| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Cute Travel Clock

Cute Travel Clock

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Cute Travel Clock

Cute Travel ClockGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

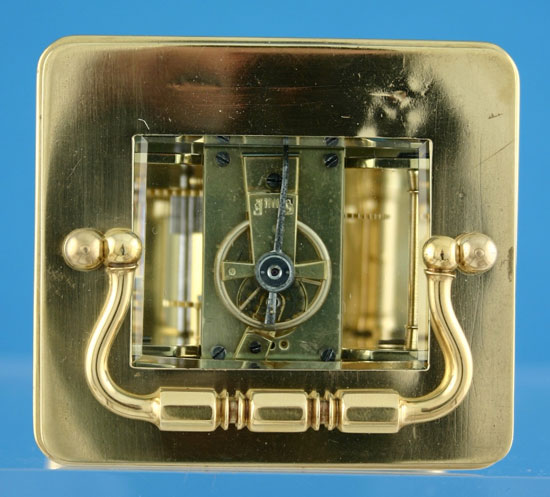

I purchased this little clock recently. I assume it is a French travel clock. It measures 1-3/4 inch wide, 1-1/2 inch deep, and 2-3/8 inches tall. It has a pocketwatch type balance wheel, beveled glass, heavy brass enclosure. It is stamped "Made in France" and "55". Has anyone ever seen one like this before? Any idea how old it is? Value? Thanks  | |||

|

Mark French (that wasn the easy part) 1890 and the following picture reads ' polishing ' Regards, Gerald  | ||||

|

| ||||

|

All done. Runs great. Had to replace the upper pallet fork bridge jewel and straighten the safety pin.  | ||||

|

Great job! Mike | ||||

|

| IHC President Life Member |

Really beautiful workmanship Mark! The "before-and-after" pictures tell a great story. Lindell | |||

|

Thanks. The glass panels rattle a bit. Would you think some crystal cement would be in order or leave it alone? | ||||

|

Very Nice job Mark, and most folks have no idea just how much work goes into polishing one of these to get it back to looking that way. I've done a few of these and always relieved to a point when they're done. I've one here to start that I bought last weekend. They're more commonly called Carriage clocks, mostly French, and often found with a London retailer's name on the dial and movement, some with Parisian addresses. The escapement type is a 'Platform' escapement, which are cylinders on the earlier types that commonly get swapped for lever types when busted. Your clock is sort of between a traditional type and a 'Bayard' produced by Duverdry and Bloquel, which also has a winding key attached. Traditional clocks use a double ended key - for winding and setting. I was a bit thrown at first when you mentioned changing the pallet fork jewel, as I noticed in the first shot, it still has it's cylinder escapement. Did you change the platform because the pivots or cylinder were broken? If you can repair the cylinder platform and refit that, I'd recommend you do, because it will keep the originality and value of the clock, whereas the lever platform is not correct for its era, and reduces the value for a collector. It's a common enough swap, and better than a non working clock, but do repair and refit the original cylinder platform if you can. Often these vanish without trace and cost a small fortune to buy a working replacement even if you can find one - often as much as a clock is worth. Certainly keep the original platform with the clock anyway! The glass panels can be sealed discretely with clear silicone sealer ok, which is flexible and will allow for some expansion and contraction of the case. Cement can be used if unhappy with a modern type goo to stop them rattling, but it will be rigid and fracture. More importantly, sealing the glasses helps cut down the dust getting into the case and movement. It will also help prevent the fragile sharp corners of the bevel edged glasses getting chipped and flaked. John | ||||

|

John: Thanks for the info. I replaced the jewel because it was cracked and it looked like it had a ragged edge, so I didn't want to chew-up a pivot. I would like to seal the glass panels to keep the dust infiltration down. Where can you get silocone sealant with a fine tip applicator? | ||||

|

Here is an odd twist. The clock was running great for about a week then started stopping. I figured a piece of dirt might have gotten in. So I wrapped it with masking tape to keep the glass panels in place and took the clock out of the case. Couldn't see any dirt but blew it out anyway. Let it run a day under a bowl - ran great. Put it back together and it stopped. Now, the screws on the bottom plate do not exactly lineup with the case. When I attach the case to the mounting plate, it stops. Could there be torque transfered from the case to the internals to cause the movement to stop? | ||||

|

Mark, Apologies, I missed your question about silicone. Don't know what stores you have near you, but plumber's merchants or DIY sheds are favourites. I generally squeeze a bead onto some card and then apply thinly onto the sections with a small applicator made with whatever comes to hand. Awful stuff to deal with like this, and a pig to get off anything, so not a good idea to put it on the glass itself because you have to handle it by the edges. Also, because of the acidic content in silicone, (self cures and smells of vinegar), leave the movement out of the case until fully cured. A good and maybe better alternative is to use decorator's caulk, this is generally water soluble, cleans up well and seals ok, the only rub being colour - it'll be white or tinted. Strange that it ran a week then stopped, but it's very possible that the frame has shifted when you moved it at some point, so when you tighten the movement mounting screws, the clock plates are being mis-aligned enough to make the train bind. Expansion and contraction of all the brass parts could also have caused the case to move around some too. The screw holes should all line up good, so if anything's not square there, it will cause a twist if the screws bind going in. What you could try, is mount the movement with the case pillar screws slackened, then nip them up again when the movement is back in and running ok. The plates should sit quite square on the mounting with no gaps, so any gaps at the corners will place a twist on the plates. Make sure also that looking down on the case top plate, that it's square with the bottom one too - sometimes they can get twisted out of line on the pillars, which will strain things. I know all too well what a fiddle these things can be to get right. Just so folks get an idea what a pain these can be to put together again, I've added a photo of a typical case assembly in bits. This is of a similar clock by Duverdry and Bloquel I restored some years ago. John  | ||||

|

| IHC Life Member Moderator |

We also have a couple crystal regulators on the bench at the present. It is an exercise in presenting the parts in the exact sequence for the assembly. I have another unit that was running very nicely right after a complete service,and after 3 weeks it refuses to run very long. Awww, no goes the detective work again. Oh how we love our jobs! So just have lots of patience Mark, you'll get it going again. BTW do you have a shop in town? I have a brother Bill, living just on the west side of Hartville and a bit north by the old RR bed. Moses | |||

|

Thin strips of leather works very well keeping the glass from rattling. Bob | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide