| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Safety Barrels and Motor Barrels?

Safety Barrels and Motor Barrels?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Safety Barrels and Motor Barrels?

Safety Barrels and Motor Barrels?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Posting to the Hampton #104 thread Ed Ueberall said: >> Any watch marked "safety pinion" will contain a going barrel, it was not needed on a motor barrel ... It was not that I doubted the veracity of Ed's statement, but it triggered my thinking about safety barrels and motor barrels. Elgin appears to have used the terms interchangeably. Those Elgin watches which I have seen marked "Safety Barrel" are listed in their database as having a motor barrel. Are safety barrels and motor barrels the same? I had always thought that they were the same, but now nagging curiosity needs to be satisfied. Thanks for any untangling that you can offer. - Mark Lee | |||

|

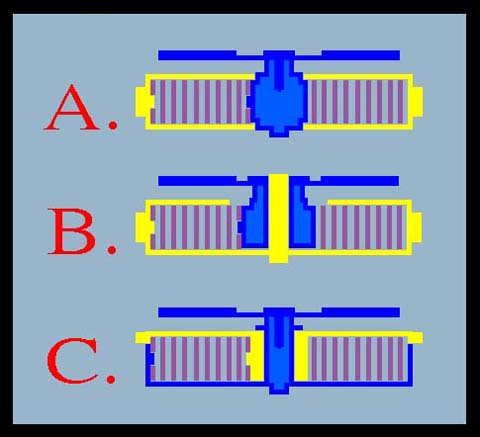

Hi Mark, Here is the response and sketch I received from Steve Maddox sometime ago when I asked a similar question of him. Rob ______________________________________________ In order to really understand the problem that arises when a mainspring breaks, it's better to think of the spring as a long coil spring (like a screen door spring), rather than the spiral spring that's actually used. With any type of spring, the force at one end is equal to the force at the other end. In other words, if you stretched out a screen door spring between your two hands, each hand would be pulling an exactly equal amount of force. That means that regardless of which end of the spring is 'fixed,' and which is 'movable,' each end has exactly the same force. Now, with the door spring stretched between your hands, imagine what would happen if it were to suddenly break (particularly somewhere near one end). All the tension would be released immediately, and the two resulting sections of the spring would generate considerable momentum as they snapped back into their 'natural' (relaxed) state. Obviously, the largest portion would develop the most momentum, and as soon as the 'slack' was absorbed, the spring would act like a hammer. When a watch mainspring breaks, exactly the same thing happens. Of course, it's possible for a spring to break at any point, but the most common failure sites are near the ends. In a watch with a standard 'going barrel,' if the spring breaks near the barrel hook (outer end), it's not likely that any harm will result to the movement. Several coils of the spring will rapidly unwind inside the barrel, but the attached end remains anchored to the barrel arbor, and once the spring starts to unwind, the loose (outer) end will begin expanding in the barrel and acting like a 'brake' to slow the rate of release by relatively gradual degrees. On the other hand, when the mainspring breaks near barrel arbor (inner end), the entire length of the spring is free to develop a huge amount of momentum as it rapidly unwinds to fill the barrel. Since the only thing that's holding the barrel is the engagement of its teeth with the center wheel, at the instant when the spring reaches the end of it's available expansion room, all the momentum it's developed is going to be transferred to the barrel teeth, center pinion, etc., and it's very likely that it will be more than some of those parts can take. In watches equipped with a 'safety barrel,' the outside of the barrel is actually attached to the barrel arbor (via a square or 'D-shaped' hole in the barrel and a matching shoulder on the arbor). When a mainspring breaks and the broken end develops momentum as it unwinds, the force once it reaches the end is transmitted through the barrel arbor, and the ratchet wheel is free to rotate until the force is harmlessly expended. The 'arbor hook' is ultimately attached to the 'great wheel,' which is what drives the center wheel. The 'barrel hook' is ultimately attached to the ratchet wheel, instead of the center wheel, as it would be in a conventional 'going barrel.' With the 'motor barrel' such as employed in Hamilton and Illinois products (as well as a few others), the outer end of the mainspring is attached to the outside of the barrel, which has the wheel teeth on it, exactly like an ordinary 'going barrel.' With this set up, the advantage gained by the 'safety barrel' system is lost, and a broken mainspring would still result in the same shock to the gearing as in a watch equipped with a 'going barrel.' In conclusion, a 'motor barrel' isn't equivalent to a 'safety barrel,' and the terms really shouldn't be used interchangeably. With 'safety barrels,' such as are commonly found in many Waltham and Elgin models, a safety pinion on the center wheel isn't necessary. Watches equipped with only a 'motor barrel,' however, have no more 'safety' factor than a watch with an ordinary 'going barrel,' and they still require the use of a 'safety pinion.' In the accompanying sketch, figure "A" depicts a cutaway view of a standard "going barrel." Figure "B" depicts a similar view of a "motor barrel" (such as was used by Hamilton, Illinois, etc.), and figure "C" a view of a "safety barrel," as was used by Waltham (Elgin used a different, but similar arrangement). In all of the figures, winding is accomplished by the blue parts (the ratchet wheel is at the top of each figure), and power to the train is applied through the yellow parts (the "great wheel"). A cutaway view of the mainspring is represented by the purple bars. Note that in figures "A" and "B," power is supplied to the train by the outer end of the mainspring, and winding is accomplished through the inner end). In figure "C," however, power is supplied to the train by the INNER end of the mainspring, and winding is accomplished by the outer. This makes all the difference in whether or not a safety pinion is needed in the event of mainspring failure.  | ||||

|

Rob; Thanks for passing the information along. It appears as though what was old was made new again by the use of a new name. - Mark Lee | ||||

|

| IHC Life Member RR Watch Expert |

Mark, A Safety Pinion is part of the center wheel and is needed to protect the gear train using a going barrel. A safety barrel and a motor barrel are similar in construction and do not require a safety pinion to protect the train. I may not have expressed my earlier post very clearly. Sorry about any confusion. Ed Ueberall IHC Member 34 The Escapement | |||

|

Ed; Thanks for the clarification, but importance of your statement was to revive my confusion about safety barrels, not pinions. The term "safety" just happened to be both names, but it was just enough to get me thinking again. - Mark Lee | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide