| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Help needed

Help needed

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Help needed

Help neededPage 1 2

Related Content: Pocket Watch Discussions

Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Good morning to all, i am in need of 15 to 20 screws particularly heavy for balance wheel . Head should be 1,5 millimetres around and heigh 1,5 millimetres, the screwed part should be 0,40 millimetres to 0,50, lenght 1,5 millimetres .....anyone can help? mtks rgds Enzo | |||

|

| IHC Life Member |

Enzo please help us by explaining what watch movement this balance wheel is used on. | |||

|

Hello David, thank you for yr answer and support! I hope you would not mind if I ask a theory' question. I have never checked the material nature of the balance screws....normally they seemed to me like being brass but I presume that sometimes in some particular watches they had been made in gold. Being that tiny nobody thinks to check their nature, if they are gold or what....you would know that nature by your own knowledge about that particular watch. Gold has a specific weight which is more than the double of the brass and if screws of a given balance wheel are made in gold there is no way to vibrate an hairpring if you substitute them with brass ones...the balance wheel will never oscillate to the proper frequency and will be FASTER .... Infact the momentum of the gold screws' balance wheel is more than the double of the one of the same diametre equipped with brass screws. That is just my own speculation as I do not know if this is correct and if that is commonly found on watches....better, i do not know and i would like to know which of the American and English watches has ever used gold screws. The above to investigate on a subject which has not been frequently addressed. Comments about that are most welcome. Tnks rgds Enzo | ||||

|

Very interesting, I'll be watching for this answer too! Sheila | ||||

|

| IHC Life Member |

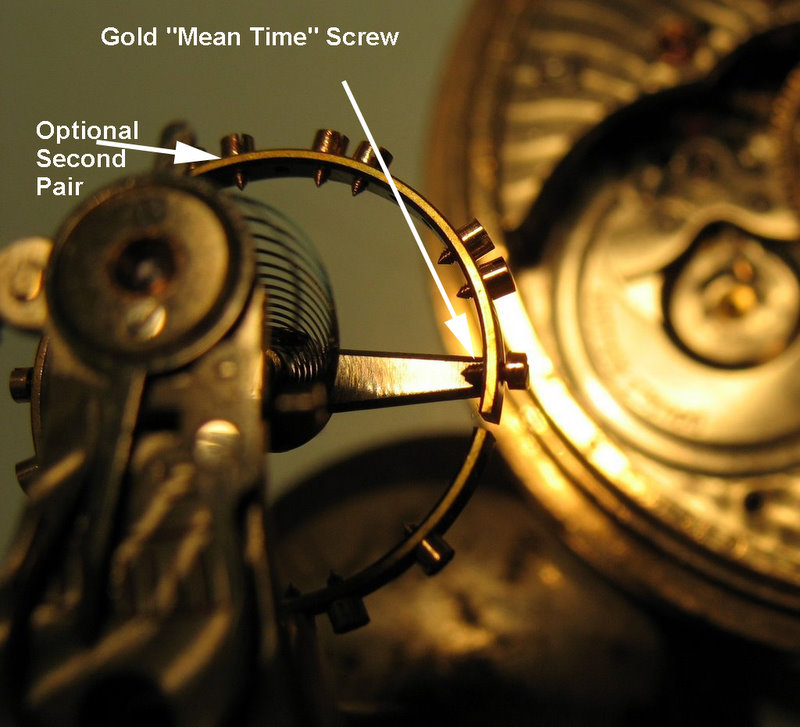

Enzo and Sheila, Luckily, I had a 19 Jewel Bunn on the bench that I could use to help convey MY understanding (on US-Made watches) of the Timing screw situation. First,"Mean Time" (MT) screws were fitted to the Balance wheels for MOST (except Elgin who rarely used ANY) US-made Pocket watches that were marked "Adjusted" (3 or more "position" adjustments) Second, Gold (because higher mass Gold imparted a faster change in the Inertial reaction diameter of the balance wheel) was the material of choice for MOST MT screws. The purpose of MT screws is to "fine tune" the speed of the watch, reducing timing error to the point where the watches can then be properly readjusted to positions. Third, MT screws can be recognized as they are not usually "bottomed out" to the Balance wheel rim, and they are Jam threads so they should only be adjusted with a mean time screw holder.(NEVER USE A SCREWDRIVER ON ANY TIMING SCREWS!) Fourth, The basic "Adjusted" watches had at least 1 Pair of these Mean Time Screws, and some higher level watches had 2 pairs. (Note, in the photo I show "optional second pair" for position reference only, the screws on that wheel are actually NOT MT screws.dca) Fifth, All of the other timing screws on the balance wheel are usually hard brass, and were used to bring the wheel to speed and poise. Then later to readjust it for temperature. The distinction that can be easily made for a higher end watch (RR grade, etc., etc.) are if there is at least 1 pair of Mean Time screws on the Balance wheel, and the escape wheel is steel. I make this point because many, many very high grade 19th century watches have steel escape wheels and up to 4 MT screws while using "only" 15 (very expensive at the time) jewels!  | |||

|

| IHC Member 1101 Site Moderator |

Very interesting information David. I was wondering if you could ellaborate on how the watchmakers a hundred years ago would do the timing on these watches. Did they have a big clock on the wall they compared with? Obviously they did not have the electronic calibration equipment we have around today and with that being said, how long would would it take them on average to correctly time a watch? Steve | |||

|

| IHC Member 179 E. Howard Expert |

As far as i know all the early Howards came with solid gold balance screws and even my "Hound" grade watches, which were not adjusted to temperature or position, have two sets or four meantime screws as this picture shows. The highest number of balance screws I have seen on an early Howard is 26, this is on a small Gsz (6size).  | |||

|

Many thanks to all for answers and for the new questions.... David, very interesting indeed, i will have to do some trials on my balance wheel to apply that theory.... if I did not misunderstand all above applies mainly to bimetallic balance wheels, they are the only capable to be adjusted to 6 pos and that is where i am interested in at moment......now the question is : how much the gold MT screws impact on the momentum of the balance wheel, in other words, how much will anticipate a watch if you substitute the gold MT screws with brass ones of exactly same dimensions ( naturally the mass will be much different) ? Unfortunately I do not have these gold screws for my balance wheel yet and that is the reason why I made this post. I will need to rely on yr kind support if you do not mind.... The fact that the gold MT screws are used for ''fine tuning'' surely means that they ''work'' over small portions of an arc and in accordance to the different type of position's adjustings. Therefore I should assume that by these micro changes the momentum of the balance wheel is altered infinitesimally but still capable of advancing/retarding by single seconds the watch in the different positions in the search of the mean setting. If so the substitution of gold screws with brass screws would dramatically change the timing of the watch anticipating the watch probably by an hour or so per day. I have not found a formula to calculate all the above and I doubt any exists so we need probably to rely on the experience. I look forward to hear from you about... tnks rgds Enzo | ||||

|

Hello, this is just to ack the Harold's post, tnks enzo | ||||

|

| IHC Life Member |

Interesting reaction to my little dissertation, which is (of course) an opinion only. Firstly, Steve, not long after Gallileo, the time was pretty well ascertained using astronomical observations, and as long as you knew your Longitude and Latitude you could pretty well determine the time to a second or better. That is why all the leading US watch companies had their own astronomical observatories. Secondly, the balance wheels were usually suspended from their balance springs and rotationally "vibrated" (resonated) comparativly to check their excitation frequency which should be their accurate beat period. Then the weights were added or taken away to achieve the correct frequency of excitation. Harold, you will note I said "usually" when referring to materials for timing screws. We all know the excesses that were squandered on some of the higher end watches, including the ruby "bumper" jewels on the Keystone/Howards. I have a 12s Howard that I really love for its built-in stopworks, that at least had an excuse for being used. Enzo, By using MT screws to slightly adjust the moments of inertia of the wheel, you are not affecting the mass of the wheel but rather its speed of oscillation. Changing from brass to gold balance screws will of course do the same thing by increasing the mass to such an extent that the moment of inertia is greatly modified too. Given this, you would have to also stiffen the balance spring to keep the frequency up to correct rates. One other observation I have made, those watches which were expected to keep very good time also have heavier Balance springs (Hair springs) and many more balance screws on them which will certainly encourage a more consistent periodicity of oscillation. The accuracy is (of course) a completely different thing. | |||

|

Again many thanks for the explanation David, i agree with your observations and meanwhile I kept researching and found that on a modern balance wheel the positions all-in all-out of the screws are giving the watch an advance/retard of 150 sec per day...which i would assume more or less the same for a conventional balance wheel. As rule of thumb, being the radius the same, if a couple of brass screw is replaced with a gold ones ( double mass weight) it will double the 150 sec/day to 300 sec/day or more.... That explains why I am not able tune a balance wheel assy (bal wheel complete and relevant hairspring) to correct beat unless I will install some gold screws where momentarely I put brass screws.... I am fabricating these gold screws to replace the brass ones and I will be pleased to share the results of my findings. Meanwhile I post a link which I found interesting to me and probably to you because of the reference to Hamilton experiences... http://www.bhi.co.uk/hj/AOM%20August%2007.pdf rgds | ||||

|

| IHC Life Member |

By the way, I used an American slang term for what the british call "Interference" threads. i.e. the MT screws are threaded with dies that leave a slightly "fatter" thread "v" angle profile (not diameter) that results in a light intereference fit when the MT balance screws are threaded into their tapped holes on the periphery of the Balance wheel. When the MT screws are adjusted for timing (and sometimes to aid in the poising of the wheel.) they can be left in what appears to be a "loose" position because the interference threads prevent them from changing setting. | |||

|

Hi everybody, so I fabricated the 6 gold screws I needeed and it wasnt a joke as the thread is 0,35 millimetre in diametre but anyway i substituted with them 6 brass screws out of the total 16 on my balance wheel and the change in timing of the watch had a dramatic change... Before that I could not make the balance wheel to have the correct alternances and the its swinging was far to be the correct one and way too fast... That 6 gold screws really slowed the balance speed to the correct alternance ratio just found by trials. thnks for help and rgds | ||||

|

Hi, This is how teorically the weight (P) of the screws impacts on the momentum of inertia (I) of the balance wheel of given diametre (D) under influence of gravity value (g). ... P D^2 I= -------- ... 4 g As it is seen the difference is mass/weight of brass and gold screws changes meaningfully the resultant value of the momentum. rgds | ||||

|

| IHC Life Member |

Magnificent simplification. As you know the balance ("hair") springs are the equivalent of Gravity, so that to obtain the effect of greater or lesser mass a Horologist may manipulate EITHER the Balance weights (P), or the stiffness of the Balance springs (G). In your case, you chose to use the same Balance spring (G) and manipulate the mass. | |||

|

| Site Administrator IHC Life Member |

Did What?????????????? I am still learning how to wind the things. | |||

|

Hi Evrbdy, it is time to give some explanations before this thread becomes too cryptic and not of much help to the many.... I bought a Lange & Sohne watch cal 48.1 (the ones that were used by Luftwaffe pilots) but it had no balance wheel assy. From another source I got the balance wheel, the hairspring and the plataux. But the balance wheel had no screws installed, they were completely missing...and actually they are no few... After having assembled the balance wheel with the hairspring and the plataux (the disk) and put in the watch, naturally I runned way too fast and i considered to install a convenient number of balance screws. That was the time when I started the thread to look for the screws...infact the screws were quite peculiar having that thin diametre thread (0,35 millimetres)and with the help of a pic of another similar watch I also managed to guess the head diametre. Finally I found that type of brass screws at a friend' but after reworking the thread and installed the watch was still too fast. Then I realized that the original screws would have been made of gold because that was the only way to slow the high ''speed'' of the balance wheel. You now know the story and the relevant conclusions. rgds Enzo | ||||

|

OK, so that leaves me with just one question. Why didn't Elgin's need them? What did they do differently? Sheila | ||||

|

| IHC Life Member |

Sheila, Elgin used Balance screws, the issue with them is they seemed to avoid the extra cost of installing the heavier gold mean time screws. Evidently they had a "superior" means of watch timing at the factory that avoided the need to "tweak" the timing with Mean time screws. | |||

|

Hi there, i became now curious how Elgin did factory timing trimming..David, can you say more and pls post a generic pics of an Elgin balance wheel? Generally speaking the usage of gold screws is not necessarely required when designing a balance wheel but if originally they were installed then they should be there. It is correct the asumption of working on the hairspring to correct mass/weight problems that impact on the behaviour of the balance wheel but it is impossible to correct the hairspring when the weights are less than what was required. You should agree that in my case I had no other way than to work on the balance weigths. Incidentally I would like to mention a watchmaker' trick which I suggested not to be regularly used but could be the last resource with severe Hairspring problems. When an hairspring is too ''stiff'' for the balance wheel such that it runs really toooo fast a light (3%) solution of nitric acid dip for a few seconds will soften it if blued steel. It requires a wash in benzine before and in ammonia after and the benzine again. Testing after re-installation by the vibrating fixture will confirm proper frequency and if not then additional dips until frequency reached. Unfortunately that doesnt work on Elinvar hairsprings. tnks rgds Enzo | ||||

|

| IHC Member 1101 Site Moderator |

Enzo, Have you got enough thread on the screws to get washers, maybe lead, to increase the mass around the ouside of the balance wheel thus increasing your inertia? Just a thought. Steve | |||

|

| IHC Life Member |

Good thing I understand the theory and relationship between the stronger (thicker) hairspring and the balance screws cause I sure as heck don't have a clue what you guys are talking about with the mathematical formulas. I guess I should have been more attentive in math classes. Come to think of it, how did I ever get thru college? | |||

|

Hi Steve, probably yes but the specific weight of lead is just a little more (20%) of the brass. Gold instead is over 130% of the brass. ....You would need a too thick washers.... But the main reason to prefer gold screws instead was due to aestetic reasons...a mix of lead and brass on a L&S would have looked not a too proper fix... rgds | ||||

|

Do not worry Roger, i had to go to books again now to explain myself the many horological riddles, it is always time for... rgds | ||||

|

| IHC Life Member |

Enzo, I suffer the humility of ignorance once again. To show you a "no MT screw" Elgin, I opened up a nearby 18s Elgin Model 8, 17 Jewel RR grade, and found that ( 1. It looks like ALL the balance screws are GOLD! ! ! !, and; 2. . . . IT HAS BALANCE NUTS! The picture shows the movement on left and on the right, it shows 1 (of the 4 on this watch) gold NUTS that can be adjusted by turning it in out out on the threads of the steel stud fitted to the balance wheel. The picture is out of focus but you can see the dark center of the balance nut which is a hole to accept the steel stud. This system is superior in many ways to the other MT screws because it will not break easily, and it is easier to manipulate the nut. So I was WRONG, Elgins DO use MT screw/nuts and they are BETTER for the purpose!  | |||

|

Hi David, very interesting indeed, many thanks for showing that, I understand well the system they used at Elgin, very peculiar !!! and pls do not say that, because we are all ignorant against the too wide science of horology and outmost skill of our horological precedessors It has been a very interesting thread dealing with an argument that is not often considered... It was the capability of some L&S watches to keep 0,5 sec per day that convinced me to try to get same results..i will keep you posted on the outcome of my repair... many tnks again for yr support. Enzo | ||||

|

| IHC Life Member |

Now you guys shamed me into digging into a 3/0 Elgin that I put a new hairspring in a couple of weeks ago. After I did that it ran 2 seconds slow every minute and I knew I'd have to tackle the balance. I got lucky. Took out 2 screws and it is right on now. Brings up another possible issue. How does adding/removing screws impact poising? | |||

|

Sure it impacts poising Roger, if it had any before that, but you can win them all if you reinstall the screws where you took them from and you do static poising by undercutting the screws. keep also yr eyes open rgds | ||||

|

| IHC Life Member |

In the case of the 3/0 Elgin, I was doing a complete cleaning and oiling. After cleaning everything I only replaced the hairspring. When I took the old hairspring off the balance wheel I checked poise and it was perfect. I put the new hairspring in and put the balance assembly on the balance cock and installed it in the watch by itself to get it in beat (roller jewel between banking pins) and make sure it had good movement and wasn't binding on anything. After all was completed and assembled I had the 2 second per minute slow problem. After removing 2 balance screws it is now keeping good time. It is a 7 jewel movement so I don't expect miracles, but it is keeping good time dial up and dial down so far. I will check it in other positions, but unless it is really bad it will be left as is. BTW, my apologies if I have hijacked your original thread. | |||

|

No problem at all Roger, the more we discuss the balance behaviour the better it is...understand your process and i see less or little impact for a non-properly poised balance in dial-up dial-down regulations, you should experience some problems in pendent-up pendent-down position etc where the gravity force has major impact on an unbalanced balance wheel and also in temperature reg if you have a cut balance (i do not know the balance assy of that watch) as the changes in shape of bimetallic balance wheel counteracts the behaviour of the hairspring but in where the mass of the screws has also some influence. All the above is theoretical and could be un-noticeable in an ancient watch due to different reasons but it is true on a newly manufactured watch. I look forward to hear from you after you complete the trials. rgds Enzo | ||||

|

| Powered by Social Strata | Page 1 2 |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide