| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Elgin Safety Table Cracked

Elgin Safety Table Cracked

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Elgin Safety Table Cracked

Elgin Safety Table CrackedGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

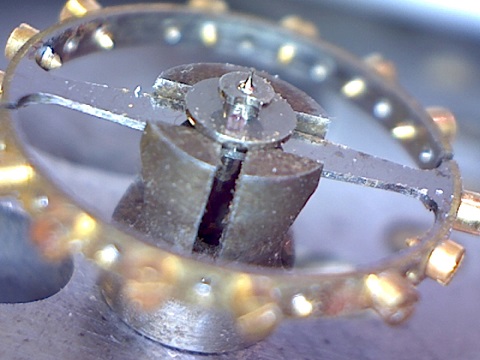

Hi , I am working on an Elgin, where I found that the safety table is cracked and not aligned with the jewel. First I assume that the table is made of two pieces, is that correct? Then what would cause this damage? And where would I go for a replacement? What part #? Do I need to get a complete roller table and safety table? Mel  | |||

|

| IHC Life Member |

This is caused by a replacement staff being of too large a diameter and the repairer hammering the safety roller in place anyway. It can still function normally with a crack but you might want to remove it and turn the staff down for a correct fit. If left untreated, the roller can eventually split in 2. William | |||

|

| IHC Life Member |

Mel, you can probably get a replacement part from Brian Cavanaugh at; pwpartsetc@pwatch.com I suggest you give him the s/n movement plus size and grade# if you have them too. The indexing of the safety roller you show in the picture could be a result of the cracking allowing the roller to be loose on the staff and as Bill White advised, it may eventually break in half completely stopping the watch. | |||

|

Hi William and Dave, Thanks for the input. Is the table a two piece or one piece? (not including the jewel). Can I just replace the safety table, and how important is the alignment? What would be the ramifications of the misalignment of the cutout to the jewel? What a pest with all these questions. Mel | ||||

|

| IHC Life Member |

Melvin, 2 piece. Alignment is important. The guard pin needs to enter and exit this cutout as it passes and would foul other areas of the safety roller if not aligned. William | |||

|

| IHC Life Member |

Mel, the safety roller notch has to be centered on the roller pin to work correctly. These are usually assembled by using the correct stumps and stakes in a good staking set. Trying to manipulate the safety roller as shown in your picture could easily endanger ( BREAK) the Roller jewel so unless the safety roller is falling off, I would disassemble all parts* of the balance wheel and start over again with re-assembly after confirming the new safety roller is a light press fit. (*Hairspring, Roller/Jewel assembly and safety roller) | |||

|

Hi David, This was supposed to be a training project for me. Take it apart, clean, reassemble. I have learned so much. In disassembling, I'm thinking, the safety table will come off easily, since it is cracked. and may split when I take it off. Perhaps I should just rebuild with a new staff, new roller (safety and jeweled), just keep the hairspring assy and the balance. Or should I just look for a complete balance assembly? Mel | ||||

|

| IHC Member 376 Watchmaker |

you should be able to repalce just the safety roller the large roller table should be okay if not cracked,,, on most of these elgin,s the safety roller is the same for both 18 size and 16 size movements. | |||

|

| IHC Life Member |

Mel, Samie said it all. Everything on that balance wheel is fine . . . EXCEPT the Safety Roller. I am sure that Brian Cavanaugh has one of those. Otherwise we could help hook you up with someone who could replace the safety roller and then re-poise the wheel. | |||

|

| IHC Member 1555 |

Should be no need to re-poise the wheel if it was poised to start with due to the safety table being replaced. As the safety roller table is very close to the centre of rotation, but if you are unsure on the initial poise as David said, get it checked. Cheers Bila | |||

|

| IHC Life Member |

Melvin, If you can't find a replacement safety roller, the one with a crack will work just fine if it is allowed to reside on a staff of correct dimensions. You'll need to reduce that portion of the staff for a new roller anyway, right? As you know, the safety roller never comes into contact with the guard pin unless one of the pallet stones is forced from its locked state causing premature impulse. It won't disintegrate just because its cracked and can function normally indefinitely. Just make it fit and you're all set. ....at least that's what I'd do, especially considering that the safety roller is an unseen part with a static function. William | |||

|

Hi and thank you all for your inputs so far. The hairspring came off rather easily, and I hope will go back the same way. I am about to take the roller table and safety table off next. Do they come off together? Assuming they do, do I have the next step set up correctly. A stump with a "T" shaped slot to clear the rear of the roller jewel. See Picture(s) Then the balance assembly (less the Hairspring)  | ||||

|

The assembly  | ||||

|

Then tap lightly after having aligned the stump in the fixture  | ||||

|

Last picture Have not done the deed yet, awaiting comments Mel  | ||||

|

Hi, Thanks for the input. So before I tried to take the roller off, I purchased a replacement. Wouldn't you know it, that safety table was cracked as well. Must be a generic problem with the design.?? To further complicate my dilemma, the punch I was about to use had a broken tip, so I am unable to knock off the original one. Mel | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide