| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Horological Tools, Books and Miscellaneous

Horological Tools, Books and Miscellaneous  Rose Engine

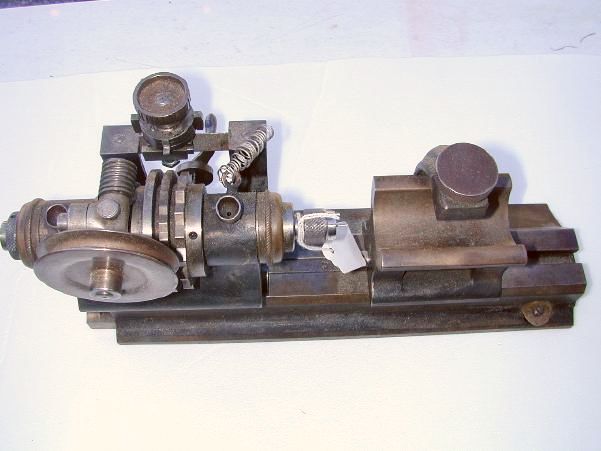

Rose Engine

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Horological Tools, Books and Miscellaneous

Horological Tools, Books and Miscellaneous  Rose Engine

Rose EngineGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

I foundd this and some other sites on google, including one in which someone had made a rose engine (a type of turning machine) that he used. It gives the parts and their relative location on the machine, but I didn't have time to read the page. There were other interesting pages. Plus this one, whihc has quite a bit of information: http://www.pledge.co.uk/ Jessica (ps haven't had time to investigate) I wish I could learn to use these things, but I can't yet understand the vocabulary, much less exactly how they work.. | |||

|

| Life Achievement Military Expert |

My first introduction to this art form was through a reprint of a book by Holtzapfel called, COMPLEX OR ORNAMENTAL TURNING. The original publication was part of a set printed in England in the 1880's. Holtzapfel was a lathe maker and pioner in the production of such machines which are also called, "Rose engine lathes." Holtzapfel's machines were not necessarily made to ornament watch plates, though I suppose they could be set-up to do so. These machines were extensively used to make the plates for printing bank notes. The complex damaskeening of watch plates was done with similar machines to those of Holtzapfel. Some of the more simple forms of ornamental turning can be done with a watchmaker's lathe fitted with a pivot polisher and some form of headstock index. The pivot polisher is often used in this way to ornament spring barrels and the winding wheels of a watch; such work is known as "snailing" or "spotting." For snailing, spotting and damaskeening, a little revolving wheel (lap) is covered in dimond dust. This lap is moved across the watch part cutting a pattern as it goes along. How the little lap is moved accross the part is the trick. Different machine opperators had different patterns. In some cases damaskeening was a true art form practiced by artists of whom little is known today. Best regards, Greg | |||

|

Very interesting. I don't know how to use a lathe; from looking at pictures, I've gathered a vague idea of how they work. Usually the explanations assume a vocabulary that I don't have, so I can't follow them. Where can you learn to work one? Is it so hard that it's next to impossible? I'd like to learn to do engraving--but the salesperson at a jewelry tools store said it was incredibly hard--but I wonder. Does anyone know? Jessica | ||||

|

Jessica, Search Google for "learn engraving", you will find your answer. I don't think is that hard to learn but you must have the requiered tools, basic manual dextrity and the right teacher...and the ambition to learn... | ||||

|

| IHC Life Member Watchmaker |

Jessica, There are many books on the lathe. I would especially recommend "The Watchmaker's Lathe and How to Use It" by Archie Perkins. Bob Tascione has a really good set of vhs tapes that are called "Learn to Turn." They are available for loan through the mail from the library. The Perkin's book may be too new for library availablity. I've seen and bid on (with no luck) an old book called The Jeweler's Engraving Handbook. I'll get one eventually. Hand engraving is a real art. I understand that Patek Phillipe is one of the only watch companies that currently employ hand engravers for custom scene engraving. | |||

|

| Life Achievement Military Expert |

Hello, Jessica. Sorry if I used too much jargon regarding lathes. A video would be a good idea to start. As for engraving, I would suggest a few basic gravers to start with. After you have some gravers, get some thick hard plastic such as the stuff used in place of glass in storm doors. Practice on the plastic. It's easy and fun. Work your way up to aluminum, cooper and other metals. As noted above, a few books on the subject will help. It's not all that hard. If you enjoy it and stick to it you will become good - if you don't like it, you will put the gravers to some other use. Keeping the little gravers sharp is important. There are some tools to help sharpen the gravers which work quite well and make the job of sharpening the little tools faster and more easy to do. Good luck. Best regards, Greg | |||

|

Thanks so much Greg! Getting gravers and the way to proceed sounds just right. The lathe video too. I'm ordering gravers and video tonight or tomorrow, asap. Jessica | ||||

|

| ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide