| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  German "Maler" matel clock

German "Maler" matel clock

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  German "Maler" matel clock

German "Maler" matel clockGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

I have a mantel clock from Germany with the name Maler on the face. It has Westminster chimes and strikes every 1/4 hour progressively playing more of the chime at every 1/4 hour until playing the entire bells then chiming the hour. The pendelum swings and the escapement moves, all the gears move, but the minute hand does not advance and neither does the hour hand. I can manually advance them and the bells all work. What do I need to fix? | |||

|

Derek, Welcome to IHC185, From what you describe, it sounds as if the hands and motion work aren't being nipped properly by either a nut or a pin which you should see on the arbour at centre of the hands. This would allow the shaft to rotate but not drive the motionwork. There should also be a dished washer at the back of the hour wheel, which exerts pressure on the motionwork when either the nut is tightened or the pin is inserted. It's lightly compressed by the nut or pin to create a frictional locking that can be over ridden to set the hands, and yet drive the hands from the train. If there's a small nut, see if it's loose and try nipping that up a touch - but not too much. If it's a pin, see if it's loose or if there's any back and forward 'slop' when you pull and push the hands. If there is some movement, the dished washer will be either broken or sprained and not locking the motionwork to the drive shaft. These washers often take the form of a thin brass 'triangle' with the tips of the arms exerting pressure on the back of the hour wheel. If sprained, they lose pressure, but can be revived by bending outwards slightly. If broken, you'll have to make or find a replacement. Sometimes the pressure is exerted by a dome washer which fits behind the nut or pin, depends what type the movement is that you've got. The chimes etc still work because you are manually driving the motionwork which will trip all the strike / chime mechanism normally. All you've lost is drive from the train to the motionwork. You will probably have to remove the movement to take the dial off and check the dished washer at the back of the motionwork if yours is that type. Hope this makes sense. Best regards John | ||||

|

Dear, Mr. Woolsey, Thank you so much for your response. The minute hand rests on a square peg at the end of the drive shaft. I don't think the front nut actually maintains friction. The hour hand rests on a bushing that encases the drive shaft and is turned by a secondary set of gears. There is about a 1/16 inch slop for the bushing when the nut is tightened. There is a friction washer with three "arms" that emanate from the center. It is tight enough to the train that it moves in synch with the gears. I tried placing a washer between the nut and minute hand to see if that helped with no results. I did the same between the min and hour hands. This removed the slop in the hour hand bushing, but did not accomplish a fix. I've put a picture of the clock hands. I will post a separate showing the spring washer. The only markings I can find on the clock is the number 1219 on the back.  | ||||

|

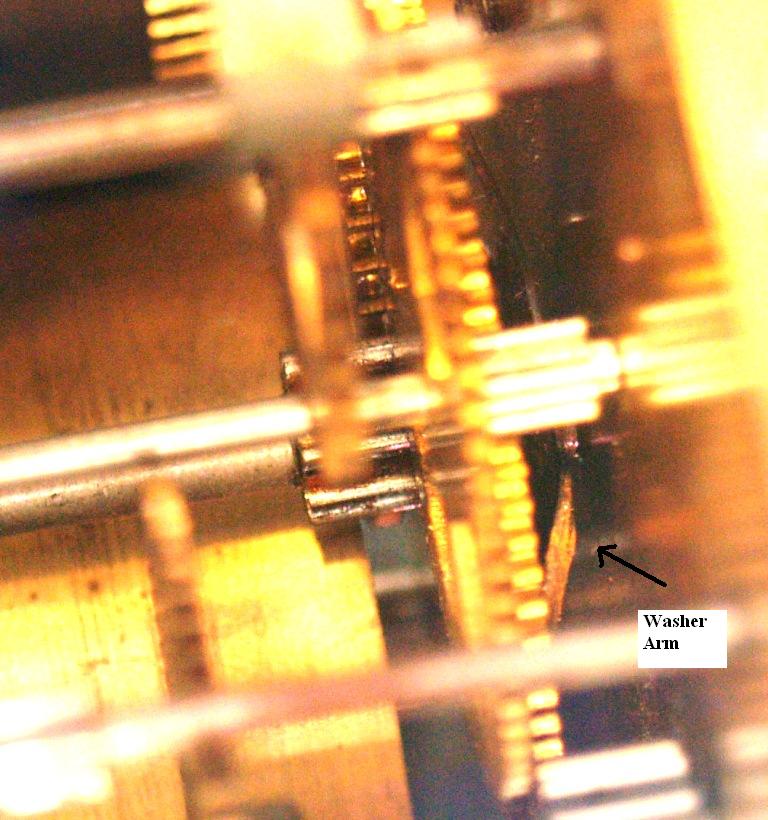

Picture of spring washer  | ||||

|

Hmmmmm, I'll have to dig one of my old movements out and take a look, I wrote my checks from memory, so may have missed something. What you could do, is let down the mainspring on the time side, then take off the back cock, then lift out the pallet arbour and crutch (pallets will be attached). If you give the train a light wind again, this will allow the train to freewheel so you can observe what's happening - or not as the case may be. I had a similar problem with an old Enfield type mantle clock, and the motionwork had shifted somehow sufficient for the gears not to mesh. The clock was ticking away, but the hands not moving. Can't for the life of me recall what the exact fault or fix was, but it was easy. I'll come back with some ideas when I've pawed a movement. Best regards John | ||||

|

Just thinking, do the hands when manually moved, turn too easy? IF so, see if there is a driven pinion on the center shaft. Is it loose, split? | ||||

|

Dear Mr. Cain, You are partially correct. I finally got the nerve to take the movement apart. There is a "dished" washer with four arms that reach off of it to provide friction against the drive wheel, and a brass bushing that you press onto the cannon pinion to hold that washer against the wheel. I have surmised that this bushing is worn, and/or the pinion is worn to the point that they will not keep enough friction to drive the hands. So the question is now, where can I possibly find a new part? I am not without skills, but these parts are far too small for me to mill. | ||||

|

GREETINGS DEREK, YOU HAVE TO REMOVE THE 4 LEGGED RETENTION SPRING AND GENTLY BEND EACH LEG DOWN A BIT WHICH WILL GIVE YOU MORE HEIGHT AND COSEQUENTLY MORE TENSION.IF IT IS A BUSHING THAT HOLDS THE SPRING YOU SHOULD CHANGE THAT AND ADD A PIN THROUGH THE SHAFT A SMALL PIN. WITH THE SPRING IN ITS FREE STATE AND RESTING ON THE BACK OF THE GEAR MARK THE SHAFT AND THEN DRILL A SMALL HOLE ON CENTER 1/16 OF AN INCH BELOW THE MARK AND INSTALL THE SPRING AND INSERT THE PIN. THAT WILL SOLVE YOUR PROBLEM. IF YOU FEEL YOU NEED A DIFFERENT SPRING LET ME KNOW I HAVE SEVERAL. GOOD LUCK. EDDIE | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide