| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  Set Thomas mod 124-hands stop, clock keeps running

Set Thomas mod 124-hands stop, clock keeps running

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  Set Thomas mod 124-hands stop, clock keeps running

Set Thomas mod 124-hands stop, clock keeps runningRelated Content: Clocks, Including 400-Day Discussions

Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Clock runs fine, hands stop at 5 mins before the hour, yet the clock continues to run an the 1/4, 1/2 and 3/4 chime will strike. All this time the hands have stopped at 5 till the hour. Move the hands 2-3 mins in position and it will run fine till it gets back to 5 till the hour. I am watchmaker not a clock man, trying to solve this delimma for a friend....any ideas? | |||

|

Steve, I'm not familiar with the type, but it sounds like it may be a 3x train time/chime/strike type movement. Let me know if I'm wrong! Anyway, it sounds as if the motionwork is stalling when reaching the 'warning' stage of the hour chime stage - this is where the 'Hour strike' train is released and stopped prior to it being finally released when the motionwork trips it on the hour. (Usually you will hear a clunk when the rack drops, and a whirring noise as the gears run a short distance then lock) This allows the hour strike train to run quickly to full operating speed when released. If you check the minute hand arbor, it's probable that the hand will move very easily, there should be some friction there. On that minute hand shaft somewhere, the gear that drives it actually 'freewheels', but will have a dished washer or 'spider' bearing on it, which is held under compression by a taper pin pushed through the shaft. The amount of pressure the spider bears on the gear, effectively locks both the arbor and the gear together and allows the train to run the hands and motionwork, yet also allows sufficient slip for the hands to be set without forcing the escapement to run faster. If that washer (or spider) is weak, it will allow the minute hand arbor to slip causing the hands and motionwork Not to be driven if it comes against an obstacle (the rack etc) - but the movement will still run. The quarters run on a different locking device on the chime train, so won't be affected by the rack which needs to be released to govern the number of hour strikes. That washer or spider needs either replacing if broken, or its arms bending to add more friction to the train! Hope this makes sense! Best regards John | ||||

|

Thank You so much ,that makes perfect sense. I see that the center wheel shaft is a 2 piece shaft, how do I get to this spider gear? | ||||

|

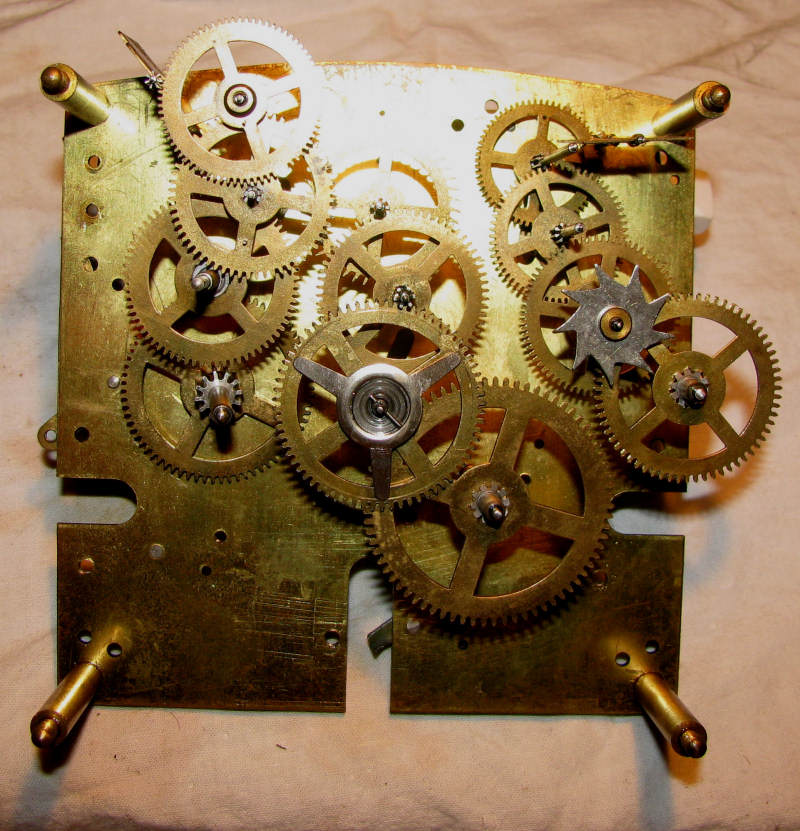

Steve, You really need to split the plates to get the train wheels out. Once you get that arbor out with the gear fitted, you can then see what the problem is with the spider. If it turns very easily, that's where the problem is. You might be able to fiddle around with the pin etc to release the spider with the movement built up, but if it's damaged you'll still have to split the plates to repair it. If you hold the minute arbor and push the wheel,(with the pallets out to allow the time train to freewheel) it shouldn't budge too easily, so you can check this easily enough before you dig deep. The photo attached is of a 3 train Westminster movement from a 20's Granddaughter clock, the spider and pin arrangement can be seen on the central wheel. John  | ||||

|

Quick footnote Steve, Take Plenty of digital photo's before you strip the movement, Especially of the chime/strike lever arrangement and the position of any cams etc, it'll make building up the movement soooooo much easier! John | ||||

|

Thanks so much John, you have saved me much time and effort. I never really wanted to do clocks but I find them much more interesting than I used to, I turn down at least 1 clock a week, nobody near here does trade work (nobody that I would refer a customer to anyway). If you could pick a good book on clocks, what would it be? thanks...Steve | ||||

|

Anytime Steve, always pleased to help if possible! I'm finding myself moving more and more onto clocks too, least of all because I can see what I'm working on! But you're right, they are very interesting - and quite challenging at times. Can't say any particular book comes to mind for clock repairing, as each of them offers something another doesn't. Most of my repair knowledge came from my BHI study notes initially. A few here to consider though, and all of them are on my bookshelf! Anthony J. Whitten's book 'Repairing Old Clocks and Watches' (ISBN 719801907) is an excellent one to kick off with, and gives good diagrams for bushing plates and repairing pivots, through to repairing fusee chains. Even covers making tools etc! If you're just starting out with clocks, this one is probably as good a choice as any! Anything written by Donald De Carle, or W.J.Gazeley is very good too! 'Striking and Chiming Clocks' by Eric Smith (ISBN 0715303708) is good and covers a wide range of the more complicated movements, also loads of diagrams of chime and strike work! Also by the same author, Clocks & Clock Repairing' (ISBN 0718827082) I think there's a book by Conover that covers American clocks, but I've never read it as I only really get my hands on European stuff. Do get hold of a book on escapements though, if you're moving into clocks you'll need one! W.J.Gazeley's 'Clock and Watch Escapements' (ISBN 070904738X) is excellent! One of the main areas of any clock that comes to grief and need major repairs is the escapement! Folks tend to shift clocks around without taking out the pendulum, and on a springer, that's deadly, and how folks manage to shift a 'long case' with a pair of stonking great cast iron weights in place beats me .... but they do it! The ensuing mayhem caused by a pendulum thrashing around forcing the pallets against the escape wheel teeth, invariably requires either repairs to teeth or a replacement wheel - which means subsequent reworking of the pallets to get the drops etc right - Or making a new pallet blank! One tip I would give you, is check for books on eBay, but also check Amazon, prices there are often far cheaper than any eBay BIN offering, as more and more used books are being offered - although you may get lucky with a low bid on eBay! Enjoy your clock repairing! Best regards John | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  Set Thomas mod 124-hands stop, clock keeps running

Set Thomas mod 124-hands stop, clock keeps running

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  Set Thomas mod 124-hands stop, clock keeps running

Set Thomas mod 124-hands stop, clock keeps running©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide