| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Hard to wind - fixed

Hard to wind - fixed

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Hard to wind - fixed

Hard to wind - fixedGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Member 1736 |

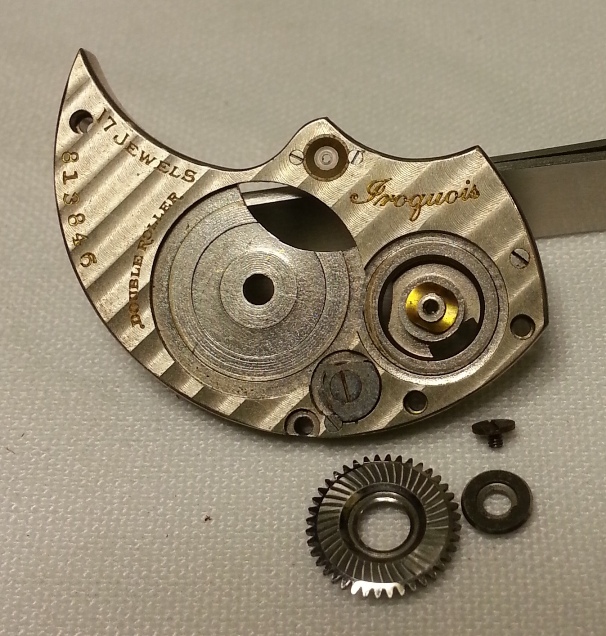

I bought an Iroquois with broken teeth on the click wheel. A week later, a parts movement became available and I was off to the races. With the watch back together, it was still unusually tough to wind. I knew I did not have a stem riding on the case issue, wasn't a dust ring alignment issue... So, I started working backward, one rotating part at a time... and found that, with the barrel plate removed and nothing but the winding wheel installed... the center bushing for the winding wheel was binding it to the barrel plate when the center screw was torqued. Some of the Waltham's I've had apart have a shim here, under the center bushing. A triple zero dial washer fit like a champ and gave me just enough clearance to free the winding wheel and not affect the engagement to the stem. Pardon the grime, this is the plate from the parts watch.  | ||

|

| IHC Life Member |

I have been intrigued by the use of shims on all Illinois, but never on Elgins. Interesting difference with machine capability of the two different (and otherwise very capable) companies. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide