is Merrits at www.merritts.com on the internet. Let's see your movement Jim! | |||

|

Jim, You are in good hands with the people on this board. As was said, send some pictures of what you have. There is no reason you cannot service that clock yourself. You may even find yourself tempted to cross over and take in a few clock repairs in the future. You would likely have more success than I would have trying to repair a watch. We are looking forward to your pictures. Best Regards, Dick | ||||

|

Well... that sure is great response to my call for help. The good news is that the clock is running. Thanks to Gary, I found a spot where the beat is equal. Problem is the clock looks pretty silly tilted at at least a 5 degree angle. The amplitude is not great, but it has run for 2 hurs so far. How do I change the beat without rotating the clock? I assume there is some equialent to a roller jewel that I can move. I have the hands off and the screws out of the edge of the dial, but the dial won't budge. There must be something else holding it. I may still need to replace the movement since the amplitude is so weak, but I would like to give it a try first. The movement is Harris & Mallow West Germany. Is that one of the hopeless variety? Some of the pivots are caked up with dried grease. This clock does look to be from the early seventies. I appreciate all of the help and encouragement. Thanks and regards to all, Jim | ||||

|

Jim, I came to watches from clocks originally and I'm slowly moving back to them again. As you are unfamiliar with clocks, I would advise removing the pendulum, taking the movement out of the case and taking a good look at the back of it to familiarise yourself with how the pendulum is attached and beat adjusted. Would be as well anyway, as it clearly needs a good clean and maybe other work. The pendulum will be hung, and swings from, a flexible link, (Suspension Spring)which is essentially thin shim steel with brass blocks fixed at each end. The brass blocks will (probably) each have pins on them - one is fixed to hang the pendulum from, and one driven through it to hang it all from the back cock of the movement (this will probably be a pin needing driving out). The pallet arbor on which the escape wheel is fixed, will extend either into, or through the back cock of the clock (which acts as the rear bearing for the arbor) onto which is attached the crutch - this is a short rod hanging down at the back of the movement and which gives impulse to the pendulum from the escapement. This is the part you need to move to adjust the beat! Some higher end movements have this adjustment in the form of two knurled thumbscrews on the crutch, which removes any need to push the crutch manually. Some cheapo movements even actually need the crutch rod to be physically bent! It would help to know which form of crutch your clock escapement is fitted with. 'Usually', the crutch can be moved either left or right on the pallet arbor, against some form of friction collet - and it is by this means that 'Beat' of the clock can be adjusted. Imagine the clock laid face down, then view the pallet arbor as the balance staff, and the crutch collet as the hairspring collet, you will then understand that moving the crutch on the pallet arbor is just as you would a hairspring collet on a staff to bring a movement into beat! You will also find that the pendulum rod will be slipped into a cut-out in the crutch, or alternatively, have a slot formed in it in which a pin on the crutch locates, this is so it can be removed. Att the top of the pendulum rod, a hook is used to hang it from the suspension spring. The beat of the clock is adjusted by moving the crutch either left or right with the pendulum attached until the beat is even, but care is needed if you have to push the crutch manually, otherwise you run the risk of pushing the pendulum instead, and kinking or tearing the suspension spring that the pendulum swings on. You can either reach up the back of the movement for the crutch, or use a mirror to see what's there first. Ideally, set the clock vertical on the wall (front and sides) with a spirit level! You can always tell a clock owner who is unfamiliar with adjusting beat ........ the clocks are always 'leaning' causing the viewer in extreme examples, to actually cock their heads to one side to tell the time! Personally I don't buy any of this talk about changing movements at all, you may as well just go out and buy a new clock! Renewal may be a neccessary evil for the pro's - where time is of the essence and where folks won't cough up for their time repairing them, but for us amateur / hobbiests, all the fun is in the challenge of taking a cripple apart and getting it going again - otherwise why bother learing how to repair movements at all!. Have fun! John! | ||||

|

Thank you John... I now have the clock vertical and it has run for seteral hours with equal beat. Your instructions were superb. My options are somewhat limited as to the manner of repair, being on a budget. I was fortunate to find this gem in a thrift store for $15 so I'm inclined to clean and oil it myself. The dial is still holding fast and even though I've removed the screws, there seems to be something else holding it. Anyone have a suggestion? Once that is accomplished the photo requests will be filled post haste. I'm beginning to understand why you guys do this however. There is something about that tic toc tic toc... that touches the soul. Thanks again and regards, Jim | ||||

|

Thanks Jim, only too pleased to help. I'm an expert at working on a budget these days, so know just where you're coming from on that score! You don't need fancy gizmo's like bushing machines or even powered bench lathes etc, they do help, but they didn't exist a couple of centuries or more ago and plenty of old stuff is still ticking away virtually untouched! See what the movement needs first before running for the toolshop! Check the inside face of the front plate of the movement for additional nuts securing a falseplate which the dial may be mounted to! Sometimes thin alloy dials are fixed to a stiffer backplate, and it's not always obvious. You can't get at the dial fixings without first taking the falseplate off, then they can be seen. Best regards John | ||||

|

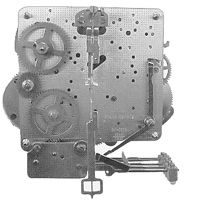

Here are the photos. | ||||

|

Movement | ||||

|

Movement Front | ||||

|

Rear | ||||

|

Hi all, I have it all re-assembled now and keeping time. Next question... how do I make the chimes work? Regards, Jim P.S. the dial was held on with double stick tape. | ||||

|

Jim, Great job thus far. Is there any movement in the strike or chime trains? The bars across the hammers are used to stop the hammers from hitting the rods. I am not sure from the picture, but it looks like they may be blocking the hammers from moving. Just move them out of the way. If there is no movement from the gear trains then we are at a whole other place for troubleshooting. Tom | ||||

|

Great Job Jim, looks good! From the photo's it looks as if the bar which should hold the hammer rods away from the chime rods is on the wrong side of the hammer rods, if so, the barrel which lifts the rods won't be able to move - it and thus the chime train will be locked! Effectively, they appear to holding the hammers against the chime rods and not away from them. The bar is used to manually lift the hammer rods away from the chime rods (ie: to stop the chime at night), but will still allow the chime barrel to rotate. Take it off and replace it under the hammer rods and see how it goes! John | ||||

|

| IHC Member 659 |

Hi Jim I am glad to have helped you in the begining but now your past my knowledge. Good Luck Gary | |||

|

| IHC President Life Member |

I think John found the problem. Of course the whole point of that hinged retainer is to keep the hammers from striking the chime rods when transporting the clock. Unless the retainer has been installed improperly it should be easy to simply move it so that full hammer motion is not restricted. Perhaps a closer image of the hammers might help in understanding this one better. Evidently they held the dial in place during assembly with "two-way" tape and then installed the screws. Over the years that tape can become very difficult to remove. I wonder how many of those dials have been damaged when overly-aggressive people tried to remove them. Good for you Jim in being patient with the dial removal procedure. By the way Jim, what is that information stamped on the movement? Lindell | |||

|

Betcha the movement is a Hermle. I have a bracket style clock with Linden on the dial and the movement is marked Cuckoo Clock Mfg. Co. Inc. The same numeric code appears on my clock, 341-020, as is on the clock in the post. In the clock I have the bar is between the bottom of the plates and the chime hammers, it's pushed up toward the plates for chiming. | ||||

|

| IHC President Life Member |

Thanks John, that makes sense. When fully assembled and the bar pushed away from the plates the hammers are then holding the rods down which would be for during transportation or to silence the chimes. Moving the bar upward toward the plates frees the hammers so they can then strike the rods thus allowing the clock to chime. | |||

|

It is indeed a Hermle movement. Frankenmuth has reconditioned movements with three different pendulum lengths for 59 bucks each. http://www.frankenmuthclock.com/garagesale.htm and R&M imports can supply new movements; they have a very lengthly list of models they can supply http://www.randmimports.com/mvmt.html | ||||

|

Hi Gary, Yes indeed. You helped get me started and I appreciate that very much. Thanks John & Tom... I have the aforementioned lever in the lower position now but still no chimes. I have noticed that the chime train is not moving. There seem to be lots of levers and cams that do move on the front of the movement but some don't move at all. I put pen marks on the chime drive train so I'll know if they ever budge. They havent moved so far. The movement is "Harris & Mallow - West Germany" Thanks again for all the help and encouragement. Regards, Jim | ||||

|

| IHC President Life Member |

Amazing what is out there, John! How they can offer a fully reconditioned movement at such a low price is remarkable. And the picture from Frankenmuth also helps show the chime bar positioning in greater detail. Crisp and clear...  | |||

|

O.K. Lindell, thanks for posting the picture. I now have the lever as pictured. I'm still not getting motion in the chime drive train however. The journey continues... Many thanks to all, Jim | ||||

|

Jim, Is the strike train working? When you wind the chime train does it wind tight? I am thinking that maybe there could be a broken spring, or the spring has come unhooked from the barrel. The other thought is that while being moved the strike or chime train has jammed mid cycle. Don't force anything. Move the train gently by hand backward a bit to see is that frees anything up. From your picture above it appears that the chime rack is not raised to where it should be at the end of it's cycle. Tom | ||||

|

Thanks Lindell, I'm not sure I haven't given Jim a bum steer on that bar over the rods though. On the photo it appears to be hard against the plates, and appearing to prevent the rods lifting, but from the clip you've posted, it appears to be well clear. BTW - does the movement have a strike also or just chimes, can't see a hammer for the strike although it does have a rack!? Jim, you are now entering Messrs Sod and Murphy's playgound (if it can go wrong it will) messing with (Westminster?) chimes ..... but with a bit of luck and low cunning you might just beat 'em Hope you're bald already, 'cos it'll save you a lot of angst sorting it out if it's a mess! You need to put the hands back on minus the dial, (hopefully in the right place), as it sounds like it's all out of sequence - forget the pendulum, the clock itself doesn't need to run as you'll be moving the hands manually. It could be as simple a problem as the snail on the front of the clock in the wrong place! Lead the hands around gently past the hour and quarters, then see what happens to the 'warning'. The 'warning', is when you would normally hear a click, whir and a clunk as the train is unlocked, moves a tad and braked - hence 'Warned' it's ready to chime!. Yup, sounds dumb, but not a lot of people know that! The 'warning' is unlocked about 5 minutes before the strike/chimes should run - at which point you should see the 'fly' rotate a tad and stop. The fly is the square brass plate which spins when the train runs - it's actually a governor or 'air brake' to stop the train overspeeding. At this point, the chime train is unlocked and free to run, but is prevented from doing so (usually) by a peg (possibly stopping the fly) which is lifted once the hour / quarter is reached, this peg is tripped by the mechanism on the front of the clock - if that's messed up, you'll need to work out how it's out of sequence. It's done this way so that the chime train runs at full speed immediately it's released, rather than steadily gathering momentum after being first unlocked - otherwise the chimes would emulate an old wind up gramaphone being cranked up! Lead the hands gently past each 1/4 and hour point but not too far to allow the train to run if it can, as you do so, look carefully to see what the mechanism is doing on the front to see what is stopping either the 'warning' or the brake releasing. I should add too, make sure that the chime train is actually free to start with. Usually you can see if there's any backlash movement in the train even if it's locked. Think I'm gonna need to climb into my loft and dig out an old westminster movement to look at, much easier to work these things out with the thing in your hands! I think most of mine are Hermele but these type movement generally work in a similar manner Good luck John | ||||

|

The chime lock should be between the bottom of the plates and the top side of the hammer rods; if it is below the hammers it may be just thick enough to keep the hammers from hitting the rods when they fall. There is very little clearance between the hammer rods/wires and the chime rods, The movement may be one of those nortorious Hermle products that were produced when the company was plating the pivots instead of polishing them. I replaced one I had that had a floating balance because the chime and strike trains quit running; it was intermittent at first but later became constant. There may have been a discussion of the problems with these movement some time ago here or on the NAWCC site. | ||||

|

Thank you John W. for the instructions. I have gone through the process and finally got a few chimes and strikes out of it, but it is intermittant to none. John A. Thank you for your observations. I must have one of the bogus movements because it is very intermittant and will surely get worse. I can see that the pinions are showing wear and surely the pivots are not any better. The hammers and rods are all out of allignment so even when it works it sounds rather "unique" All in all, I have a very pretty clock that runs and keeps time, but with a very low amplitude pendulum and it only runs in the exact center of the beat. Maybe I'll give the clock to my wife and buy her a rebuilt movement for her upcoming birthday. That wouldn't be much better than the new ironing board I got her last year. For some reason she didn't appreciate it. (just kidding, I needed some humor right about now) After all that, I think I'll hang it on the wall as-is, in the silent mode, and see how long it will last. I sure had some great coaching and support and even learned a few things about my clock. Three cheers to all!!! Hip Hip Hooray, Hip Hip Hooray, Hip Hip Hooray! Beat wishes gentlemen and many thanks, Jim | ||||

|

Followup: The clock is now on the wall running pretty well. It seems that when I clamped the hammers down, It put a load on the power train. When I let the hammers free, the pendulum started having more vigor. So I let the power down on the strikes and chimes springs and it is fine. At least it makes a decent wall clock even though the strikes and chimes are kaput. One more question. If the clock is running slow, do I lengthen the pendulum or shorten it? I should know that since I studied Engineering, but help me refresh my mind Thanks, Jim. | ||||

|

| IHC President Life Member |

Congratulations Jim To speed up shorten the pendulum, to slow lengthen it. | |||

|

Hello All, Would there be much difference between a Hermles 341-020 and a 341-020A? There is a NOS movement on eBay but it is the 341-020A (Mine is the 341-020)Westminster chimes. Is it worth the risk to buy it? or is there any risk at all? Thanks for any advice, Jim | ||||

|

The A appended to the model number may reflect a small difference in some details; I know the floating balance movements that I replaced had numbers with no alpha character where the new ones did. The model numbers were the same except for the alpha character. Having the winding arbors and hand shaft align properly with the holes in your dial and getting the correct pendulum length are the most important aspects. | ||||

|

| Powered by Social Strata | Page 1 2 |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Visitor from the watch boards with a clock question

Visitor from the watch boards with a clock question

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Visitor from the watch boards with a clock question

Visitor from the watch boards with a clock question©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide