| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Is anyone repairing feet on a Dial

Is anyone repairing feet on a Dial

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Is anyone repairing feet on a Dial

Is anyone repairing feet on a DialGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

I found a quick way to repair the feet. I purchased some brass flat headed brads the correct diameter and used a commercial grade glue I purchased from a vendor in South Dakota. I glued the head to the proper location on the dial. When the glue dried I cut the brads off at the correct height. The dial fits and works properly. After confering with Larry Fure who tried to solder new feet and ruined the dials I decided that my commercial glue would do the job. So far they have held up great. After I fixed the dials Larry pointed me to a vendor on Ebay who sells replacement feet. These are more expensive but may actually work better. | |||

|

| IHC Life Member Site Moderator |

Ernie If you ever want to try again, I bought some of those feet a few years back but have never used them, I would be happy to give you a few. Tom | |||

|

Hi Tom: I would like to try the commercial made feet once but right now I don't have any dials that need feet. I have been temped to purchase some but have had other priorities. I will email you with my address if you would like to share a few. If you have any dials that need feet I will be happy to glue them on for you at no cost. It would be nice to get some dials out there to test the glue method and bonding ability. Ernie | ||||

|

| IHC Life Member Site Moderator |

Got your email Ernie, I will get them off to you, I will see if I have any dials you can practice on. If I don't have any that need it, I do have a lot of real bad dials that I just can't toss, you could cut the feet off & try putting them back if you are interested. Tom | |||

|

| IHC Life Member South-Bend |

Ernie, what type of glue are you using? I've tried a few in the past and never had satisfying results myself. Perhaps your choice of glue and feet are a serendipitous combination? | |||

|

| Watchmaker |

Hi Ernie, I have used my Laser Welder to repair dial feet before with a good outcome. It does get alittle tricky with a very rare or expensive dial. The first picture shows a damaged Elgin dial with a broke dial foot. The outer pictures shows the welds. Take a look and tell me what you think. Leon  | |||

|

| Watchmaker |

This picture shows the back of the dial and weld.  | |||

|

| Watchmaker |

Close up of the laser weld this is done while I hold the dial in my hands so I can feel if the dial even starts to get warm. On most dials you can use a wet paper towel to keep the heet down and not mess up the dial.  | |||

|

Leon: Your Laser repair looks good. It is perhaps more permanant than my glued repair. However there is no heet in my repair and does not damage the dial. Time will tell if it holds up. Frank: The name of the glue is EZZY FIX Industrial Adhesive from Groton Enterprise, Groton, SD. It is guarenteed to stick wood, steel, porcelain, PMMA, rubber, hard PVC, leather, ABS. So far it has worked well but I have only tried it on two dials. I made a jig for my South Bend dial to find the exact location and tried gluing the old broken off feet back on. It didn't work at all as I didn't have enough surface space for the glue on the old posts. Then I hit on the idea of using new feet from the correct diameter flat headed brass brads. So far it has held up great. But it has only been since shortly after Christmas. More time will tell. I have had great success using this glue on other projects in my business. The reason I bought it the first time was the immediate result I saw in the demonstration. The demonstrator took a bungee cord, cut it in two. Then he applied a couple of drops of the glue to the cut off end, stuck them together and pulled them apart briefly. Then he stick the ends together and gave me one end to pull on. He pulled on the other end. We could not pull the glued ends apart again.I have sinced used the glue on hundreds of applications with the same results. The only thing I found unusual about the glue is you have to keep it in the freezer or it looses its power quickly and becomes like water. Here is the dial with glued feet | ||||

|

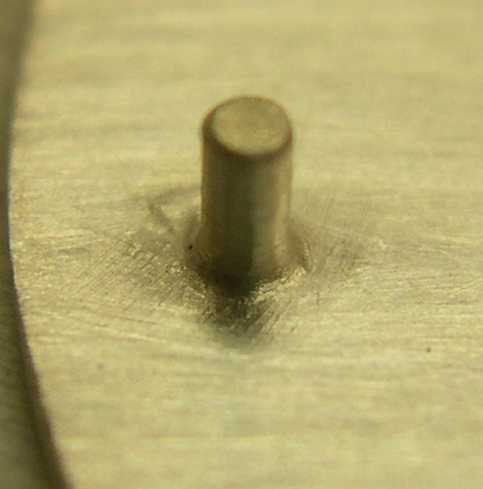

Here is a close up of one of the feet: | ||||

|

| IHC Life Member |

Ernie, that is a great testimonial for your project and as the old saying goes, "the proof is in the pudding".... Is there any Engineering data available on the glue and it's adherance properties of metal to various other materials...? something that could be use to determine the tensile strength of the bonded items, such as metal to melamine or other dial materials that we sometimes need to work with.... Years ago in my metal working days, we used a method to weld studs to the backside of aluminum plates that was called 'cold soldering' and this method would not disturb the finish on the front side of the plate at all.... I will see what I can find, if anything, regarding this proceedure and do another post if I am successful.... Keep up the good work, though, maybe you have something that will work quite well.... Regards, Jerry | |||

|

Jerry: According to the fact sheet that came with the glue it has a shear strength of 1500 PSI. Here is an exerpt from the fact sheet. | ||||

|

| IHC Life Member South-Bend |

Thanks much for that info Ernie. I had some dials made a number of years ago and they welded the feet on. They did a pretty good job. Silver to silver weld.  | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Is anyone repairing feet on a Dial

Is anyone repairing feet on a Dial

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Is anyone repairing feet on a Dial

Is anyone repairing feet on a Dial©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide