| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Elliott ships clock.

Elliott ships clock.

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Clocks, Including 400-Day Discussions

Clocks, Including 400-Day Discussions  Elliott ships clock.

Elliott ships clock.Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

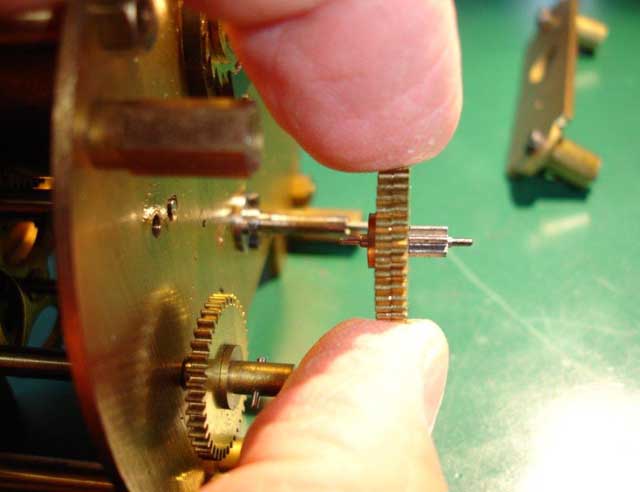

Hi folks. I am currently restoring a Elliott ships clock which I purchased on E-Bay. I found a strange cog which is split in two lengthwise and sprung loaded so that each half of the cog can move a little under spring pressure?.....I have included a picture and was wondering what on earth this sprung cog does in the movement?. As you can tell, I am a bit of a novice at the moment but I am learning all the time!.  | |||

|

HI Stephen, the the splitting of a gear in two halves that are then spring loaded against each other and the meshig pinion, is usually done to remove any possible play between the gear and the pinion. | ||||

|

Thanks Peter. As the clock has a sweeping second hand I presume this method allows the hand to turn smoothly?. Kind regards, Steve. | ||||

|

HI Steve, Yes, this is the equivalent of the friction leaf spring used on center second pinions watches such 4992B and BWR's to ensure a smooth, unidirectional movement of the second hand. There is a good reason for the "split gear" system used in your watch. This would permit the "pinching" force between the two gears to be set very accurately on a test jig before assembly, thus avoiding any further adjustement. Regards, Peter | ||||

|

Thanks Peter. I have re-assembled the clock but this time, I have inserted this cog sprung loaded by a couple of teeth so that it is under spring pressure. I presume this is correct. Steve. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide