| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Fitting Clock Hands

Fitting Clock Hands

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Fitting Clock Hands

Fitting Clock HandsGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

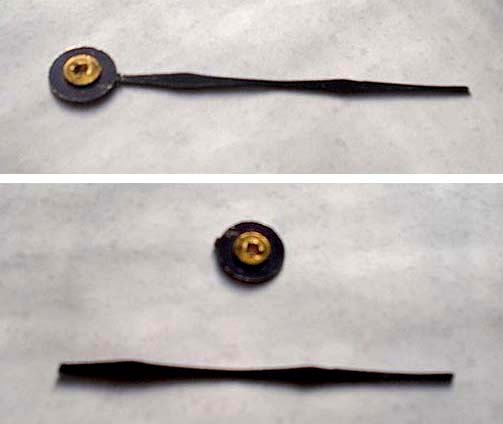

I want to put a new hour hand on a Kienzle Westminster mantle clock. I found one that looks similar. It has a square hole and needs a brass bushing. Can someone help me with the procedure for bushing the new hand, as well as where to purchase the correct brass bushings? Thank you, Nelson | |||

|

Nelson I believe the bushing will have to be made. can you post pictures. bill@fixoclox | ||||

|

pictures.  | ||||

|

Nelson Since you have the broken hand take the bushing out by cutting the hand. When it is out measure it. On the new hand carefully broach it out to fit the bushing.Does the clock strike if so you will need to index the bushing to the hand before peening it.Lightly peen it with a ball peen hammer then index it then make the peen a little tighter. Give it a try you have nothing to loose at this point. Also if the new hand is steel you could solder it. Good luck. bill@fixoclox | ||||

|

| Honorary Life Member Internet Consultant |

I would try to braze the old hand, or find a new one at some place like Timesavers. If you can't find a similar one, settle for one with a lot more "meat" on it and file it down to the desired shape and size. A word about the bushing: There is a reason why the hour hand is bushed instead of just having a square hole. When assembling a time train, it can be very difficult to get everything indexed so that the hour hand lines up perfectly. The solution is not to try. Just use a bushing. Observe the hour hand and see where it is when the hour begins to strike, noting how far off it is and in which direction. Now remove the hand. You can insert a special tool into the square hole, or just use the square tang of a file. Apply some torque and the bushing will give. It's meant to slip under pressure. That's your adjustment. If you braze it, add some metal to the back side for strength. Be careful not to braze the bushing in place. To hold the assembly in position for brazing, use some iron wire that's been coated in graphite by a plain old pencil. A thin coating will do. The graphite acts as a resist and keeps the wire from sticking. (Unless it gets covered in braze, which is fine on the back side.) If you end up with a huge blob, just file off the excess. I use silver solder and a flux called "handy flux". It's water based, so if it dries out in the blue and white jar just add water and mix. I use an oxy-propane torch which is available at hardware stores. It produces a superb needle point flame. The metal must be clean and bright, and it helps to "tin" it first with a thin layer of silver solder. My brazing surface it a square tile of natural slate. It came from a tile store. I intended to pay for it, but they insisted that it was a sample. Hope that helps. Best, Tom | |||

|

Thank you Tom, I will take your advice and braze it. The reason the hand broke was that the bushing was stuck and just would not move no matter what. I forced it and the thin part of the hand's stem broke off. Nelson Queens, NY | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide