| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  HAirSpring collet 90 deg. Ahead of the Balance Bridge Port

HAirSpring collet 90 deg. Ahead of the Balance Bridge Port

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  HAirSpring collet 90 deg. Ahead of the Balance Bridge Port

HAirSpring collet 90 deg. Ahead of the Balance Bridge PortGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Hello, Today I inspected why a Roller Jewel was prohibiting the pallet fork from banking left. Between the plates I could see the jewel had left ‘the fork’. I reinserted the balance wheel being careful that the notch was in line with fork. After holding the balance bridge , resting in the bezel, over the correct positioning I could clearly see the collet needs a great amount of repositioning. I have some tools but not sure of a safe way to grab or clamp the balance wheel to turn the collet. I believe there is one for minor adjustments while the watch is assembled. Used for beat adjustment. My collet is not there yet! How can I get the hairspring stud where it needs to be? ThankYou for All. | |||

|

Well My staking Strategy for tightening the Collet with a concave punch, followed by a Lil’ bit to much wood mallet. Is it beyond repair? I wish I knew how to bring in all the photos with an album link with imgur. But here is the album showing the mangled balance wheel. But the Collet is tight..LOL http://imgur.com/a/cZNrDdt | ||||

|

| IHC Member 1555 |

enough said | |||

|

Lesson learned. Looks like you are holding the balance in a truing caliper. Unless you have another or better plan gently begin to work the balance back to level and be careful with the balance pivots. Good luck. Rob | ||||

|

Well, I guess we all learn by making mistakes. It would be best to read the section on truing a balance wheel in your Chicago school of horology you down loaded. It is important to true the balance for timekeeping. Also, watch your pivots as stated above. Good luck, Mick. | ||||

|

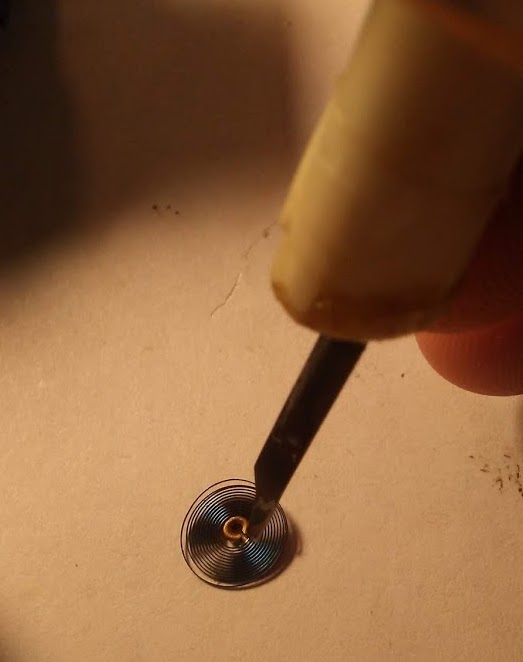

It looks like 2 things or 3 , 1 treat a balance and hairspring like a live bomb , 2 close collet with spring off balance , 3 use tool to adjust collet , that will keep you busy but it can be straightened , try this tool made from old mainspring heated to take out temper , grind the tip to shape, epoxy in old ink pen tube  | ||||

|

use like this , just imagine it is on the balance , I hope this is what your asking , I get accused of telling you how a watch works when you only wanted the time  | ||||

|

Yepper. When I did the damage the collet had gone through the concave punch step, off the wheel. I used a hole punch makng sure the pivot had space. Even the lightest tap THEN INSPECT, need more? Another light tap, INSPECT. The closing distance is real small. I treated it like the wheel arms WOULD NOT DEFORM in the hole really too big in the Staking anvil. I need next time to think of the best way to support the staff very close to the force, and make the balance arms not be the recipient. I must of hit it 3-4 times never looking, figuring it ‘would bottom out’. Sadely it was home probably on the first hit. Then after those 3-4 I gave it ONE LAST ONE. So now I have a few 7j Grade 96 Elgin 18’s to decide who become the doners! I LUV it. The tool You made from a main spring is a great mod with a part that would just get tossed. | ||||

|

| IHC Life Member |

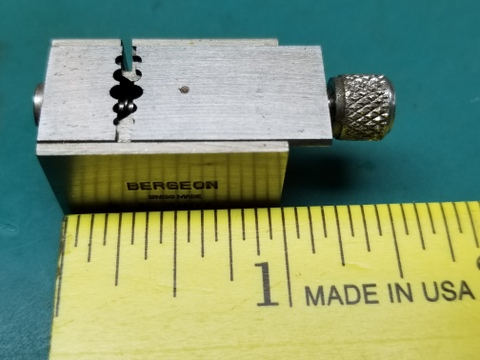

For every job there is a tool or many tools from different suppliers. After you've spent thousands of dollars on tools you'll think you have all you need, but you don't if you get addicted. Here is a Bergeon hairspring collet closing tool. And if you need to rotate the collet on the balance staff, there are tools for that too.  | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  HAirSpring collet 90 deg. Ahead of the Balance Bridge Port

HAirSpring collet 90 deg. Ahead of the Balance Bridge Port

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  HAirSpring collet 90 deg. Ahead of the Balance Bridge Port

HAirSpring collet 90 deg. Ahead of the Balance Bridge Port©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide