| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Suspension Arm help

Suspension Arm help

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Suspension Arm help

Suspension Arm helpPage 1 2

Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Hi, I acquired a 1979 Ridgeway Grandfather clock and I was curious about the know/screw on the suspension arm. Do you turn this screw to adjust the tic tock?  | |||

|

| IHC Member 1541 |

Welcome to IHC185 John. I can't help you and if you get nothing here they do have a website Ridgeway Help Centre on upper right. | |||

|

I would guess that that thumb screw is there just to secure the pendulum. Without seeing the clock, I would guess that your clock has a self adjusting verge. You might take a look at this. It may or may not be close to what you have. Beat adjustment Dave T. Dave Turner | ||||

|

Again I’m new to this but I’m intrigued with the clock. I know the hook is for the spring which I broke taking this arm off. And the pins are for the pendulum. But dummy me I was messing with this screw and it has to be some kind of adjustment.  | ||||

|

A closer look at your first picture... I see a slot in the pendulum leader. Looks like the screw is to allow raising and lowering the pendulum bob to speed the clock up or slow it down. The "tick-tock" adjustment is referred to as setting the beat. That's the video I referred you to. If you broke the small suspension spring that this leader hangs on, it will need to be replaced. Dave Turner | ||||

|

Yeah I saw the video you shared and it was helpful but that darn screw had me guessing. haha | ||||

|

I bought a few replacement springs just in case. | ||||

|

| IHC Member 1725 |

John, I think on your Ridgeway Clock, they use two different movements. Just my guess, does your clock have a Urgos movement? As Dave pointed out to you above, I am almost positive that it has a self adjusting beat. This is accomplished by the strange teeth design of the escape wheel. I understand that you broke the suspension spring and this should be fairly easy to find and replace and it will have to be fixed for the clock to run. You need to be very careful with the escape wheel because they are very hard to find. The thumb screw at the bottom of the pendulum does raise and lower the bob and makes the clock run faster when you raise it and slower when it is lowered. I would suggest taking the pendulum off, turn it over and look at the back of it because there is kind of a trick to raising the pendulum but by looking at the back of it you will be able to figure it out. Hope this helps!! Tim | |||

|

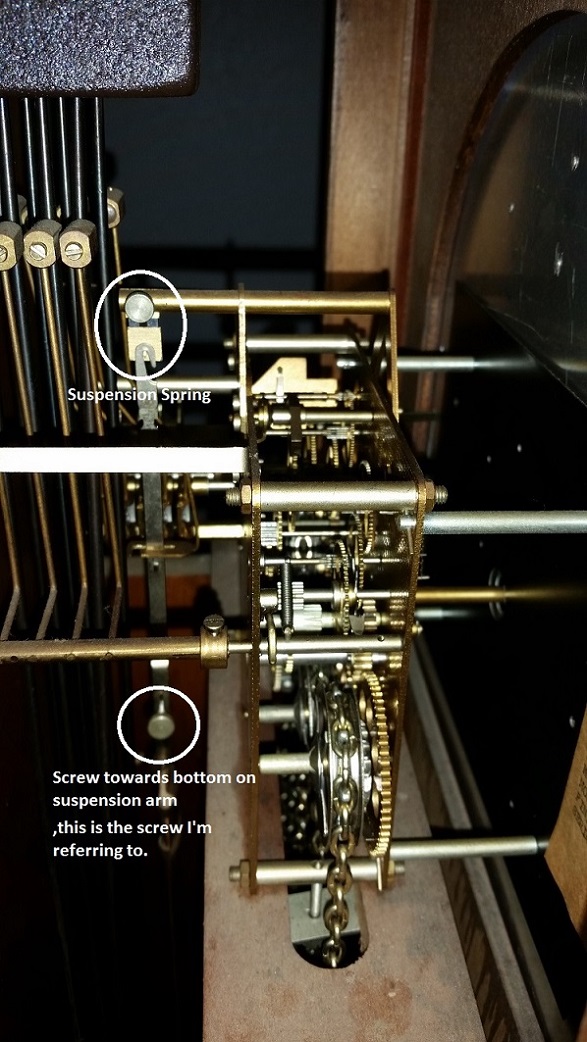

Thanks Tim, This pic shows the adjustment screw to which I didn't know what was for. I did know about the bottom nut on the pendulum. I’ve been having fun learning about this clock but I am major armature.  | ||||

|

Here is another pic  | ||||

|

| IHC Member 1725 |

John, I think the little thumb screw you are showing holds the suspension spring. If you look at the suspension spring it should have a small hole at the top, the thumb screw fits threw the spring snug just finger tight. If we can help anymore just let us know. Tim | |||

|

I posted another pic Tim, The screw at the bottom is what I'm trying to learn about.  | ||||

|

Another view  | ||||

|

I would have guessed Urgos too, but according to the stamping on the plates, this is a Hermles 451-053H. And the top two numbers are the date. 79 = 1979 vintage. And it does have the auto-beat adjustment. Evidently there was a change in the movements right after 1979, but your's appears to be the later model: Hermles 451-053H You haven't told us what's wrong with this clock, but so far everything looks okay, (that we can see). I think your suspension spring is okay too. Show us a picture of the pendulum. Dave Turner | ||||

|

I actually bought the clock at an estate auction for $95.00. The clock looks brand new. I have always wanted a grandfather clock for some reason. Apparranlty when I transported to my house I never disconnected the pendulum so the suspension spring broke. I know absolutleyy nothing about clocks but I’m getting better with the terminology. Haha Anyway I was confused so I paid a clock person to come to my house to see what was wrong. Well he let me know what I did wrong brining it to my house, installed a new suspension spring checked it out and told me everything look great for its age. He oiled it set the time and told me how to adjust the time if it runs to slow or fast. Well I noticed it was running anywhere between 2-5 minutes to slow so I would turn the screw on the bottom of the pendulum to the right and wait a day but it would not keep time because it was running to slow, so I starting cranking on the screw a lot then I noticed the knob towards the bottom the suspension arm so I turned that too. Now I’m sure I have it all messed up. I broke the suspension spring taking the suspension are off, didn’t realize how fragile that spring is. I ordered two more they should be in on Friday. That’s pretty much my story. My wife didn’t really mind me buying the clock when she saw it. But she doesn’t want me paying people to come to the house as it may not even be worth it. I’m a handy guy and I usually can fix anything I put my mind to it that’s why this clock is so intriguing to me. Now when you say self-adjusting what does that mean? Plus I’m at work so it would be later before I can send a pic of the pendulum. Hope nobody fell asleep reading this. | ||||

|

Nice story. Now we get the picture pretty much. For $95 you did well. A pendulum usually has a "rating nut" on the bottom end of the pendulum, which you can turn up or down to regulate the speed. The one shown in your picture might serve the same purpose, but I've never seen one like that. There's a vertical slot in that piece which would also allow up and down movement. As for the auto beat... if the clock does not tick-tock evenly, as you listen to it, then you can move the leader, the part the pendulum hangs on, to the left or right by applying light pressure, and it will adjust the verge at the top which rides on the escape wheel, to allow even drops and locks on both sides of the wheel. That's where the sound comes from. You'll get there! Dave Turner | ||||

|

Thanks Dave, So this pic is what they call the leader then. This is what the pendulum hangs on. But the knob on the leader is also an adjustment?  | ||||

|

It appears to be, but I'm not sure. When you get home show us a picture of the top end of the pendulum and how it fits in here. Dave Turner | ||||

|

| IHC Member 1725 |

John, Your clock is well worth what you paid. That clock when new sold for around $2000.00 to 2500.00, and it looks to be in great shape. We all have broken a suspension spring at one time or another. Now that we know more, we would like to know if the weights are in their correct places? Look at the bottom of each weight, there should be a letter denoting their proper place. The weight of each weight is a little different, so facing your clock, L-left, C-center, and R-right. If the wrong weight is in the center the clock will not keep time no matter what you do. Tim | |||

|

Pic 1  | ||||

|

Pic 2  | ||||

|

Tim, I'm having problems seeing any marks. Can I go by weight? | ||||

|

I'm not Tim, but chances are your weights originally had stickers, if they aren't marked. And chances are, the heaviest weight goes on the right hand side looking from the front, and the other two most likely weigh the same. If not put the lightest one on the left. Not absolute, but that's where I'd start. As for the thumb screw in question... I think it has no bearing on adjustments. It just holds the pendulum. Dave Turner | ||||

|

| IHC Member 1725 |

John, Just adding to Dave's post. I am absolutely positive the lightest weight goes on the left side. This creates a "slow gong" sound when your clock strikes on the hour. Now the other two weights will be about the same weight as each other with one slightly heavier. The one being heavier should go on the right, this creates the faster speed of the hammers when the clock strikes the quarter hour, and of course the last one goes in the center for the time train. Once you have these right, I would advise you to label the weights for future reference. Welcome aboard IHC185, Tim | |||

|

| Life Member |

Didn't read all the posts, so please excuse me if I answer some questions that have already been addressed. First, as to weights: The heaviest weight always goes on the train that requires the most power. If you have a three train clock (time, strike, and chime), the chime train requires the most power. The time train always requires the least, and therefore takes the lightest weight. The thumb screw on the leader is to adjust the beat. Set the clock up so that the seat board (the board the clock movement is attached to) is level, both side to side and front to back. Then hang the pendulum, and listen to the beat. The tick and tock should be even. If they are not, that is where adjusting that thumb screw comes in. Turn it one half a turn at a time, and give the clock a minute or so to "settle" in.If you cannot get the beat even by adjusting the beat setting screw (which is what that thumb screw is called) then there is a problem with either the leader or the suspension spring. One or both of them may be bent. It is also possible that the "chops (the slotted pin that the suspension spring is attached to) are not vertical. That is least likely, but can sometimes be the case, if the clock was "repaired" by someone who did not know what he or she was doing. First, be certain that the suspension spring and leader are perfectly straight, before trying to adjust the mounting block or chops. If the suspension spring is kinked, there is nothin that can be done but to replace it with a new one. IF the leader is bent, it can be carefully and JUDICIOUSLY straightened. IF you need new parts, you will find a series of numbers stamped somewhere on the back movement plate. Using those numbers, search for one of the clock material supply houses on line, and order the replacement part. If you are unsure what part to order, most houses have very knowledgeable and helpful staff. Call them and explain your situation on the phone. Forgot to mention. Judging from your photographs, it appears you have a one second pendulum. Once you have the clock in beat, you can then adjust the rate by moving the pendulum up or down with the nut at the bottom (Called a rating nut.) Also, your photographs do not show it, but there should be a thumb screw with a straight turned portion, that goes through the hole in the upper end of the suspension spring. That screw will only go in the mounting block from one side, and must be tightened finger tight, but tight enough that the suspension spring cannot "rattle" in the slot. | |||

|

| IHC Member 1555 |

David is right about the most weight to the chime side John, weights for your model (Hermle 451) if I read the post correctly should go with the heaviest ( I think 6.6 lb) to the chime side. The other two weights should be the same at I think 4.7 lb and go on the time & strike trains. This info is for a normal pendulum and bob, if you are running a later "lyre" pendulum or have a second hand on the movement it is different again. | |||

|

Thank you,Thank You all for your help. | ||||

|

| Life Member |

Forgot to mention: Tall clocks are notoriously top heavy when fully wound. Particularly if you have small children or pets in the house, I recommend it be attached to the wall after it is leveled. | |||

|

| IHC Member 1725 |

John, I think you said you was hoping for your suspension spring Friday. After looking back at your great photo, January 11, 15:14 It might be a good ideal to straighten the bend in the rod were the thumb screw is and start fresh. Then use your beat regulator knob IF NEEDED. Take your time and good luck!!! Tim | |||

|

| IHC Member 1725 |

John, Just another tip. Is your clock capable of playing several different melodies such as Westminster etc. If so, I am sure there is a "warning" in the owners manual {don't know if you have one} to NEVER change the tune switch until it is finished chiming. Doing so could cause something to bend or break. Tim | |||

|

| Life Member |

Rim, I don't mean to be disagreeable, but those two bends nion the leader appear to me from the photos to be correct. The leader is made with a offset, so that when in beat, the suspension point is nearly in line vertically with the suspension spring. Of course, since there is one offset, there has to be a second one to counteract that. If you look closely, you will see that one is greater than the other,. That is so the beat adjustment will bring the two ends more nearly in line. | |||

|

| IHC Member 1725 |

I see what your talking about now David. John said he "cranked" on the knob in a early post. If he backs the knob out do you have to bend the leader back some, or does it have the spring "worked" in the bend? Not real sure how that works. Thanks for the correction. Tim | |||

|

| Life Member |

It will move back on its own. The portion of the leader that the adjustment screw bears against is spring steel. He should start with the beat adjustment screw about halfway in, so he has equal adjustment in either direction.  | |||

|

| Powered by Social Strata | Page 1 2 |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide