| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  stuck stem retaining screw.

stuck stem retaining screw.

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  stuck stem retaining screw.

stuck stem retaining screw.Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

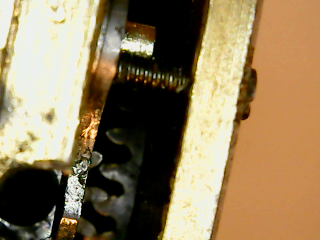

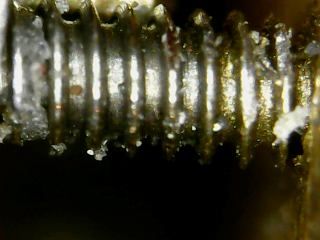

hi everyone, todd here so, tonight i am taking apart an old Cyma, broken MS. this is one of those watches where you have to take out the stem to get the movement out of the case. i have a tremendous amount of experience with this as i did one like it a couple of weeks ago. actually, i am trying to buy a variety of different types of scrapper movements so as to expand my knowledge base. so, on to my problem. the stem retaining screw is totally seized. so much so that i gave up trying to loosen it and backed off the top plate to get enough play to remove the stem. once i got the stem out and the movement out of the case i decided to take a look at the threads of the screw with my microscope to see if maybe it is a LH thread. nope, looks like a RH thread to me. but it doesn't look right. time for a closer look.  | |||

|

so, i zoomed in my microscope and the threads look like someone has grabbed them with a pair of pliers and damaged them. now i know why i can't get this screw out. any suggestions on how to remove it? more importantly is there some sort of tool i can buy to rethread it? i have a tap and die set but the smallest size i have is a little larger than this screw. just a little. i know this watch will never be a collectors item, but that is not why i bought it, i bought it to learn something. perhaps i will learn how to deal with a damaged screw. P.S. the M.S. is not broken, there is no M.S. just the barrel.(very unusual design) todd  | ||||

|

Hi Todd, I am not sure this will work in your instance but for what its worth here it is. I had a similar situation, but not on a watch. Any way, the way I tackled it was to saw a (jeweler's saw) the part that was damaged. And I was lucky the part of the thread that was still in the plate was not damaged. That part of the screw came out easily. This approach may not work for u but maybe it will start you thinking. Easier with the part in hand. | ||||

|

hi Melvin, i thought about cutting off the damaged threads but i cannot move the screw head in the least. i suspect the damage extends up through and into the plate. so i am holding off on cutting while i think about this. i don't want to limit my options by acting rashly. learned a lesson in patience yesterday and took it to heart. i have been contemplating heat to get the screw head moving, then cut so there is less to turn out. but with heat i am worried about warping. but if all else fails there is always explosives! one way or another that screw is coming out!! todd | ||||

|

i haven't been approaching this correctly!!!!! if i had a stuck bolt on an engine i would drill it out! so my question now is, "what is harder? the plate or the screw?" could i punch it out with my staking set? how would i rethread the hole.? i just had an idea! hold on, i'll be right back! ---insert hold music here----- ok, i'm back, sorry about that. look what i found! http://www.ebay.ca/itm/Vintage...&hash=item234d8c51b0 guess what i am going to buy! so all that remains is how do i rethread the hole! todd | ||||

|

Are you bidding on that one? If so, I hope that the punch size that you need to use is not the one that is broken in that set. David | ||||

|

Todd,if you punch out the screw you are going to strip out the thread in the brass plate. It won't just be a matter of retapping the hole. You will have to rethread it a larger size then try to find a larger screw to fit. Punching out a screw is the last thing I would ever do. If you can cut the screw on the underside of the plate the head portion should then unscrew, if not you would have to drill it out keeping the drill size to a fraction under the original. You can then pick out the remainder fairly easily. Looking at it from a pure engineering problem. Mike | ||||

|

| IHC Life Member Certified Watchmaker |

Hi Todd, Bit difficult to see I am assuming that is the set lever/detent screw, from what I see is someone has jammed a screw in to fix it making new threads in upper plate, no doubt the threads in the lower are damaged that once held the correct type of screw for example it would have looked something like in the photo below, a screw section that went in the plate and a shoulder that allowed floating and clamping of detent. first thing to do is stop messing!. Get some penetrating oil and over the couple of days apply a tiny drop on the head and lower thread then carefully try again it may just enough to get it out. If not try separating the plates it may just be clamping down on the detent/lever if not as suggested cut the screw in half, you could then either cut a new slot in the stumps and try and unscrew it. those punches on ebay you have already just modify and use some old screwdriver blades.  | |||

|

| IHC Life Member |

Todd, if you do end up cutting the screw and need to get the remainder out of the stem retainer, you may want to try the alum trick, I stumbled over this solution, check these posts. Some advice on removing this broken screw, please. "Find-Or-Search" for alum in IHC Watch Repair Forum | |||

|

hi Bruce, that is fantastic! i didn't even consider a chemistry solution to this problem. right now i have the plate soaking in penetrating oil, if that doesn't work i will have to find some Alum. thanks a lot! todd | ||||

|

A good grocery store will have Alum in the spice section. Dave Turner | ||||

|

| IHC Life Member Certified Watchmaker |

Alum works well on most screws, patience is the key 3-5 days and a daily poke and scrape with a needle helps, There is a quicker solution but a much more hazardous procedure in every respect, Vissin for Removing Broken Screws. Vissin Screw Extracting Solution Instructions: Immerse in a crucible and heat to a simmer under a low flame until a black substance exudes from the screw hole. Rinse with running water and clean in benzene. Replaces all mechanical methods of screw removal. Caution: Causes severe burns | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide