| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Roller Jewel Pin

Roller Jewel Pin

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Roller Jewel Pin

Roller Jewel PinGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Is it easier when replacing a roller jewel pin to remove the roller first, and insert the pin, and then replace?  | |||

|

| IHC Life Member |

Wayne, You can use a multipurpose tool to heat the roller in place. However, you could over-heat the blance staff and reduce its temper. IMHO, I would remove the roller using a good roller remover tool, such as the Rex roller remover set. This tool has different size stumps and punches so that you can remove the roller without damaging the staff pivot. I would shy away from the Swiss type. If the roller is tight, you can damage the balance when the roller pops off. Also, does your balance need truing? It looks a little out of whack in your picture (1:30 area). John D. Duvall Rosamond, CA. NAWCC Member 0144772 NAWCC IHC Happy Camper 192 | |||

|

| Watch Repair Expert |

It IS easier to re-set a roller jewel with the table removed. And for what it's worth, the balance wheel above has one of it's rim halves caught on bottom of the other, which is a result of very rough handling. ------------------ Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas | |||

|

I have noticied that several different locations for the roller jewel pin? Are they adjusted per individual balance?  | ||||

|

| IHC Life Member |

Wayne, I make it a practice to position the table so that the roller jewel is 90 degrees to the balance arm. There are two reasons for this: 1. I know where the roller jewel is at when I install the balance which makes it easier to mate it with the lever fork. 2. The watch will be in beat or very close to it when the balance is at rest and the balance arm is at a right angle (90 degrees) to the pallet lever. If you decide to reposition the table, you will need to turn the hairspring to bring it back into beat. I hope you're not confused by my explanation. Steve is the resident expert here and I'm only sharing what works best for me. Steve, am I out in left field on this one? John D. Duvall Rosamond, CA. NAWCC Member 0144772 NAWCC IHC Happy Camper 19 | |||

|

Thanks Steve & John for some excellent advice. | ||||

|

| Watch Repair Expert |

What really matters is the relative positions of the hairspring stud and the roller jewel; that's what puts the watch in beat. Essentially, the hairspring in a watch serves as an "artificial gravity source," to return the pendulum (balance wheel) to center. When a watch is out of beat, it's exactly the same situation as when a pendulum clock is out of level. Ideally, the roller jewel should be at a right angle (from the center of the staff) to the spoke arms. That places it in the middle of one side, which makes it easier to view its interaction with the pallet. Once the roller table is removed and then reinstalled, the beat is adjusted by turning the hairspring collet (by inserting a sharp instrument in the slot in the collet). With NO power on the gear train (the mainspring completely relaxed), the balance wheel should come to rest so that pallet fork is exactly in the middle of the banking pins. That's difficult to judge, but as long as it's close that's usually sufficient. For absolutely perfect beat adjustment, a timing machine is required, but dead-perfect beat isn't essential for good timing. As long as the beat is within a degree or two or "ideal," there won't be any difference in the timing. -------------------- Steve Maddox President, Chapter #62 North Little Rock, Arkansas | |||

|

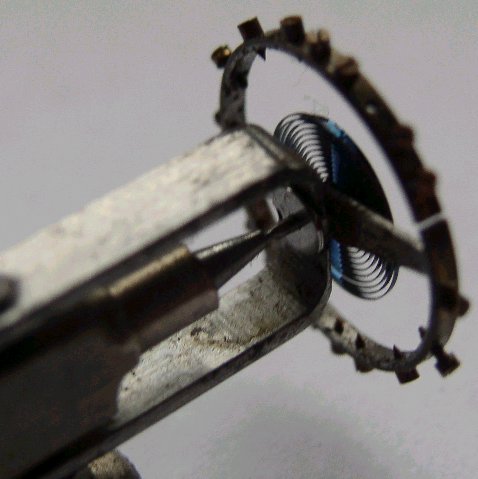

Would this type of tool work well to remove the roller plate?  | ||||

|

| Watch Repair Expert |

That's not my favorite type, but it should do the job! -------------- SM | |||

|

| Watch Repair Expert |

By the way, Wayne, how many different watches are you working on at the moment? The balance wheels in the images above are clearly from 2 different watches. -------------------- SM Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas | |||

|

One more roller jewel pin question, it seems like most of the pocket watches I find a flea markets/tag sales/etc have a missing/broken roller jewel pin. Is there a common problem that causes them to break, or fall out? Thanks | ||||

|

| IHC Life Member |

Wayne, I've never used the roller removal tool you have pictured. Does it have just the one end that fits against the balance pivot shoulder? If you intend on using the balance staff again, make sure the opening isn't too small and the nose is rounded. I use a Rex roller remover that comes with round nosed stakes that have .11, .15, .20mm hole openings. It was designed so that you could remove the roller table without damaging the staff pivot. If yours is designed for pocket sizes, it probably has an opening somewhere between .15 & .20mm. Some staking sets have roller remover stakes and punches included. A broken roller jewel could be caused by rough handling. Someone may have rocked the watch back and forth violently in an attempt to start it running or simply dropped it on a hard surface. A missing jewel could be the result of soaking the balance in a cleaning solution causing the shellac to soften. Also, an improper or improperly set jewel will eventually come loose. With my limited experience, I've found most roller jewel installations to be quite robust. Many non-working watches that you find for sale have been botched repairs. I'm still looking for a pair of pallet jewels for an old key wind that someone tried to clean while it was assembled. John D. Duvall Rosamond, CA. NAWCC Member 0144772 NAWCC IHC Happy Camper 192 | |||

|

Thanks John for the information. This tool appears to work well, but I just got a Rex Roller removal tool, so will try it next.  | ||||

|

Another roller remover tool.  | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide