| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Pocahontas fixed, now cursing the Iroquois

Pocahontas fixed, now cursing the Iroquois

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Pocahontas fixed, now cursing the Iroquois

Pocahontas fixed, now cursing the IroquoisGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Member 1736 |

What an incredible learning curve. I'm still really new to this whole COA thing... I've dabbled with a few here and there, but mostly took stuff to Dave. Now that the remodel of my study is done and I have room to spread out and do this at home... I got in to a mode where I was trying to get two a week done... A bit fool hardy at this rate. I'd like to think I've seen most of the curve balls these watches will throw at me... but... Now; this Pocahontas was a runner going in to the project and I hated to tear her down, but she is headed out the door and I wanted to be able to say she was 100%. While it was apart, I noticed the escape wheel had odd wear... I had a good spare with a bad staff... so, I got to do my first wheel swap. So, being all proud of myself for about a whole two minutes... then she stopped... just stopped... at random intervals... 2 minutes, 20 minutes... what ever... it acted like it was "over banking" but would start back up if I looked cross eyed at the escape wheel... So, being convinced I did something wrong when I swapped the wheels... I tore the whole watch back down.. even the cap jewels... trying to figure out what was amiss. This time it went back together and the escape would not advance at all... The pallet fork would toggle, but the escape wheel would not advance... all free spins checked out good. The third time I repeated all jewel and assembly checks... I finally noticed daylight behind the pallet jewels. I reckon it ain't supposed to be there.  | ||

|

Space behind the pallet jewel to the back of the slot that holds the jewel allows for adjusting the jewel forward or back in the slot to adjust the escapement action. The presence of space isn't a problem -- the amount might need to be changed if the engagement of the jewel with the escapement isn't correct. | ||||

|

| IHC Member 1555 |

Before adjusting the pallet jewels I would be rechecking the two escape wheels to make sure that they are the same. I have come across this before where someone swapped out parts from a similar movement but serial numbers apart and there has been a difference. Just my two bobs worth. Regards, Bila | |||

|

| IHC Life Member |

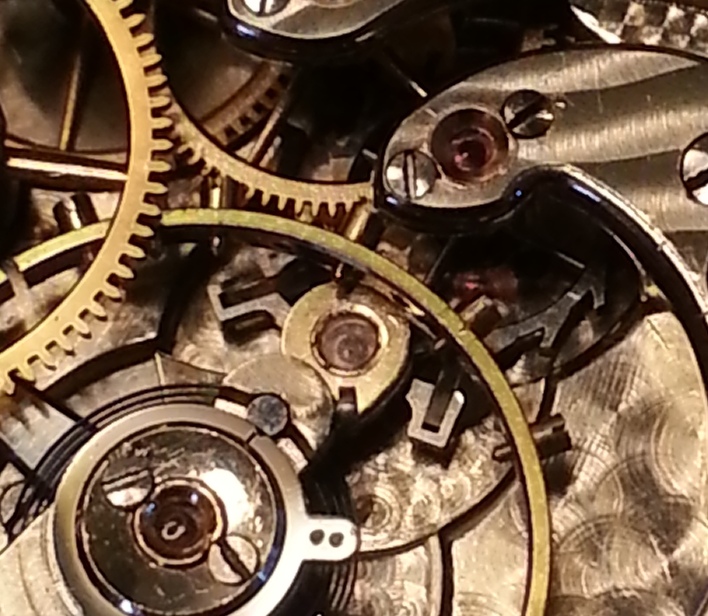

Maybe it's just the picture, but it sure looks like there is a missing tooth on what appears to be the fourth wheel. Also looks like some tooth damage to the right of where the missing tooth is. | |||

|

| IHC Member 1736 |

What a difference a gazzilianth of an inch makes. I had the luxury of having the Chevy and Cadillac models side by side. I studied the lock and unlock of the Iroquois and compared to the Pocahontas. The left jewel of the Pocahontas was just barely not clearing the tip of the toe that trails the arm on the escape wheel. I pulled the pallet fork and scrutinized it thoroughly. The jewels were perfectly parallel and solid in the hands of the scorpion. No reason to suspect they had drifted forward out of their seats. The fourth wheel and escape wheel suffered similar scrutiny. The appearance of an issue with the teeth on the fourth wheel had to do with the camera angle (eg. shadow) and masking by the balance wheel weight.. I rotated the outboard banking pin less than 5 degrees open as indexed by the screw driver slot... put the pallet fork back in and got great results. The pallet snaps left and right with the lightest flick of the scorpions tail. engagement to the escape wheel is on the short side of 1/3, but is essentially identical to the Iroquois... Installed the balance and off she went... just like she never had an issue. Thank you to everyone for the million mile apprenticeship. Your various inputs and Dave's phone call put all my fears aside and helped me focus on the check downs to get her back.  | |||

|

Good job Paul, Sounds like you're getting on top of it. Dave Turner | ||||

|

| IHC Member 716 |

Hello Paul Nice Rockford. that's a hard one to find. Doug | |||

|

| IHC Member 1736 |

The Poco is happy, keeping RR time, smooth. It's little sister the Iroquois is killing me. I finally gave up trying to figure out the whole roller pivot thing and am going to replace the staff this weekend. If that don't fix it.. I'll end up sending it to someone. It's another one with something I don't understand going on between the balance/pallet fork/escape... I had to step away from the flame for a couple days and work on some other projects to clear my mind and take a fresh look at it sometime later. When I complete the pair, I intend to market them side by side. They look like twins, production runs six months apart. Factory cases, similar dials, the Poco is DS the Iroquois is SS. The Poco comes up as 1 of 100... I'm sure there must have been more than 100 made... perhaps this is just the variant? | |||

|

| IHC Member 716 |

Sure feels good when you get a watch together and it takes off running. have you tried just putting the balance on the watch without the pallet folk or gear train in.? " you can get a better look at it if the gear train is not installed". get the balance moving with a little air or just a twist of the movement. if it only osculates a few times. take a good look at the pivots, look for dried oil in the jewels, cracked jewels, the hair spring rubbing on something. try moving the balance up and down to see if you have clearance between the pivot and cap jewel. if I'm not sure where the problem is. I like to start with the balance to see if its in good working order first. best of luck with the Iroquois. from what I can tell. the total production on the Pocahontas is 100. | |||

|

| IHC Life Member |

I think Roger is on to something. The watch in the photo is MISSING at least 1 tooth and about 3 bent teeth. Let me guess a broken mainspring also. With this many messed up teeth it WOULD STOP radically at different times. GOOD EYE RODGER. I would also venture to say that when the mainspring broke. It put so much stress on the third wheel it ripped a few teeth. and maybe bent the arm of the pallet fork trying to hold all of that force. and that is why you had to adjust the banking pin.  | |||

|

| IHC Life Member |

Not quite that good Eugene. Paul explains above that shadows from the balance screws makes the teeth appear missing/damaged. | |||

|

| IHC Life Member |

I was wrong again. I'm happy you got it running. | |||

|

| IHC Member 1736 |

Thanks to all, The topic has morphed from the Poco to the Iroquois... The Poco is running like a champ, the Iroquois was giving me fits. I got it figured out, just need to figure out how to fix it. The watch had a cracked pivot jewel. I replaced the jewel with a jewel from a donar watch. The balance minus the pallet and hair spring spins free... until it gets slow then all of a sudden I can detect that it drags and stops... Turns out the timing screw is just barely contacting the 4th wheel. This watch has such close tolerances with the balance wheel coming in under the center wheel and above the 4th wheel with only a few ten thousandths of an inch clearance. I think it was Roger that said, "watch it until it comes to a complete and smooth stop" "in every position"... I did not do that initially... It spins at high speed with no indication of a drag issue... it is only when it is a couple spins from stopping that it is obvious that it is hanging up. The pivot looks good, but the new one in my stash measures at .180" long and the one on in the watch measures at .178" long. It only does it face down, which makes sense because the balance is at it's fullest depth in the pillar jewel in that position... and it appears to be only one of the four timing screws... but the balance checks out to be true... so it could be drilled just that one ten thousandths lower than the rest. Understanding the problem is the first step... now, I just need to figure out how to restore the clearance. I'm pretty sure I have plenty of end play to work with... will know soon. | |||

|

| IHC Life Member |

A couple of things come to mind. Since the same part number staff can have several pivot sizes, the hole jewel must be sized to that pivot. A test fit of the hole jewel over the pivot should always be made before installation. Next, I have seen many cases where the cap jewel is not fully seated and the pivot either travels too far with excessive end shake of the staff before contacting the cap jewel or the coned area of the staff starts riding on the hole jewel instead of the end of the pivot contacting the cap jewel. Sometimes it can be very subtle with the coned area barely touching the hole jewel. With persistence you will find the problem whether it be something suggested here on the forum or on your own. Let us know what it ultimately turns out to be. | |||

|

| IHC Member 1736 |

Putting a new staff in the watch fixed all my clearance issues. I can't believe how long I fought the idea of restaffing the watch thinking the pivots were fine... I probably could have saved two afternoons of fiddle farting around with this watch if I had just bit the bullet and restaffed it up front. | |||

|

| IHC Member 1335 |

| |||

|

| IHC Life Member |

Paul, I love this kind of posting. Not only is it educational but proves that we some times ignore the obvious. We all do it and when it is brought to our attention we learn from it. Paul, don't let it give you fits. Just take an extra hour and read your books until you understand. Then give it a try. It's kind of like "If all else fails read the instructions". | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Pocahontas fixed, now cursing the Iroquois

Pocahontas fixed, now cursing the Iroquois

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Pocahontas fixed, now cursing the Iroquois

Pocahontas fixed, now cursing the Iroquois©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide