| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Horological Tools, Books and Miscellaneous

Horological Tools, Books and Miscellaneous  Horological Lathe??

Horological Lathe??

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Horological Tools, Books and Miscellaneous

Horological Tools, Books and Miscellaneous  Horological Lathe??

Horological Lathe??Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

While walking thought the recent Great Lakes Regional with some fellow IHC members, we stopped at a table with an impressive row of jewelers lathes. Everyone admired and expressed what their favorite model was while I began relating (to myself) these tiny beauties to the lathe in my Tool & Die shop. For those who may find it hard to relate size, the red arrow is pointing to my personal jewelers lathe. For those who like specs, here is some of todays new technology. If any member is ever in Cleveland, by all means pay a visit. Weight= 5 tons...Horsepower= 15...RPM=25-2000 variable. Feed rate= 0-600IPM variable....Control= Dual Pentium Windows NT Conversational Control with manual override for servo handlwheel operation. Accuracy and repeatability=.0002in. Cutting Tools= Standard Lathe Tooling and Ceramic/Diamond tip for hardened steels...Communication=Direct Conversation, Off-Line Cad/Cam Computer, Modem for off-site control. I can call this thing up from home...I don't care to do this!! The largest part this lathe can turn is 21"diameterx80"long. Currently I don't have a collet or chuck small enough to hold small stock, but the smoothness and accuracy of the computer servodrive along with the massive rigidity can easily produce the finest watch balance staff. In the past a lathe was run by a person with a sharp eye and a keen set of hands. When this lathe is in full operational mode, the operator watches thru a bullet proof viewing window and touches nothing. He/she no longer has to control motion with hands pulling levers and turning wheels. He/she virtually runs it with their mind thru programing. One great feature the tiny jewelers lathe still has is that you can grab it and run. One thing that will never change...The beloved standard 12" shop clock still hangs on todays machine shop wall. Ralph Rehner, "The Clock Pup" and Longines Watch Guy  | |||

|

| IHC President Life Member |

What a truly amazing piece of equipment Ralph! Thanks for sharing it with us. You mentioned the weight, what is the overall size and what kind of an expenditure is something like that? And by the way, what do you make on it most of the time? Lindell | |||

|

Fantastic piece of equipment Ralph! The jeweler's lathe on top was the perfect touch to give a sense of dimension to the giant! Thanks for sharing that!! Tom Seymour NAWCC #41293 IHC #104 IHC Exec.V.P. | ||||

|

Lindell, The overall size of the machime is referred to as the "Footprint" in out industry. The amount of floorsapce the machine sits on. In this case it is 58-1/2"high x 92-1/2"deep x144"long. An additional 3-4 feet must be allowed behind to access the computers and electronics and facilitate air flow. Thinks can get very warm when heavy current is pulled and hot metal chips are flying. Because it can use ceramic and diamond cutting tools on hardened steel, it's main service is to the automotive metal stamping industry. Large forming steel members for items like the Chryslers Macpherson Strut flanges are created. When their tooling breaks, exact replacement tools must be made quickly in this "Just In Time" economy. Because it can turn an exotic shape quickly from raw stock, and cut the final mirror finished shapes to size after heat treatment (ceramic&diamond tools) the lenghtly form grinding process is eliminated. What used to take weeks now can be done in 2 days. As far as the expendature goes....let's just say when it isn't running parts, or breaks down ....I don't sleep very well, if at all. I relate it to owning and maintaining your own personal elephant...Keep it happy and fed and it will take you anywhere. Starve it or kick it and it will STOMP you into the ground quickly. Remember we have computers involved, and the old "Garbage in Garbage out" rule is in place. Put the wrong stuff in front and this machine can produce volumes of bad stuff out the back quickly. Ralph Rehner, "The Clock Pup" and Longines Watch Guy | ||||

|

Another interesting features that appears to be the computer swung over to the right side is actually only a dual control pendant on a large 8ft' swing boom arm. It has been folded to the right side for this picture and is normally swung way over to the left. The main computer rest behind the machine. The smaller of the two pendants with the cable is a remote detachable control that the operator can wear on a belt or hand hold. It has full control of the machine when activated. Notice the big red buttons......EMERGENCY STOP!!! For those who like to drill holes, the drill in the lathes "Tailstock" is 2" diameter by 12" long and can punch thru solid steel in seconds. I hate sharpening that thing when it gets dull. Ralph Rehner, "The Clock Pup" and Longines Watch Guy | ||||

|

Pretty cool lathe Ralph. Where i work at lee Valley we have mostly Hardinge and Haas cnc machines, we also have 3 big Star lathes with the bar feeders around 20 feet long. I mostly run a automatic Chevalier and a Perfect surface grinder. I almost missed the watch maker,s lathe sitting on top. IHC Member 261 Chapter 111,Ottawa NAWCC Member 158976, Nepean, Canada | ||||

|

Another Toolman!! I just knew there was a toolbrother in this chapter. I have a big Chevalier grinder and it's a workhorse. My CNC mill is a Fadal and my Cad/Cam is MasterCam. On my Americana Fun thread the OG dial I created was through MasterCam. I don't think many of the members understand this kind of powerful software but being a toolman youself it has changed our lives. You know form grinding and can appriciate how much "Hard Turning" has changed that process. This lathe isn't your normal production turning center...just one big nasty metal destroyer for those big tools and dies. I love the new warning signs they put on todays equipment. "Misuse of this machine can seriously injure or KILL the operator. Just the thing you want to read every day when you start work. Ralph Rehner, "The Clock Pup" and Longines Watch Guy | ||||

|

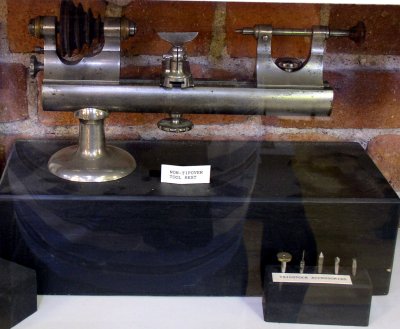

Ralph Thank for posting the photo of "The Lathe", computers and new technology can sure produce some great machinery. Perhaps modern lathe's design began with this type of model.  | ||||

|

Great info,Ralph....I've heard of these,but had not seen one until this.Lathe work will be my next area of new learning.Actually,this could be a specialized area our"Horological Tools....." section.I am fortunate to know a friend who is a master toolcraftsman,but you guys are a somewhat rare breed. Sam Williamson NAWCC 154312 IHC Charter Member 14 Member Chapters 96 and 185 | ||||

|

Nice pic Wayne, If you look closely at my beast you'll still see the concept of the little ancient lathe in your pic. It's just on mine you very rarely touch handles....just buttons and then stand back. For those members that experienced the Great Blackout in America and also the "Blaster" worm virus, just think of the madness that went on with this machine. The new computer driven machines are very sensitive to power cliches and our surge protection safeties were constantly taking the Beast off-line. We finally gave up and pulled the plug for 3 days until power was stable agian. When all this was going on the Blaster Worm virus struck. We didn't even wait. All outside comlinks were disengaged with the outside world. I wouldn't want to think what might have happened if that crazy worm got into the dual Pentium brain of this Lathe and made it go wacky! Ralph Rehner, "The Clock Pup" and Longines Watch Guy | ||||

|

| IHC Member 234 |

...impressive R-squared!!!...Jim C | |||

|

Nice lathe wayne, hopefully this year i will get a watch maker,s lathe. At work we only have one cnc linked to the outer world, it is a Gemmini 5 axis grinder used for mainly grinding drill points like brad points. We now use a proto type Sacron, which is not linked to the outside world.These machines don,t take much to bother them power surges, brown spots , low air pressure can do disastrous things if it forgets where it left off. These are not the problems i would have to face with a small watch maker lathe, hopefully less problems. I wonder what is the heavyiest cut this lathe can do ? IHC Member 261 Chapter 111,Ottawa NAWCC Member 158976, Nepean, Canada | ||||

|

Kevin, On the big lathe 1/4"-1/2" deep cuts in tool steel at high feed rate is easily done. It's the fine micro feeds and depths that are amazing. Ceramic cutting on hardened steel defies the senses. The chip glows red hot yet the finish is fine micro. The tolerences and sizes that can be held are high end accurate. Everything, including the wrenches is BIG. Work with this big stuff all day and then go home to the jewelers lathe. The urge to manhandle things is still with you, and trying to work with the tiny lathe can be frustrating sometimes. Ralph Rehner, "The Clock Pup" and Longines Watch Guy | ||||

|

| IHC Member 155 Bulova Watchmaker |

Thats one big Mama. I have had the pleasure of watching ths machine do it's thing. It can hold some fantastic tolorances. I love the the watchmakers lathe sitting on top of the headstock. Rich Kuhn NAWCC Member 128623 IHC Member 155 Web-Site: http://watchmakerfinds.com eMail: watchmakerfinds@yahoo.com | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide