| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  ROLLER JEWELS. SOLVED

ROLLER JEWELS. SOLVED

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  ROLLER JEWELS. SOLVED

ROLLER JEWELS. SOLVEDGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

Why or who says roller jewels have to be of jewel material? Why not a metal rod soldered to the table? You could file it to fit. | ||

|

| IHC Life Member |

Patrick, Roller jewels are an intended to minimize sliding friction between the roller jewel and the pallet fork. A polished hard stone such as synthetic ruby will slide quite easily against hard steel, brass against steel will work, but it's important to remember that a detached lever escapement relies on brief and minimal friction for optimal performance. If you were to replace the roller jewel with a brass or steel pin, said performance would be compromised. William | |||

|

| IHC Life Member |

Sounds good to me. I figured there was a good reason but I didn't consider friction. | |||

|

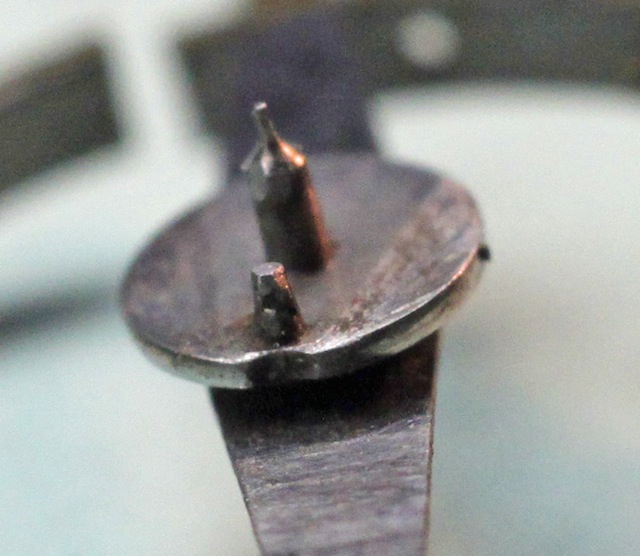

I found a balance wheel in my junk parts drawer that had a steel roller 'jewel' installed by someone. You can see from the photo that the end has some significant wear. I'm sure the performance would definitely have been compromised.  | ||||

|

Robert, I have seen the same thing but with a piece of brass rod in place of the jewel pin. Why would someone go through all the trouble of making a brass "pin" to fit the watch when it would have been less work to just replace the jewel ?? Kindest regards, Serge | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide