| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Gold cups?

Gold cups?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Gold cups?

Gold cups?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Member 163 |

I'm sure this is probably a basic, newbie kind of question, but here goes anyway... NAWCC Member 157508 NAWCC-IHC Member 163 | ||

|

Raised Gold jewel settings are for looks only I believe. Aaron | ||||

|

| Watch Repair Expert |

They don't make the finger work any better, but they sure make it look better! Seriously, gold jewel settings are just "niceties," like the fancy damascening patterns on plates, mirror polished steel work, etc. All those features are considered part of the overall "finish" work of the watch. At some point, there's only so much that can be done to a functional item to improve its functionality. After that, the rest is just icing on the cake, so to speak. It's no different with automobiles, or anything else; a Mercury Marquis isn't any better car than a Lincoln Town Car, but the Town Car has more bells and whistles. Still, you gotta admit, watches like the one below do look good! =========================== Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

| Watch Repair Expert |

I guess it would help if I would attach the file! | |||

|

| IHC Member 163 |

Interesting. Thank you for your comments. I had always thought they must have had SOME form of functionality, considering they're located at the pivot point of the moving parts of a watch...a reducer of natural magnetism from the spinning steel pivot? Guess it's not as 'H.G. Wells' as I thought. (grins) Once again, appreciate the info. Regards. Mark NAWCC Member 157508 NAWCC-IHC Member 163 | |||

|

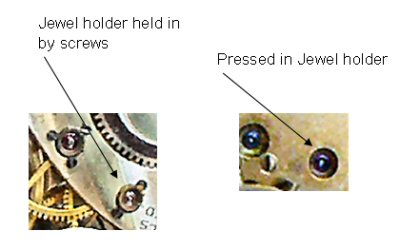

Comparision of screw held jewel holders vs pressed in jewel holders:  | ||||

|

| IHC Member 163 |

I've been waiting to see if anyone else either agreed or disagreed over the past few days, but apparently this is the accepted answer. I'd sure like to have been a fly on the wall when THIS idea was first introduced... We see an engineer run into his bosses office...' 'Boss, I've just had a GREAT idea. How about installing gold cups with our jewels?! It will probably cost us more in machining time, just in case the current drilled holes aren't big enough to handle the cups, or we could use smaller jewels...and instead of just pressing them in, we'll have to have each installer put in anywhere from 2 to 3 extra screws to hold them in place, so there will be more parts involved and more bench time in final assembly....and they don't make the watch RUN any better, and no one will probably ever see them but the watchmakers and jewelers who service them.... but won't they be purty when we're done??!!!" Uh, 'sure, let's do it!', says the boss, and the rest is history? Maybe so, maybe so.... NAWCC Member 157508 NAWCC-IHC Member 163 | |||

|

| Watch Repair Expert |

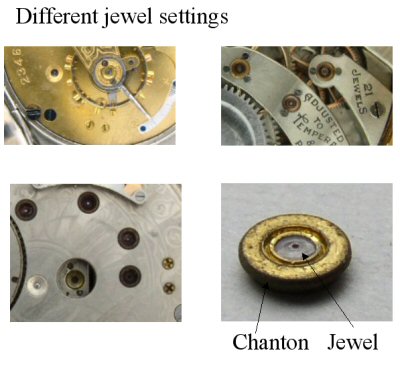

"Boss, I've just had a GREAT idea..... We're going to take finished automobiles, drill hundreds of holes through the body panels, and install bright, shiny chrome strips all over them. They won't make the cars run any better, but won't they be purty when we're done??!!!" While gold jewel settings in watch movements have no practical advantage over brass, they were considered "marks of distinction" among quality watches, at a time when most buyers DID see the movement they were purchasing before it was installed in a case. Think of them like white sidewall tires, or chrome trim on an automobile; their most useful "purpose" was to help sell the product. The correct terminology for a metal band that surrounds a jewel is a "jewel bezel," although in the world of horology, it's commonly accepted to refer to those as "jewel settings." Bezel-set jewels in watches have been around for a long time, although I really don't know who introduced them, nor how long ago that was. The earliest American example I have dates from 1853, but the British had been using them for a number of years prior to that. My guess would be that in America, gold jewel settings were introduced by the Nashua people, and subsequently used on the higher grade Waltham products (such as the "American" grade 1860 KW shown below). Like damascening, gold trains, and mirror polished steel work, gold jewel settings eventually became accepted as a mark of quality among high-grade American watches. Essentially, there are three different types of jeweling, namely burnished, bezel-set, and friction jeweling. The earliest form was the "burnished" type, which is shown in Wayne's image above (and incorrectly labeled as "Pressed in Jewel holder"). Jewels mounted in that way are installed from the bottom into holes surrounded by deep grooves, and the metal at the edge of each groove is "burnished" (essentially riveted) over the perimeter of the jewel to hold it in place. Needless to say, the disadvantage to that method is that it made it very difficult to replace broken or damaged jewels, and the "bezel-set" method eventually supplanted it in most high-grade watches. Bezel-set jewels are also burnished into the metal surrounding them, but instead of being mounted directly into the plates, the jewels are set in small cylindrical bezels, which are usually affixed to the plates by tiny screws. The majority of jewel bezels are brass, although on high-grade watches, gold jewel settings were often used as marks of distinction. The final type of jeweling to be developed is called "friction jeweling," and jewels of that type are literally "pressed" into holes, and held in place by friction. Of course, friction jeweling requires tight tolerances that were difficult to maintain in the old days, and it requires synthetic jewels that can withstand constant peripheral pressure, which would eventually break a natural jewel. Friction jewels can be mounted either directly into holes in the plates, or into bezels, which can then be mounted in the plates either by friction, or with screws. In appearance (from the top), friction jewels typically look similar to burnished jewels, but they're usually deep red in color, while burnished jewels are more often pink or nearly clear. I hope the majority of people asking questions here are pleased to have an opportunity to learn something, and are not disappointed by failure to incite disagreement or debate. In horology, like anything else, divergent opinions often exist, but as John Duvall's "trivia" questions so plainly exemplify, because the mechanical aspects of it are scientific, the number of correct answers is usually limited. =============================== SM | |||

|

| IHC Member 163 |

That's why I asked the question, Steve. I really didn't know. Not sure what you meant by that last paragraph, as I'm not looking for a debate...was that aimed at me? p.s. Just to explain why I ask these questions...I have no interest in debate or 'inciting disagreement', as possibily supposed by Steve. I work in a University engineering management department, taking care of the distance learning requirements. One story told here is of a girl beging to learn how to cook, and her mother showed her how you roast a pot roast. Before she placed it in the pot, she cut the end off the roast. The little girl asked her mother 'why did you cut that off?' The mother replied, 'I believe it's for presentation, but that's how MY mom taught me. Let's ask her.' They called the grandmother, and she said, 'You know, I really don't know myself. I always thought it was for presentation purposes, but grannie taught me that way. Let's call her at the retirement home.' They called grannie. 'Why did I cut the end off the roast? Well, I never had a pot long enough to put an entire roast in, so I always had to cut the end off before I could get it in the oven!'. Moral of the story, never just take things for granted, as though there seems to be an obvious answer, sometimes there was a completely different reason for the original idea. THAT'S why I asked the question about goldcups, something rarely seen by an owner of a watch. If that makes me obstinent, I apologize. (but I won't stop asking those questions! NAWCC Member 157508 NAWCC-IHC Member 163 [This message was edited by Mark Cross on November 13, 2003 at 17:09.] | |||

|

| Watch Repair Expert |

Hi Mark! "Not sure what you meant by that last paragraph, as I'm not looking for a debate...was that aimed at me?" No, not really, but you did say: "I've been waiting to see if anyone else either agreed or disagreed......" and I suppose I just didn't understand where you saw much potential for disagreement about the "purpose" of gold jewel settings. Questions like: "What is the meaning of life," are bound to elicit divergent opinions, but when the question is about a simple mechanical feature, it doesn't seem to me as though there's much room for dissension. Most screws tighten clockwise, and loosen counterclockwise, and that's about all there is to say about that. Right-handed screws aren't "better" than left-handed ones, but there are only two possible directions a screw can turn, and one way became "accepted" simply to avoid confusion. It's the same reason people in the Army are taught to turn in the same direction while doing an about-face. As for the "purpose" of gold jewel settings, I still think you're underestimating their importance as selling points. If nothing else, it gave the sales clerks something to chat about with their customers, and it was something simple enough that every customer and every clerk could easily understand it. Not everyone would know what a "double roller" was, nor a "safety pinion" or a "motor barrel," but everyone knows what GOLD is, and more is almost always considered better! In addition to the "impact" the idea had on the buying public, it's important to consider the opinions of watchmakers. Even today, people often ask my opinion about watches, and I'm sure a certain percentage of those people are influenced by what I tell them. Assuming a similar situation has always existed (and I can't see why it wouldn't have), it stands to reason that a favorable impression held by watchmakers would eventually translate into better sales for watch companies. In my opinion, that's the reason the plates of high-grade watches are damascened in places where only a watchmaker would ever see them, but that's really just a guess. All I can say for certain is that damascening serves no mechanical purpose, regardless of where it's applied, but everyone seems to like it (including me). It's probably worth considering that at the time when most American pocket watches were produced, pure 24k gold was $20 per ounce. The total amount of gold used in a high-grade pocket watch would be less than 1/100 of an ounce, and that would be karat gold, which is typically less than 50% pure. Needless to say, by doing the math, it's easy to see that the amount of gold used in a watch didn't amount to a significant investment (about 10 cents worth for an average watch), and it's probably roughly equivalent today to the gold that's used to plate the connector terminals on most "high-grade" computer cables. MANY wristwatches have solid gold markers on their dials, and some even have solid gold hands. I don't know of any company that ever made a selling point of that fact, but the relative cost was so insignificant that the quality companies just did it. Many of the better Hamilton wristwatches from the 1940s and 50s even had Sterling silver dials, with solid (karat) gold numerals, but while that might sound impressive, there's over twice as much silver in a silver quarter, and at least twenty times as much gold in a typical fountain pen point of the day. Trust me..... There is no practical purpose for solid gold numerals on dials, nor for gold jewel settings in movements, nor for many of the other "niceties" that are commonly found in "high-grade" watches. While it's true that most companies attempt to "economize" as much as possible, every decision is ultimately made with the intention of making more money, and the most direct way to accomplish that is to promote sales. It doesn't really matter how much a company saves in production costs, if a competitor's product sells while theirs remains on the shelf. That's really the bottom line, both figuratively and literally. ============ Best regards to you too, Mark, and please don't stop asking questions that interest you, even if you don't always like the answers you receive! SM ---------- PS -- If you still think gold jewel settings were "extravagant," take a look at the dial-side pillar plate of the Illinois "Sangamo" in the images below, and try to imagine how much THAT cost the company. Even if the pattern was entirely machine made, the machine had to be purchased and powered, someone had to operate and maintain it, and it caused an extra step in the production process. Surely all that couldn't have been accomplished for less than 10 cents per movement, even in those days, and only a watchmaker would typically ever see it! | |||

|

Steve points out that there's only so much that can be done to a functional item to improve its functionality; after that the rest is just icing on the cake. Are there particular American mechanical pocket watch make-model-grades that come to mind as classic examples of no-frills plain-Jane movements that excelled in the kind of timekeeping precision required by railroad service? (I think this is the same question a trainman might have asked if he wanted only the most time-service bang he could get for his hard-earned buck.) | ||||

|

| IHC Member 163 |

Thanks Steve, Dog. I never said I didn't like the answer, nor implied it anywhere in my replies. If it appeared that I did, I'm sorry, I had no intention for it to be read as such. I just asked if that was the ONLY answer. From the lack of any other replies, I'm coming to the conclusion it must be. Just to make one more example of why I follow my chain of thought (you brought this one up Steve (grins)), you mention how screws, either right hand or left hand, really make no difference in the final conclusion. (I'm paraphrasing, and probably COMPLETELY misunderstanding your example, of course Ok, enough rambling. Thanks again all for your information. I'll move along in my quest for obscure knowledge. Regards. Mark NAWCC Member 157508 NAWCC-IHC Member 163 | |||

|

| Watch Repair Expert |

Dog -- No-frills, plain-Jane, American mechanical pocket watches that excelled in timekeeping precision? No, not really, although several companies did offer at least one model that was "basic" in comparison to their others. For Waltham, it was the "645" and "845" models. For South-Bend, it was the "227" models, which at the time they were produced, were the cheapest watches on the market that met minimum RR requirements. Elgin usually offered at least one "Elgin Nat'l..." model that met minimum RR standards, but was cheaper and not as nicely finished as their BW Raymond, Father Time, or Veritas models. All of those models used essentially the same basic parts, but the higher grade (and higher priced) models had more "frills," such as gold jewel settings, gold (or gold filled) gear trains, double-sunk dials, fancier damascening patterns, etc. I don't think that ANY company wanted the reputation of producing "basic" railroad watches. All of them were trying to achieve the sort of reputation that Rolex has today, and as I'm sure you know, while some Rolex models cost more than others, they don't want any of their models to be perceived as "cheap." ------------ Mark -- Here's some additional obscure information for you: Mopar products weren't the only ones that used left-handed lug bolts and nuts on left-side wheels. I have a '63 Pontiac that's the same way, and all the wheel studs on the left side have a big "L" stamped in the center to alert servicemen to that fact. Needless to say, the meaning of that is lost on most people at tire shops these days, and I always have to remember to mention it in advance so they won't strip a nut with a 300 pound pneumatic impact wrench. Not too long ago, one of my old left-handed lug nuts finally did strip out, and I ended up at NAPA, where I decided it was prudent to buy a whole new set of both lefts and rights. NAPA also had left and right-handed studs, and I seriously considered buying a set of right-handed studs and installing them in the left-side hubs, but I decided instead to just leave them alone. I suppose that in every "modern" instance where left-handed threads are used (as in many crown wheel screws in watches), there's some sort of perceived reason for that necessity, although in reality, I think some of those uses are rather dubious. In watches, most (although not ALL) left-handed screws have three parallel slots cut in the head, which is to alert the watchmaker to the fact they're left handed. Most people working on watches know what that "code" means, but not ALL left-handed screws have it, and a lot of them get broken as a result. Particularly on crown wheel screws, calendar nuts, and castle wheel screws on chronographs, if a screw won't loosen in the usual direction, it's a good idea to try it in the opposite direction first before applying more pressure. I'm sorry if I appeared "cross" with you, as that was never my intention! ===================== SM | |||

|

Steve M. Because of the edit time setting I cannot delete my post "Comparision of screw held jewel holders vs pressed in jewel holders". If one of the Forum Moderators could delete this post I would appreciate it. | ||||

|

| IHC Member 163 |

See there! I learned something new AGAIN today here. I didn't know MOPAR's weren't the ONLY crazies who did that. Great minds and all that? (grins) Thanks Steve! No problems at all. Wayne, I really wish you wouldn't have those photos removed, unless you really need them gone. I found them of GREAT use in seeing side by side comparisons of friction vs. gold cup settings, and thank you for doing that.I've never seen them in that kind of comparison. I forgot to say that in the posts above, and apologize for not doing so. High regards to all who 'talked' with me. I enjoyed the exchange and new information. Mark NAWCC Member 157508 NAWCC-IHC Member 163 | |||

|

| Watch Repair Expert |

Wayne, I'm with Mark; I'd hate to see you delete your message above, but perhaps now that you've learned more about the different types of jeweling, you might consider posting an updated image showing all three types with the correct terminology. I'm sure a lot of people here would enjoy that, and I don't have the photographic equipment to do it. Anything old and Swiss is likely to have burnished jewels, while anything late-model (BW Raymond 571, Hamilton 992B, etc.) is likely to have friction jewels, at least in the gear train. ==================== SM | |||

|

| IHC Life Member |

Wayne, Send me an updated picture and I can change it for you. The title too if you want. Just let me know what you want. John D. Duvall Vice President, Education | |||

|

Is Chanton the correct name?  | ||||

|

| Watch Repair Expert |

The word "chanton" doesn't mean anything in any language I've been able to research. In French, however, the word "chaton," means "kitten." Now, I'm not sure how the French manage to go from "kitten" to "bezel," but Donald DeCarle's "Watch and Clock Encyclopedia," provides the following definition: CHATON (French). A bushon, or a bezel or ring. In horology it refers to the ring or bushon into which is set a jewel hole, etc., or a metal bushon where the hole is relatively small. Some watches are fitted with brass chatons to the center and other wheels, the object being that they can be renewed. They are usually fitted friction tight (no riveting). Now, to translate from "British" to "American" English, a bushon is a bushing, a jewel hole is a hole jewel, and renewed means replaced. The term "jewel hole," as used by the Brits, seems very odd to me. I know how to measure a jewel hole, but how could one be replaced? It rather reminds me of the old riddle: If it takes three men three days to dig three holes, how long would it take one man to dig half a hole? Of course, the answer is: It isn't possible to dig half a hole. ================= SM | |||

|

Although many of the best American watches (including Waltham) had raised gold jewel settings held by screws, for their VERY best movements, such as this ca.1898 "American Watch Co." grade, Waltham used friction set raised gold settings. (At this time their Riverside Maximus grade used screws to hold the settings). I expect it took tighter tolerances to hold these settings firm.  | ||||

|

| IHC Member 163 |

WONDERFUL information, my friends! I didn't know there were that many different jewel types! Thank you for those great photos. Pictures DO speak a thousand words! High regards. Mark NAWCC Member 157508 NAWCC-IHC Member 163 | |||

|

| Watch Repair Expert |

Jerry, Just out of curiosity, why do you suppose your "American" in the image above has flat, rather than arched-top wheel spokes? =============== SM | |||

|

Steve Maddox Are these the spokes you are referring to?  | ||||

|

Steve, I am not sure why, but all of the early high-grade 12-size Walthams that I have seen (Riverside Maximus and AWCo) have flat gold wheels in the gear train, including the center wheel. This seems to hold true for smaller sizes as well, and many of the earlier 16-size (such as 1872 model American Watch Co grades). | ||||

|

| Watch Repair Expert |

Wayne -- Those ARE the type spokes to which I was referring, and they're usually one of the "niceties" found on higher grade watches.. Jerry -- I didn't think about the watch in your image above being a 12 size. That obviously explains the flat wheels! ============== SM | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide